Preparation method of silver nano-dendrites

A silver nanometer and silver salt technology, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of toxicity, environmental hazards, and injury to experimenters, and achieve low energy consumption, low synthesis cost, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment relates to a method for preparing silver nanodendrites, including the following steps:

[0037] (1) Cleaning treatment of copper rods: The copper rods were cleaned with acetone, ethanol, 2mol / L dilute hydrochloric acid, and distilled water under ultrasonic conditions;

[0038] (2) Preparation of silver nanodendrites: Dissolve 0.85 g of silver nitrate in 100 mL of distilled water at room temperature, stir to fully dissolve the monovalent silver salt, and prepare a 0.05 mol / L silver nitrate solution; clean it well The cross-sectional area is 2.5 mm 2 , A copper rod with a length of 4cm is placed in a 5mL test tube, and 1mL of 0.05mol / L silver nitrate solution is dropped into the test tube with a dropper with a plastic tip, and reacted for 50s at room temperature; after the reaction is over, rinse the growth with distilled water The copper rod is dried naturally to obtain the target product.

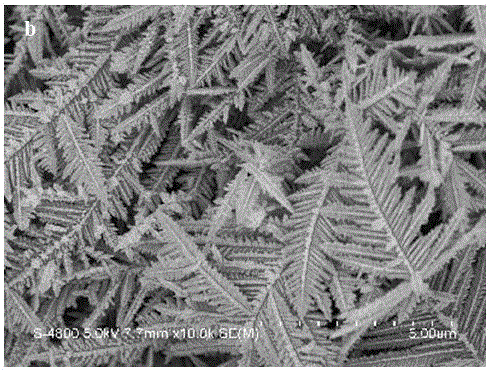

[0039] The target product obtained in this embodiment is silver nanode...

Embodiment 2

[0041] This embodiment relates to a method for preparing silver nanodendrites, including the following steps:

[0042] (1) Cleaning treatment of copper rods: The copper rods were cleaned with acetone, ethanol, 2mol / L dilute hydrochloric acid, and distilled water under ultrasonic conditions;

[0043] (2) Preparation of silver nanodendrites: Dissolve 0.17 g of silver nitrate in 100 mL of distilled water at room temperature, stir to fully dissolve the monovalent silver salt, and prepare a 0.01 mol / L silver nitrate solution; clean it well The cross-sectional area is 2.5 mm 2 , Put a 4cm copper rod into a 5mL test tube, take 1mL of 0.01mol / L silver nitrate solution and drop it into the test tube with a dropper with a plastic tip, and react for 50s at room temperature; after the reaction is over, rinse the growing black substance with distilled water The copper rod is dried naturally to obtain silver nano-dendrites.

Embodiment 3

[0045] This embodiment relates to a method for preparing silver nanodendrites, including the following steps:

[0046] (1) Cleaning treatment of copper rods: The copper rods were cleaned with acetone, ethanol, 2mol / L dilute hydrochloric acid, and distilled water under ultrasonic conditions;

[0047] (2) Preparation of silver nanodendrites: Dissolve 0.17 g of silver nitrate in 100 mL of distilled water at room temperature, stir to fully dissolve the monovalent silver salt, and prepare a 0.01 mol / L silver nitrate solution; clean it well The cross-sectional area is 2.5 mm 2 , A copper rod with a length of 4cm is placed in a 5mL test tube, and 1mL of 0.01mol / L silver nitrate solution is dropped into the test tube with a dropper with a plastic tip, and reacts for 120s at room temperature; after the reaction is over, rinse the growth of black substances with distilled water The copper rod is dried naturally to obtain silver nano-dendrites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com