Multi-cavity rotary inter-wall heat exchanger for hot semi-coke and coal

A heat exchange device, rotary technology, applied in the direction of indirect heat exchanger, heat exchanger type, moving pipe heat exchanger, etc., can solve the problems of increasing the burden of pyrolysis kiln and affecting the processing capacity of pyrolysis equipment, etc. , to achieve the effect of reducing the risk of fire and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

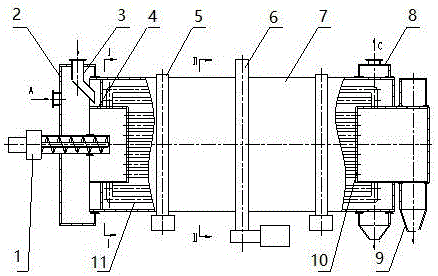

[0026] In order to overcome the need to reduce the comprehensive energy consumption in the coal pyrolysis process and improve the energy efficiency of the coal pyrolysis process system, the present invention provides such figure 1 Shown is a multi-chamber rotary partition wall heat exchange device for hot semi-coke and coal. This device adopts a multi-chamber rotary structure, and hot semi-coke and coal pass through different channels to realize partition heat exchange. After passing through this equipment, the semi-coke is cooled and lowered in temperature, and the coal is partially dried, and the temperature will also increase to a certain extent.

[0027] A multi-cavity rotary partition heat exchange device for hot semi-coke and coal, including a rotary cylinder 7, the rotary cylinder 7 is placed obliquely, and the feed end of the rotary cylinder 7 is higher than its discharge end;

[0028] The feeding end of the rotary cylinder 7 is sequentially connected with a semi-coke ...

Embodiment 2

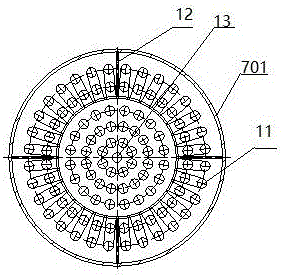

[0039] Based on the basis of embodiment 1, such as figure 2 As shown, in this embodiment, the rotating cylinder 7 includes a cylinder body 701, a heat exchange tube 11, a sub-chamber plate 12 and a support tube 13; the support tube 13 traverses the cylinder body 701 and is located in the cylinder In the middle of the cylinder body 701, there are multiple cavity-dividing plates 12, which are evenly located between the inner surface of the cylinder body 701 and the support tube 13; there are multiple heat exchange tubes 11, and they are located in the cylinder body 701 , the two ends of the heat exchange tube 11 are connected with the semi-coke collection box 10 and the semi-coke distribution box 4 respectively.

[0040] In this embodiment, four cavity-dividing plates 12 are used, and the cavity-dividing plates 12 are arranged along the length direction of the cylinder body 701 and are located between the inner surface of the cylinder body 701 and the support tube 13 at an angl...

Embodiment 3

[0045] Based on the above embodiments, in this embodiment, there are 20 heat exchange tubes 11 arranged in layers along the periphery of the inner cavity wall of the cylinder body 701 . The difference from Embodiment 2 is that the distribution of the heat exchange tubes 11 is different, and both distribution methods can meet the heat exchange requirements of the present invention. A plurality of heat exchange tubes 11 rotate together during the rotation of the rotary cylinder 7, thus forming a multi-chamber rotary structure, which can dry coal well and effectively.

[0046] The semi-coke feeding screw 1 is consistent with the center line of the rotating cylinder 7 .

[0047] The coal discharge chute 3 is located on the top of the kiln head box 2 , and the discharge chute 3 extends through the kiln head box 2 to the rotary cylinder 7 and communicates with the rotary cylinder 7 .

[0048]The feed end and the discharge end of the rotary cylinder 7 are respectively provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com