A fast adjustable pressing device

A pressing device and fast technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of poor pressing effect, complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

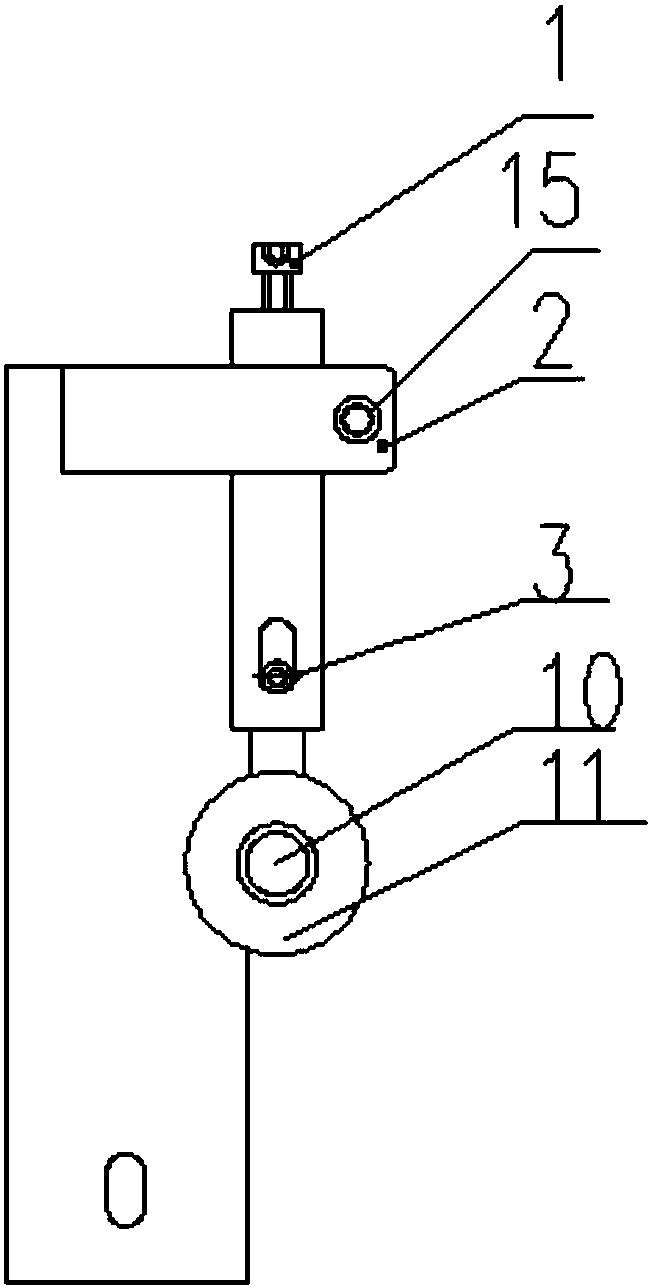

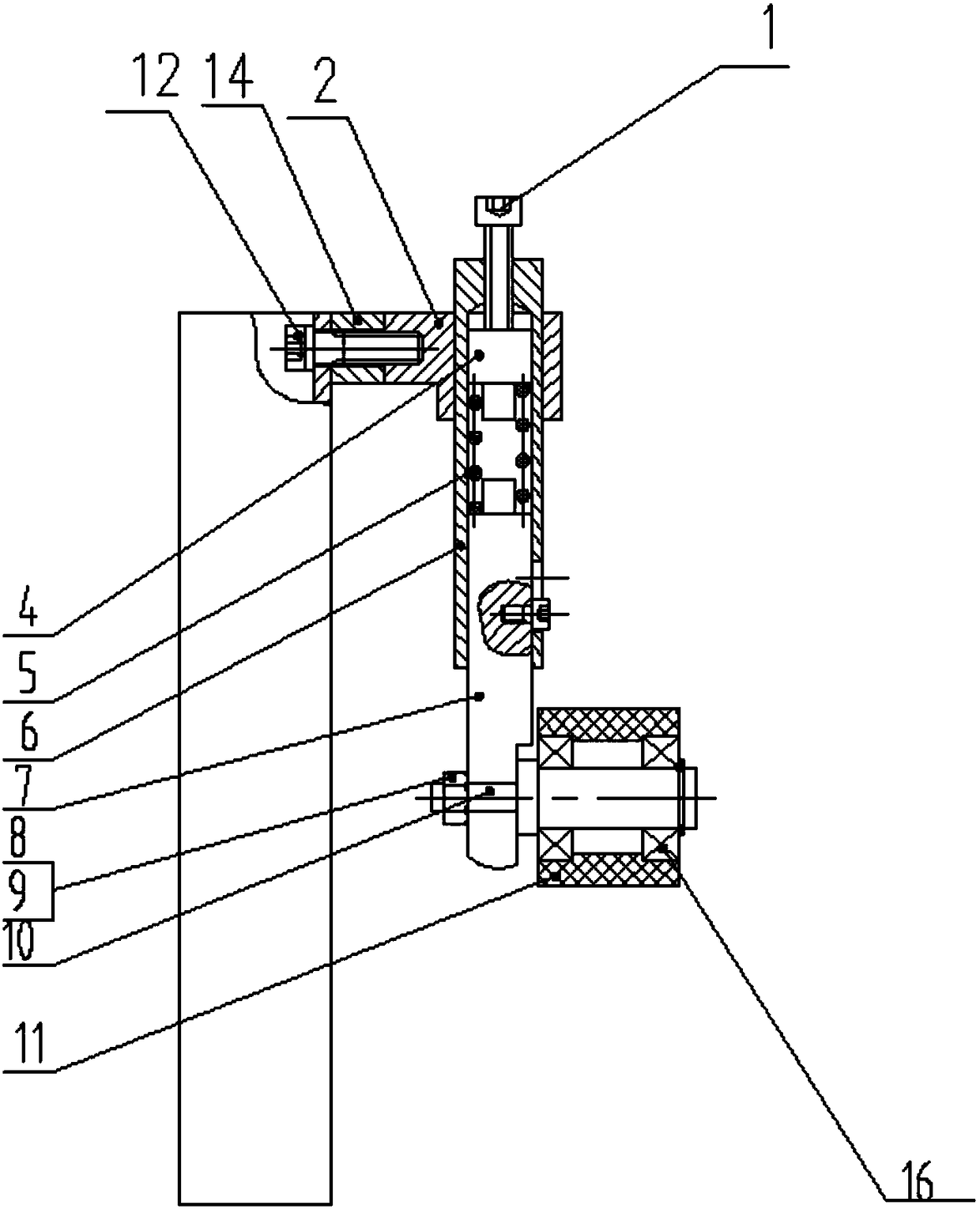

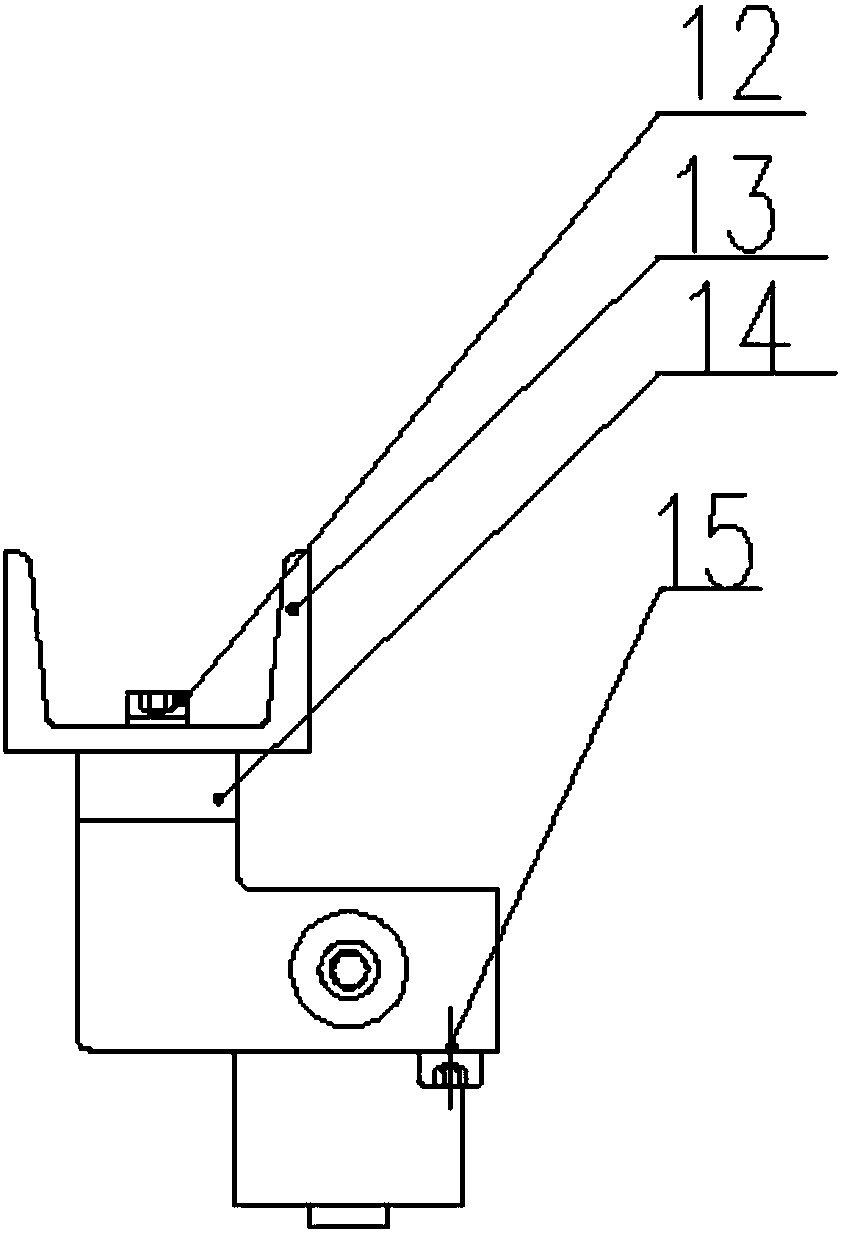

[0017] As shown in the figure, a fast adjustable pressing device includes a column 13, and an adjustment block 14 and a connecting seat 2 are sequentially arranged in the horizontal direction on the upper part of the column 13, wherein the horizontal section of the column 13 is a U-shaped structure, and the bottom surface of the U-shaped structure is The mounting surface of the column 13 is provided with a fixing hole on the top of the mounting surface, and the adjustment block 14 has a through hole, and the hexagon socket head screw 12 is used to pass through the fixing hole on the column 13, and the through hole 14 on the adjustment block is fixed on the connection seat 2 .

[0018] The connecting seat 2 has a telescopic sleeve hole formed therein, the inner diameter of which is slightly larger than the outer diameter of the telescopic sleeve 6, and the telescopic sleeve is compressed by fixing screws.

[0019] The telescopic sleeve 6 is provided with an adjustment shaft 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com