Cast-in-place pile construction method for underground engineering structure

A technology of underground engineering and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve problems affecting the quality of cast-in-situ piles, affecting the smooth progress of projects, engineering accidents and risks, etc., and achieve good control of risks, Guarantee the effect of stability and great applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

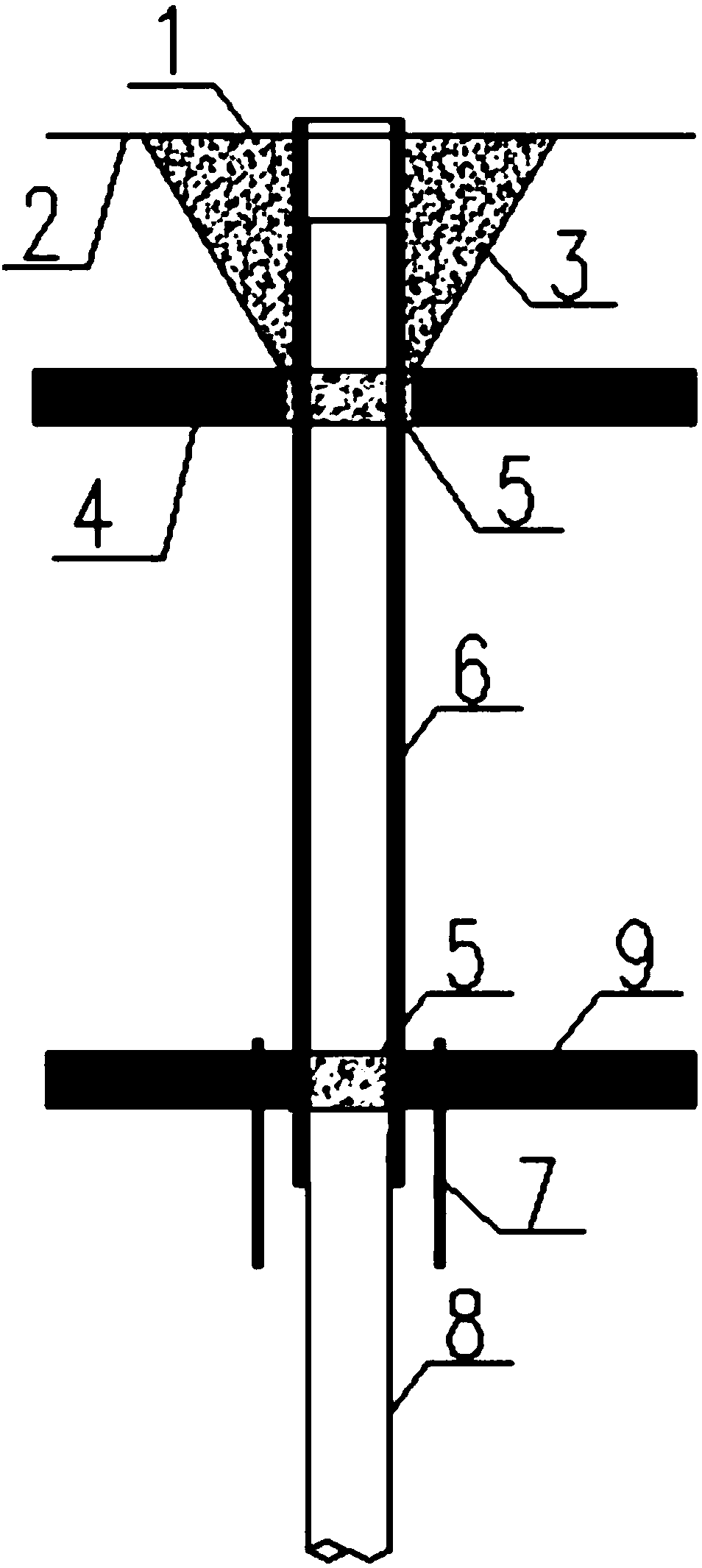

[0024] As shown in the figure, the present invention provides a construction method for cast-in-place piles for underground engineering structures, comprising the following steps:

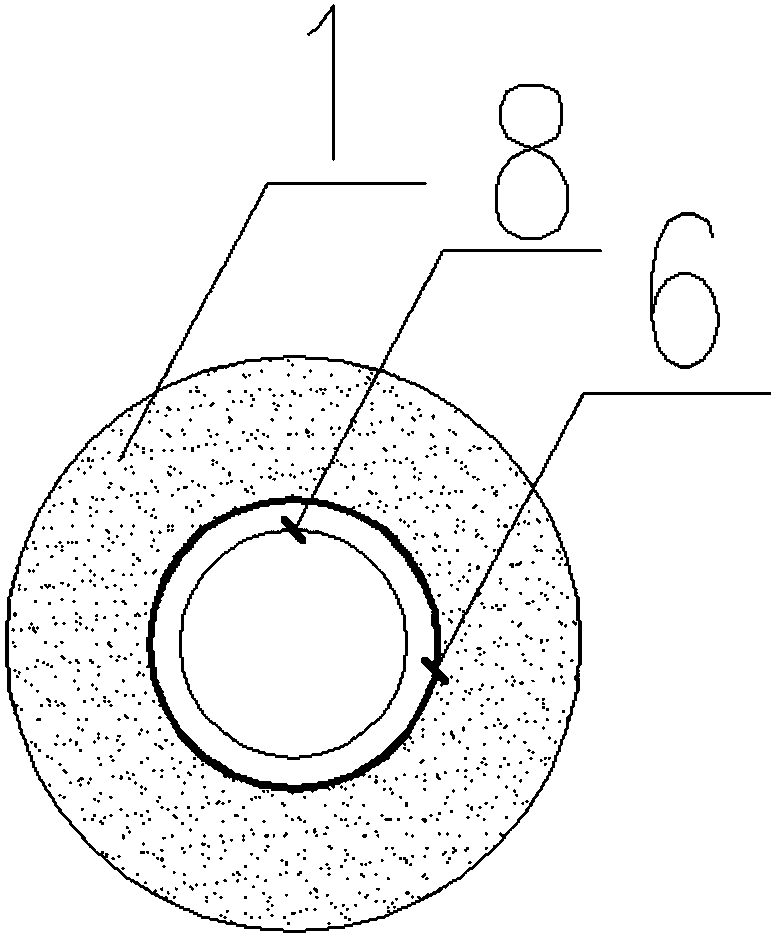

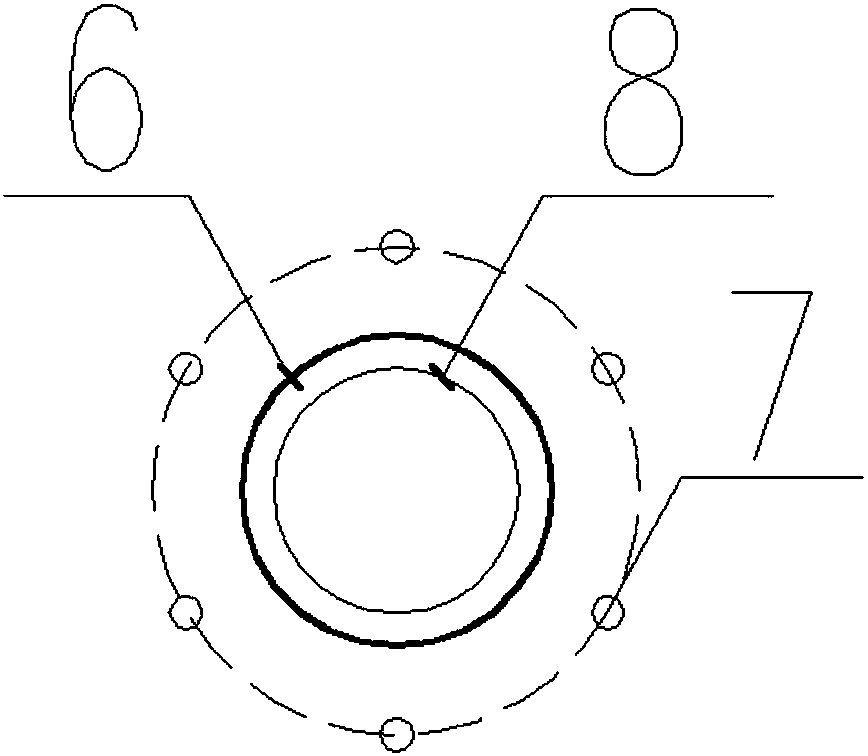

[0025] 1. Within the construction scope of the cast-in-place pile 8, excavate the soil 3 above the roof 4 of the existing structure on a slope; after excavation, the soil 3 above the roof 4 of the existing structure forms an hourglass-shaped pit body, and the exposed existing structure The area of the top plate 4 is larger than the section of the steel casing 6, so that the steel casing 6 can enter the existing structure top plate 4;

[0026] 2. Within the construction scope of the steel casing 6, it is ensured that the steel casing 6 can pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com