Surface treatment method of diamond micropowder for resin diamond wire saw

A technology of diamond micropowder and diamond wire saw, which is used in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve the problem of low bonding strength between resin adhesive and diamond micropowder, affecting the cutting performance of resin diamond wire saw, etc. To solve the problem, to achieve the effect of strong diamond holding force, stable wire diameter and diamond number, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

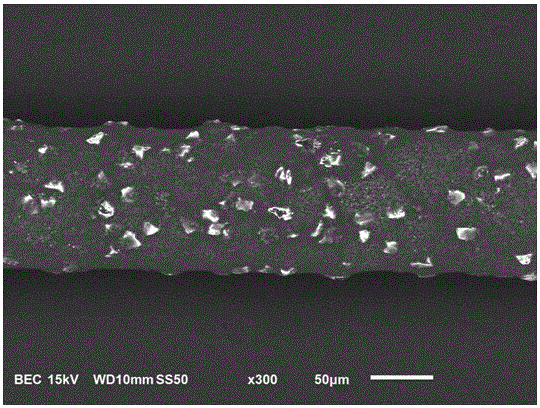

Image

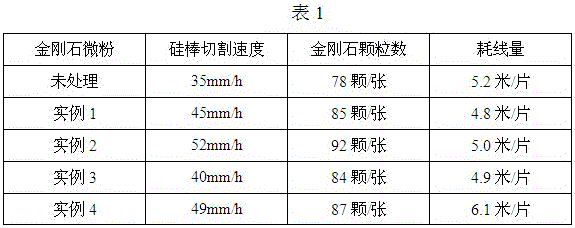

Examples

Embodiment 1

[0022] Weigh methanol, KH-550, 50 g, 10 g, and 10 g of pure water in beakers at room temperature, and stir the mixture with a magnetic stirrer to fully react for 4 hours at a stirring speed of 600 rpm. After the treatment solution is prepared, put it aside for use.

[0023] Mix the above treatment liquid with 30 μm diamond micropowder and put it into the reaction kettle, the mass ratio of treatment liquid to diamond is 3:1. Set the stirring speed of the magnetic stirrer to 600 rpm, the reaction temperature to 50° C., and the reaction time to 2 hours.

Embodiment 2

[0025] Weigh ethanol, KH-560, 65g, 13g, and 13g of pure water in beakers at room temperature, and stir the mixture with a magnetic stirrer to fully react for 5 hours at a stirring speed of 700 rpm. After the treatment solution is prepared, put it aside for use.

[0026] Mix the above treatment liquid with 30 μm diamond micropowder and put it into the reaction kettle, the mass ratio of treatment liquid to diamond is 2.5:1. Set the stirring speed of the magnetic stirrer to 650 rpm, the reaction temperature to 55° C., and the reaction time to 2.5 hours.

Embodiment 3

[0028] Weigh 70g, 14g and 14g of isopropanol, KH-590, and pure water in beakers at room temperature, and stir the mixture with a magnetic stirrer to fully react for 6 hours at a stirring speed of 800 rpm. After the treatment solution is prepared, put it aside for use.

[0029] Mix the above treatment liquid with 30 μm diamond micropowder and put it into the reaction kettle, the mass ratio of treatment liquid to diamond is 4:1. Set the stirring speed of the magnetic stirrer to 600 rpm, the reaction temperature to 60° C., and the reaction time to 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com