Device and method for synthesizing 2,2-bipyridyl

A bipyridine and pyridine technology, applied in the field of synthesis of 2,2-bipyridine, can solve the problems of high separation pressure, low utilization rate of pyridine, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

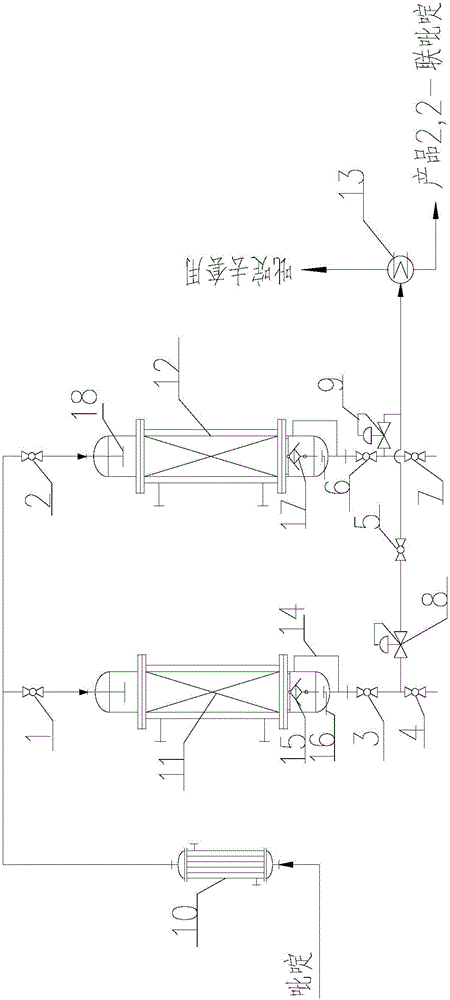

[0023] The 2,2-bipyridine synthesis process is that pyridine is transported by a pump, passes through a preheater, is heated to the reaction temperature, enters the reactor, passes through a liquid distributor, and is evenly washed onto the catalyst fixed bed Raney nickel on the catalyst bed, pyridine Liquid space velocity 2~4h -1 After the reaction, pyridine flows down through the catalyst support plate, and is discharged through the regulating valve. The reaction liquid enters the evaporator to distill the pyridine, recover and use it mechanically, and the residue is 2,2-bipyridine. The reaction conditions of Examples 1-4 and the conversion rate of pyridine per pass are shown in Table 1.

[0024] Table 1 Experimental data of 2,2-bipyridine synthesis

[0025] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com