Method for preparing bio-coating on surface of magnesium alloy by combining laser shock with micro-arc oxidation

A micro-arc oxidation and laser shock technology, applied in anodizing and other directions, can solve the problems of difficult mechanical integrity, magnesium alloy matrix corrosion resistance, limited mechanical properties, etc., to increase physical and chemical properties, good biocompatibility, etc. and biological activity, beneficial to industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

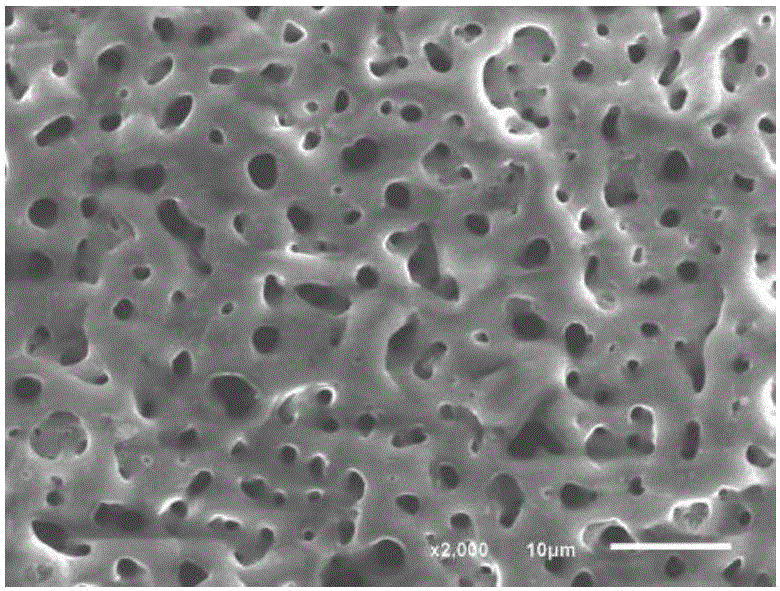

Image

Examples

Embodiment 1

[0027] The micro-arc oxidation reaction was carried out on the AZ80 magnesium alloy without laser shock treatment by using the micro-arc oxidation method.

[0028] Electrolyte concentration composition: Na 2 SiO 3 12g, NaF 5g, NaOH 5g, ethylene glycol 10ml, hydroxyapatite 3g, K 2 TiF 6 2g / L, deionized water 1L.

[0029] Specific steps are as follows:

[0030] (1) Pretreatment: Cut the AZ80 magnesium alloy substrate into rectangular sheets of 60mm×20mm×2mm, and polish them with 280#, 500#, 800#, 1200# metallographic sandpaper to remove surface oxides and surface scratches, and then test The samples were ultrasonically cleaned in acetone for 10 min, then washed with deionized water, and dried naturally at room temperature. A pretreated magnesium alloy (AZ80-BM) was obtained.

[0031] (2) Micro-arc oxidation: immerse the pretreated AZ80 magnesium alloy obtained in step (1) as the anode in the electrolyte, use the micro-arc oxidation electrolytic cell as the cathode, and use...

Embodiment 2

[0033] The combination of laser shock strengthening and micro-arc oxidation was used to generate bioactive coating on the surface of AZ80 magnesium alloy. The specific steps are as follows:

[0034] (1) Pretreatment: Same as step (1) in Example 1.

[0035] (2) Laser strengthening treatment: aim the laser at the surface of the sample, the area to be treated is 40mm×15mm on the surface of the sample, and the wavelength of the laser is λ 1 =1064nm, pulse width τ 1 = 20ns, energy Q = 2J, spot diameter D = 3mm, the laser spots are arranged in a continuous overlapping manner without intervals, and the coverage rate of adjacent spots is 50%. The processed samples were ultrasonically cleaned in anhydrous ethanol, taken out with deionized water, dried naturally, and finally sealed and packaged.

[0036] (3) Micro-arc oxidation treatment: the sample obtained in step (2) in Example 2 is immersed in the electrolyte as an anode, and the micro-arc oxidation electrolytic cell is used as a ...

Embodiment 3

[0046] The difference from Example 1 is: the AZ80 magnesium alloy is processed into such as image 3 The size shown, other operations are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com