Preparation method of oxidized cellulose nanofiber membrane sheet with fast bleeding stopping function

A technology of nanofiber membrane and oxidized cellulose, applied in the field of medical materials, can solve the problems of slow hemostasis rate, etc., and achieve the effects of mild reaction, convenient processing and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

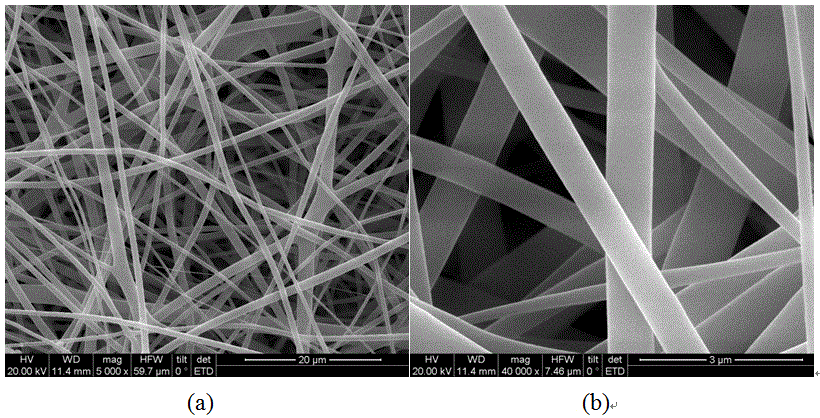

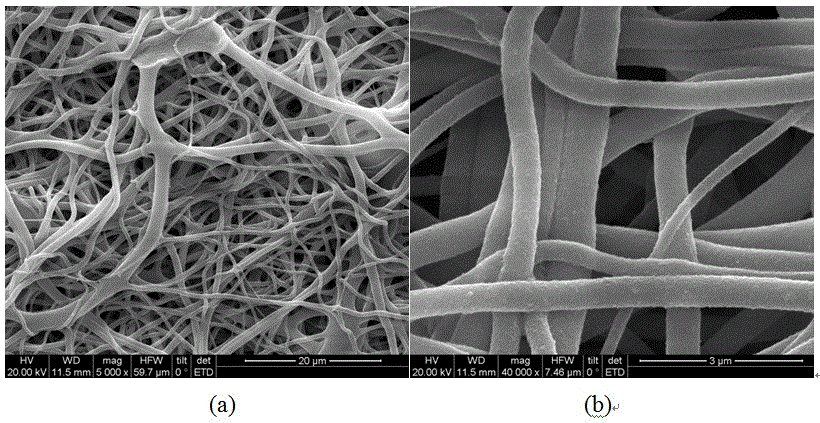

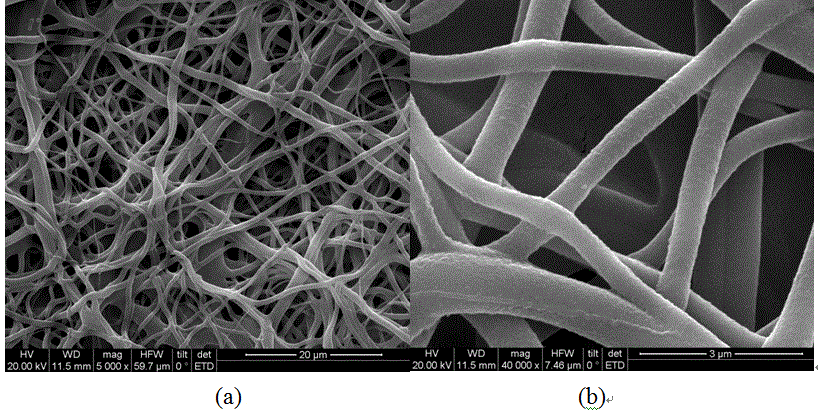

Embodiment 1

[0027] Cellulose acetate was used as raw material and dissolved in DCM / DMF mixed solvent to prepare a solution with a mass fraction of 11%, wherein the mass ratio of DCM to DMF was 2:1. Add this solution to the liquid tank of the electrospinning equipment, set the voltage of the DC high-voltage generator to 45kV, and the receiving distance between the electrode and the substrate to be 200mm, and a film (structural Such as figure 1 shown), the film was washed several times with deionized water and then vacuum-dried for further use. The cellulose acetate nanofiber film is immersed in NaOH / ethanol-water solution with a concentration of 0.1mol / L for hydrolysis, wherein the mass ratio of ethanol to water is 1:4, the reaction time is 24 hours, and washed with deionized water after the reaction Vacuum drying after many times to obtain cellulose nanofiber film (structure such as figure 2 shown). Weigh 0.1g of NaBr and 0.02g of TEMPO, dissolve them in 100mL of deionized water, plac...

Embodiment 2

[0030]Cellulose acetate was used as raw material and dissolved in acetone / DMAc mixed solvent to prepare a solution with a mass fraction of 12%, wherein the mass ratio of acetone to DMAc was 2:1. Add this solution into the liquid tank of the electrospinning equipment, set the voltage of the DC high-voltage generator to 45kV, and the receiving distance between the electrode and the substrate to be 200mm, and a film made of cellulose acetate nanofibers can be obtained. The film was washed several times with deionized water and dried in vacuum before use. The cellulose acetate nanofiber film is immersed in NaOH / ethanol-water solution with a concentration of 0.1mol / L for hydrolysis, wherein the mass ratio of ethanol to water is 1:4, the reaction time is 24 hours, and washed with deionized water after the reaction Vacuum drying after several times to obtain the cellulose nanofiber film. Weigh 0.03g TEMPO, 2g NaClO 2 Dissolve in phosphate buffer solution with pH 6.8, heat the solut...

Embodiment 3

[0032] Ethyl cellulose was used as raw material and dissolved in ethanol to make a solution with a mass fraction of 15%. Add this solution into the liquid tank of the electrospinning equipment, set the voltage of the DC high-voltage generator to 45kV, and the receiving distance between the electrode and the substrate to be 200mm, and a film made of ethyl cellulose nanofibers can be obtained. The film was washed several times with deionized water and then dried in vacuum. The ethylcellulose nanofiber film was immersed in KOH / ethanol-water solution with a concentration of 0.1mol / L for hydrolysis, wherein the mass ratio of ethanol to water was 1:4, and reacted at 50°C for 24 hours. After the reaction was completed, deionized After washing with water several times, vacuum drying is performed to obtain a cellulose nanofiber film. Weigh 0.1g NaBr and 0.02g TEMPO, dissolve them in 100mL deionized water, place the solution in an ice-water bath, and keep the solution temperature below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com