Lifting frame for fast adjustment of to-be-tested area of detonation schlieren

A technology of the area to be tested and the lifting frame, which is applied in the field of lifting frames, can solve the problems of limited height adjustment range, uncertain adjustment range, and increased experimental cost, and achieve the effects of convenient operation, wide adaptability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and the specific implementation process.

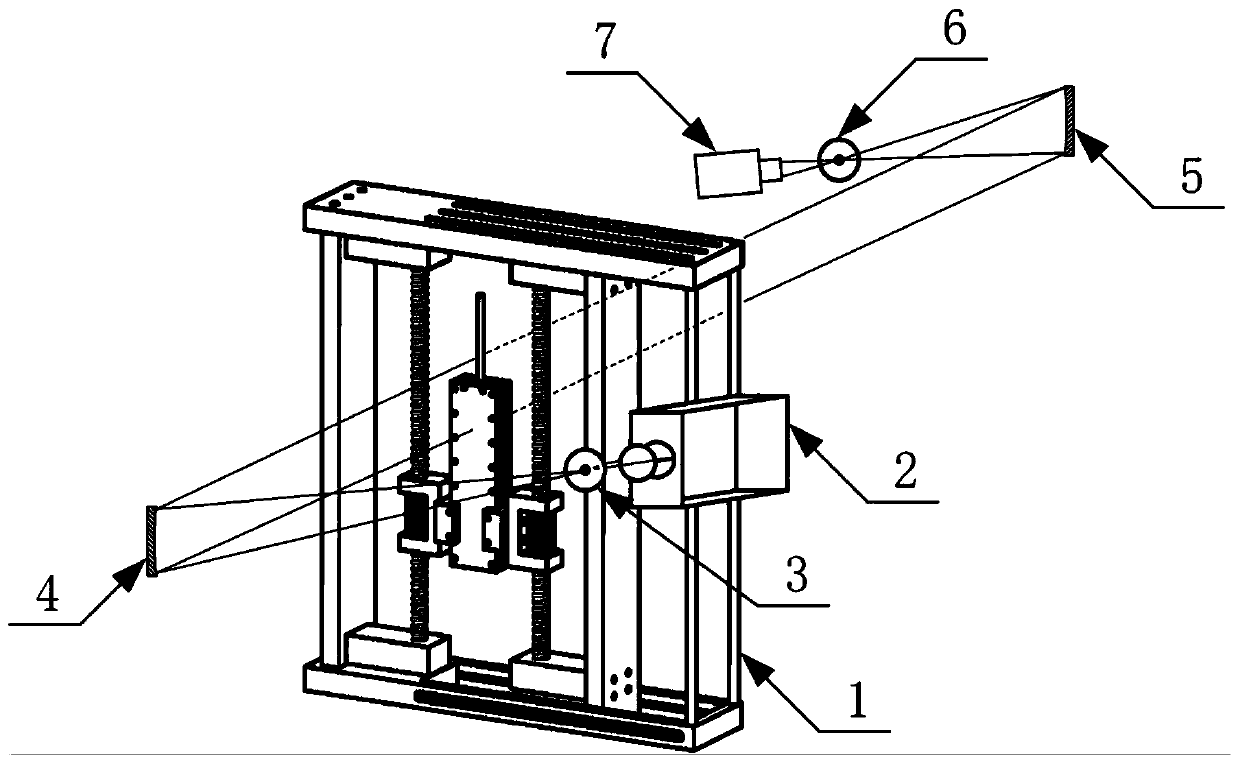

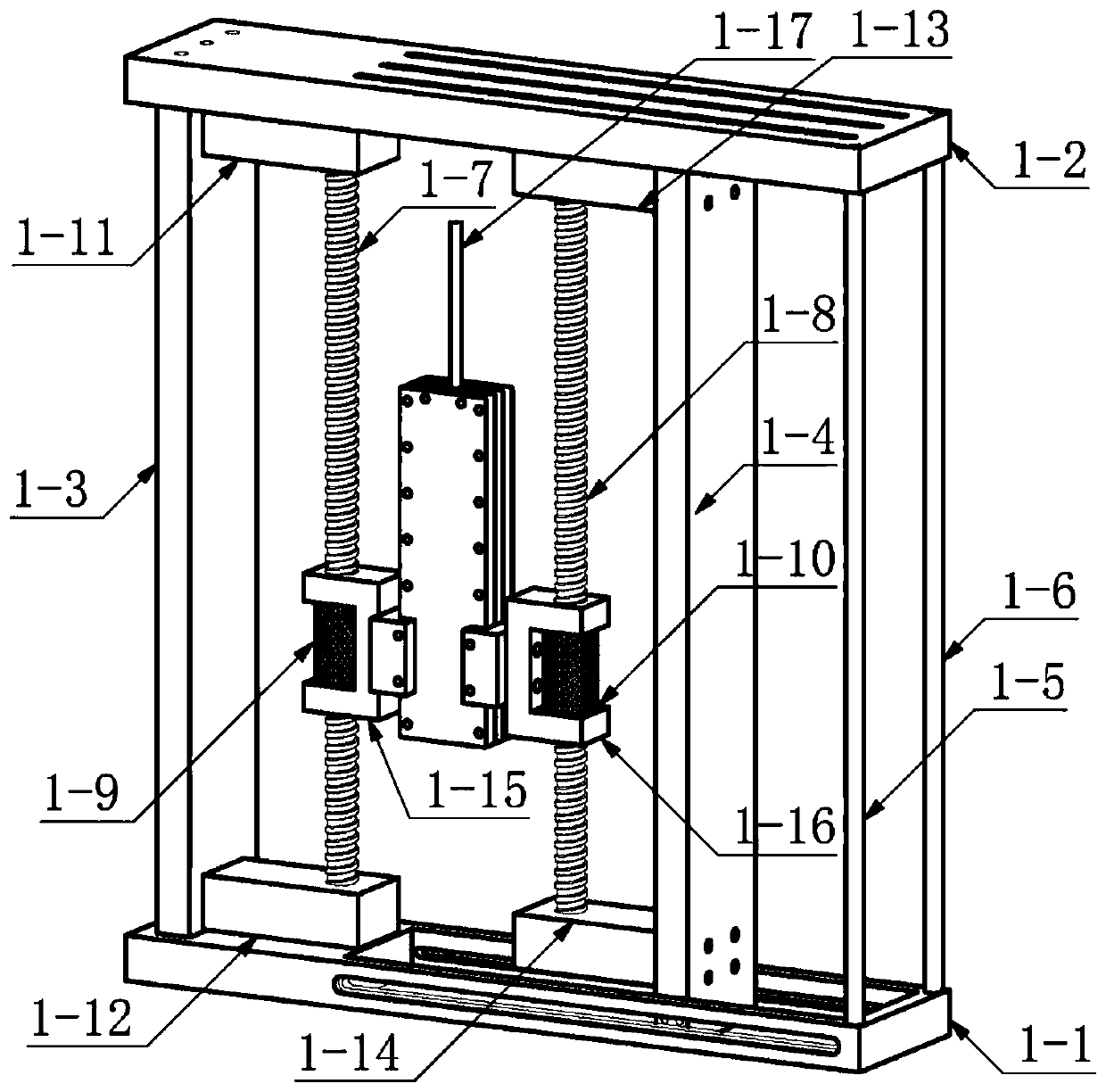

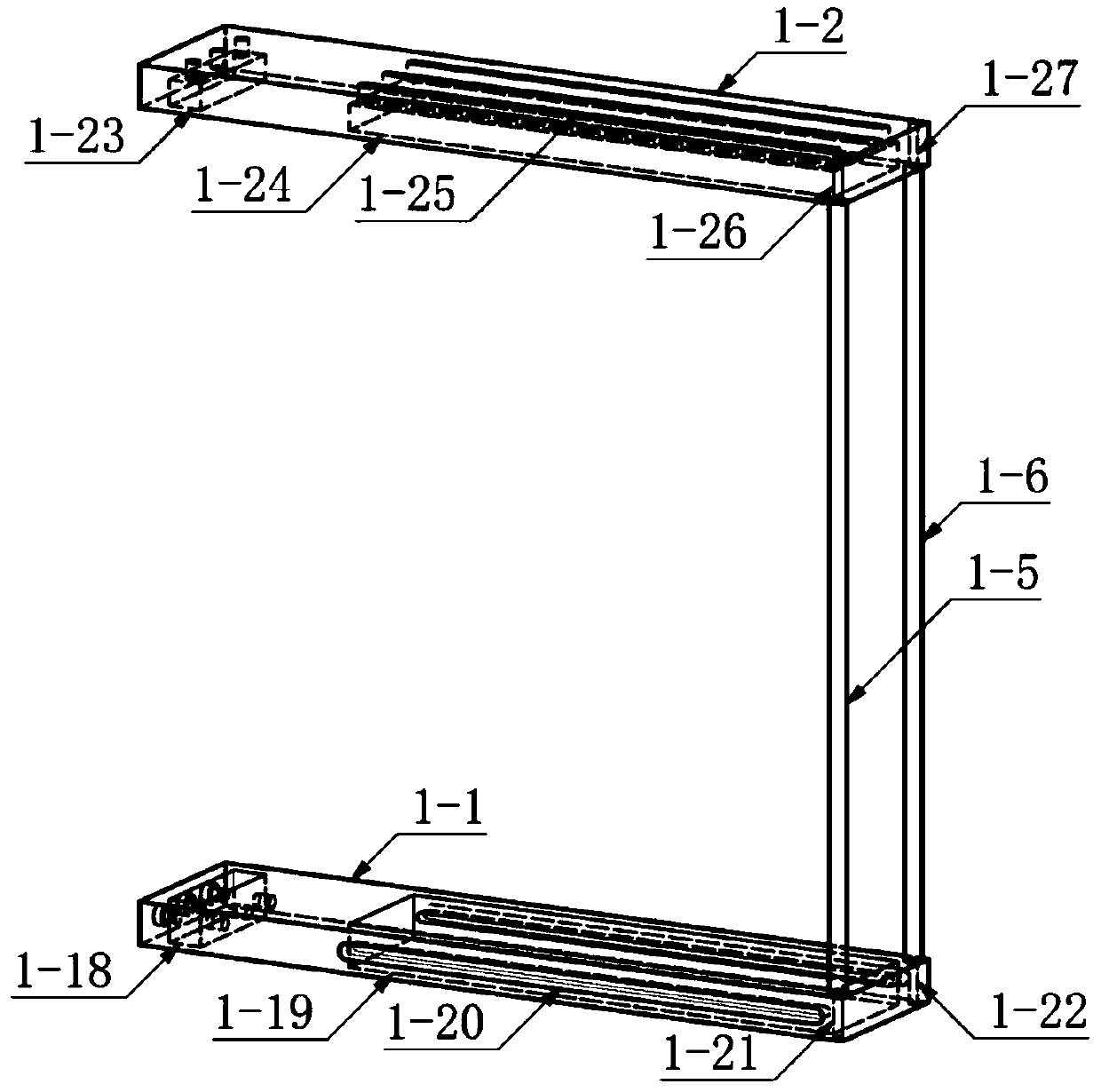

[0021] see figure 1 , before carrying out the schlieren measurement, first adjust the centers of the light source 2, the small hole 3, the first concave mirror 4, the second concave mirror 5, the knife edge 6, the high-speed camera 7 and other components to the same height to ensure that the first concave mirror 4 The reflected parallel light can just be completely projected onto the second concave mirror 5, and the angle between the light between the small hole 3 and the first concave mirror 4 and the light between the first concave mirror 4 and the second concave mirror 5 Keep within a small range of 10-20° to improve the shooting effect of schlieren images. The detonation chamber 1-17 (clamped by the lifting frame 1) is placed in the parallel light between the first concave mirror 4 and the second concave mirror 5 In this way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com