Method for preparing high-purity phycoerythrin through hydrophobic chromatography

A phycoerythrin and hydrophobic chromatography technology is applied in chemical instruments and methods, depsipeptides, peptides, etc., to achieve the effects of low cost, simple and easy operation method and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Centrifuge to collect 10 g of freshly cultivated Porphyridium algae, and fully mix the algae mud with phosphate buffer (pH7.0, 0.02mol / L) in a ratio of 1:6 to obtain a cell suspension;

[0018] (2) Place the cell suspension in a -20°C environment to freeze completely, take it out and place it at 4°C to thaw, and then place it in a -20°C environment after it is completely thawed, and repeat freezing and thawing 5 times to break the wall liquid; freeze and centrifuge the broken wall liquid, and collect the supernatant;

[0019] (3) At room temperature, the supernatant was ultrafiltered with a membrane bag of 60kD through a molecular cut-off, ultrafiltered 5 times, and the filtrate was collected to obtain a crude phycoerythrin extract;

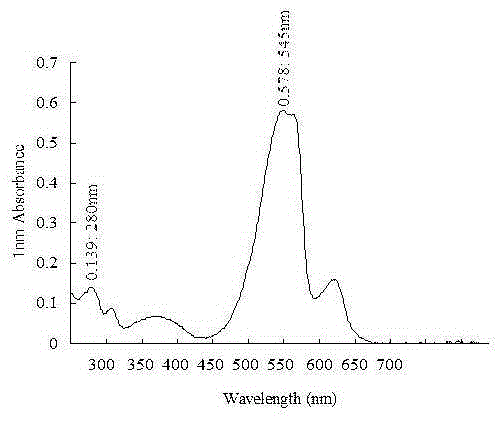

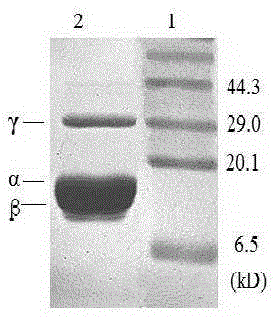

[0020] (4) Apply the crude phycoerythrin extract obtained in step (3) to a hydrophobic chromatography column, first wash it with 6 times phosphate buffer (pH7.0, 0.02mol / L), and then elute it with distilled water, collect A 545 / A...

Embodiment 2

[0023] (1) Centrifuge to collect 30 g of freshly cultivated Porphyridium algae, mix the algae mud with phosphate buffer (pH 6.8, 0.02mol / L) in a ratio of 1:5 to obtain a cell suspension;

[0024] (2) Place the cell suspension in a -20°C environment to freeze completely, take it out and place it at a temperature of 4°C to thaw, and then place it in a -20°C environment after it is completely thawed, and repeat freezing and thawing 6 times to obtain broken walls liquid; freeze and centrifuge the broken wall liquid, and collect the supernatant;

[0025] (3) At room temperature, the supernatant was ultrafiltered by a membrane bag with a molecular cut-off of 50kD, ultrafiltered 6 times, and the filtrate was collected to obtain a crude phycoerythrin extract;

[0026] (4) Apply the crude phycoerythrin extract obtained in step (3) to a hydrophobic chromatography column, first wash the impurity with 6 times phosphate buffer (pH 6.8, 0.02mol / L), then elute with distilled water, and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com