Pin shooting platform device for accurately measuring thickness of continuous cast billet solidified shell and operating method thereof

A platform device and continuous casting slab technology, which is applied in the field of metallurgy, can solve the problems of inflexible adjustment of the nail gun, inaccurate measurement of the solidification thickness of the slab, and unfavorable practical operation, etc., so as to improve product quality, stabilize the nailing support, overcoming unsteady effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention.

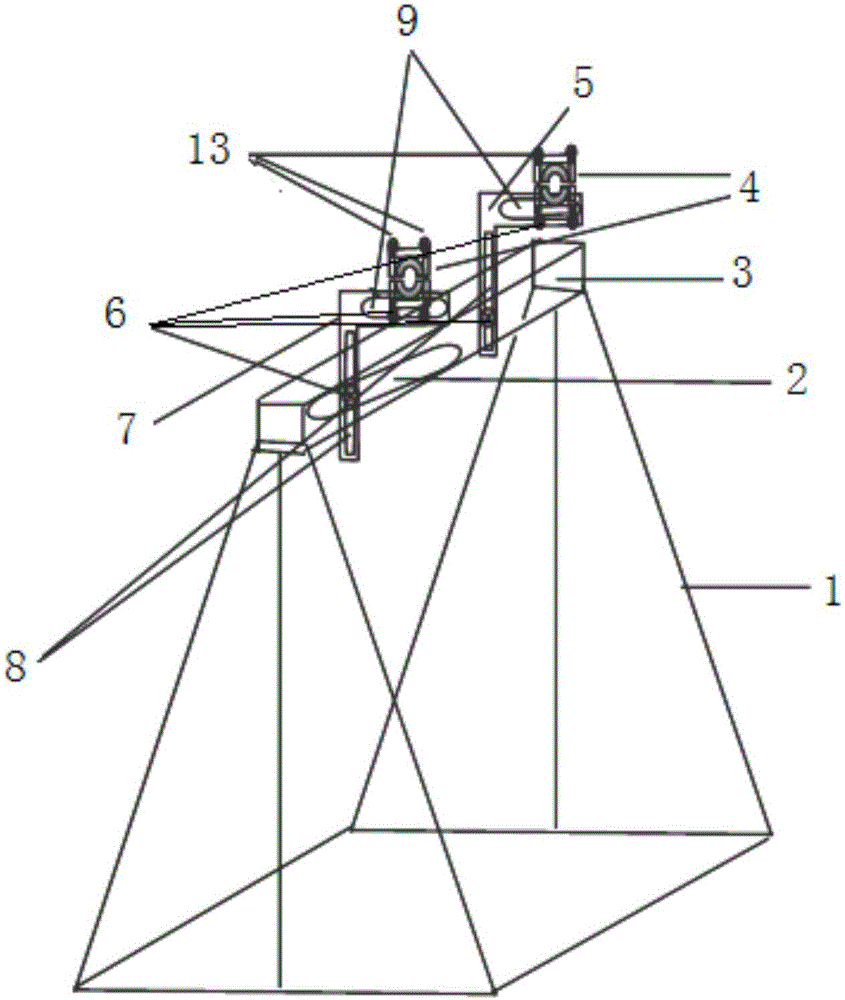

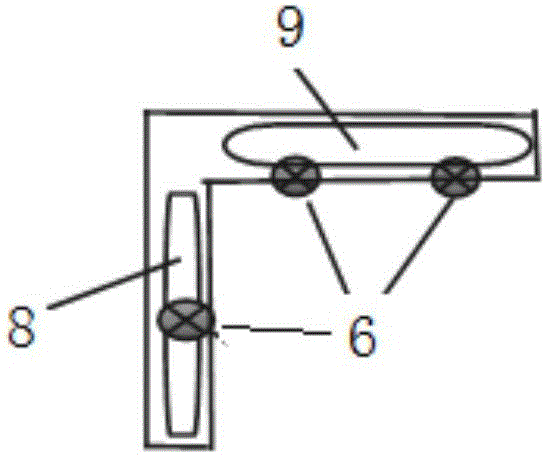

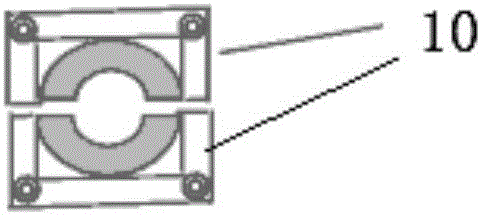

[0028] Such as Figure 1 to Figure 4 As shown, the invention provides a nailing platform device for accurately measuring the thickness of the solidified shell of the continuous casting slab. In the process of continuous casting and pouring in the steelmaking workshop, the nail shooting method is used to measure the solidified thickness of the slab, which has the characteristics of flexible adjustment and stable support. Use the nail gun 10 erected by this nail shooting platform device to shoot nails at various points of the billet after the second cooling section during the pouring process. The nails are stable during the shooting process, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com