Recycling and regenerating process for waste textile containing polyester

A technology for waste textiles and processes, which is applied in the field of recycling and regeneration of polyester-containing waste textiles to achieve the effect of reducing the occurrence of side reactions and the formation of gels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

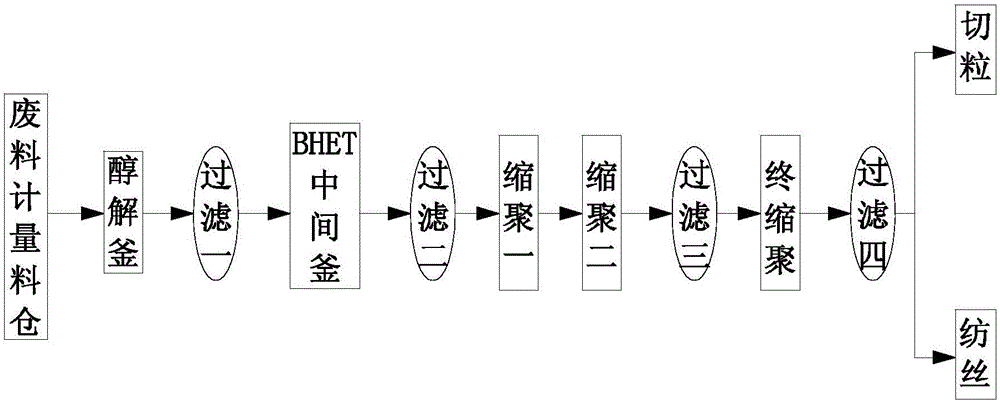

[0030] The waste regeneration process of this embodiment, combined with figure 1 , the technological process is as follows: the collected waste is pulverized→rinsing, drying→measurement→alcoholysis kettle→filter 1→BHET intermediate kettle→filter 2→polycondensation 1→polycondensation 2→filter 3→final polycondensation→filter 4→cutting Granules or spinning, the specific process is as follows:

[0031] (1) Crushing adopts impact cutting, combined with Figure 4 When the collected waste silk passes through the high-speed rotating roller 1 in a thin layer, the inclined blade 11 set on the rotating roller 1 contacts the waste silk, and in the process of instantaneous high-speed passage, the waste silk is cut into pieces by the inclined blade The inclination angle β of the inclined blade 11 is preferably 100-130 °, as in the present embodiment, the inclination angle β is set to 125 °, and the rotating speed of the rotating roller 1 is controlled at 60rpm-600rpm, as in the present emb...

Embodiment 2

[0039] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining Figure 5 , the crushing adopts a reciprocating cutter, which includes a frame, a hopper, a pressing roller, a wire feeding wheel 4, a reciprocating knife plate 3, a fixed knife plate 2 and a driving mechanism for a moving knife. The hopper is located on the frame, and its One end is provided with a lifting arm, and the other end is located in front of the press roller, and feeds the press roller. The wire feed wheel 4 includes an upper wire feed wheel, a lower wire feed wheel and a wire feed wheel located between the upper wire feed wheel and the lower wire feed wheel. The conveyor belt, the upper wire feeding wheel and the lower wire feeding wheel are located behind the pressing roller, the two are connected by a conveyor belt, the fixed knife plate 2 is installed on the frame behind the lower wire feeding wheel, and the reciprocating knife plate...

Embodiment 3

[0042] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining Figure 6 , crushing adopts a rolling knife sharpening structure. In this rolling knife sharpening structure, the knife body 5 is a cylindrical structure, and several knife grooves are arranged along its outer wall. The groove extends from the outer wall of the cutter body 5 to the axis of the cutter body 5 (but does not reach the axis) to form a groove-like structure with a large outside and a small inside, and the depth of the groove is not greater than the radius of the cutter body 5; a cutter is installed in the groove 51, the cutter 51 is diamond-shaped, one corner is located in the knife groove, and the corresponding other corner protrudes outside the cutter body 5; the filter screen 6 is a semi-circular structure, which is wrapped on the outside of the cutter body 5 in an inclined manner, and the filter screen 6 is provided with a V-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com