Rear wheel housing for split type suv based on lightweight

A rear wheel cover, split type technology, applied in the upper structure sub-assembly, vehicle parts, transportation and packaging, etc., can solve the problems of poor molding stability of the main part, difficulty in ensuring the accuracy of parts, and heavy weight of the integral wheel cover. To achieve the effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

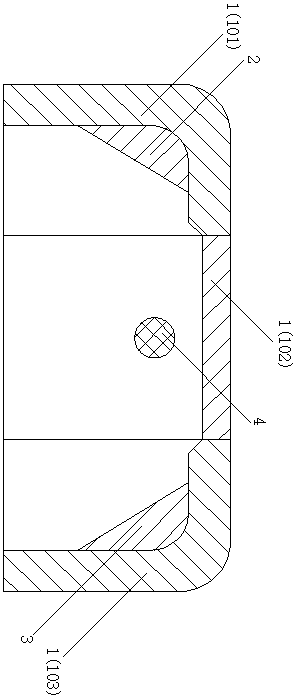

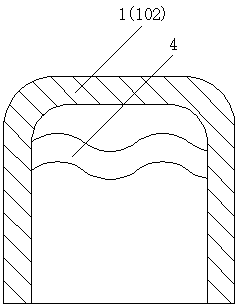

[0014] Such as figure 1 A rear wheel cover for a split SUV based on lightweight is shown, which includes a rear wheel cover body 1, and the rear wheel cover body includes a first end body 101 and a second end body 102 that are sequentially distributed in a horizontal direction. And the third end body 103, which are independent of each other; the inner side of the first end body 101 is provided with a front support end body 2 extending toward the front end of the rear wheel cover body 1, and the inner side of the third end body 103 is provided with a rearward The rear support end body 3 extends from the rear end of the wheel cover body 1; the second end body 102 is provided with a side support end body 4 which extends between the side ends of the rear wheel cover body 1, and the side support end body 4 A corrugated structure is adopted in the axial direction.

[0015] The lightweight split-type SUV rear wheel cover adopting the above technical solution divides the rear wheel cover...

Embodiment 2

[0018] As an improvement of the present invention, the thickness of the first end body 101 and the third end body 103 is greater than the thickness of the second end body 102.

[0019] The remaining features and advantages of this embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com