Method for pretreating maize straws by utilizing NH4HCO3, and anaerobic fermentation method of maize straws

A corn stover and anaerobic fermentation technology, applied in fermentation, waste fuel and other directions, can solve the problems of poor treatment effect, waste treatment, high cost, and achieve the effects of difficult operation, high treatment cost and alleviating waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

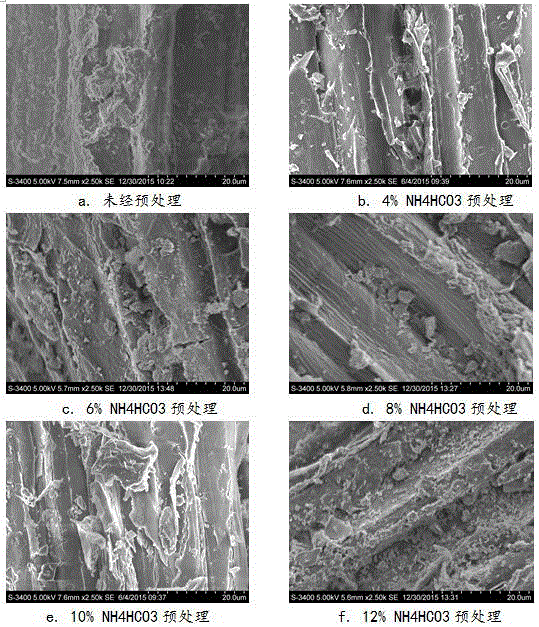

[0029] A use of NH 4 HCO 3 Methods of Pretreating Corn Stalks:

[0030] After crushing the corn stalks, pass through a 40-mesh sieve, weigh 88g and add 300mL of NH with a mass concentration of 4%. 4 HCO 3 Solution, just submerged the crushed corn stalks, mixed evenly and placed in a plastic bucket, treated with micro-oxygen at room temperature for 10 days (the plastic bucket is not completely sealed, air can enter), then add water and stir the treated corn stalks evenly After standing still, filter and dry for later use.

[0031] The method of anaerobic fermentation using the above-mentioned pretreated corn stalks is as follows:

[0032] Take the above-mentioned dry corn stalks for use in a fermentation bottle, add 200mL of inoculum, [the source of the inoculum: ordinary fresh cow dung (mainly using the methanogenic bacteria in cow dung) is added with water to prepare the TS concentration ( That is, the total solid concentration, the same below) is 8% of the fermentation ...

Embodiment 2

[0035] Joined NH 4 HCO 3The mass concentration of solution is 6%, all the other are with embodiment 1.

Embodiment 3

[0037] Joined NH 4 HCO 3 The mass concentration of solution is 8%, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com