Oxidation-absorption supergravity desulfurization and denitrification system and method

A desulfurization, denitrification, and supergravity technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve the effects of simple structure, increased gas-liquid contact interface, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

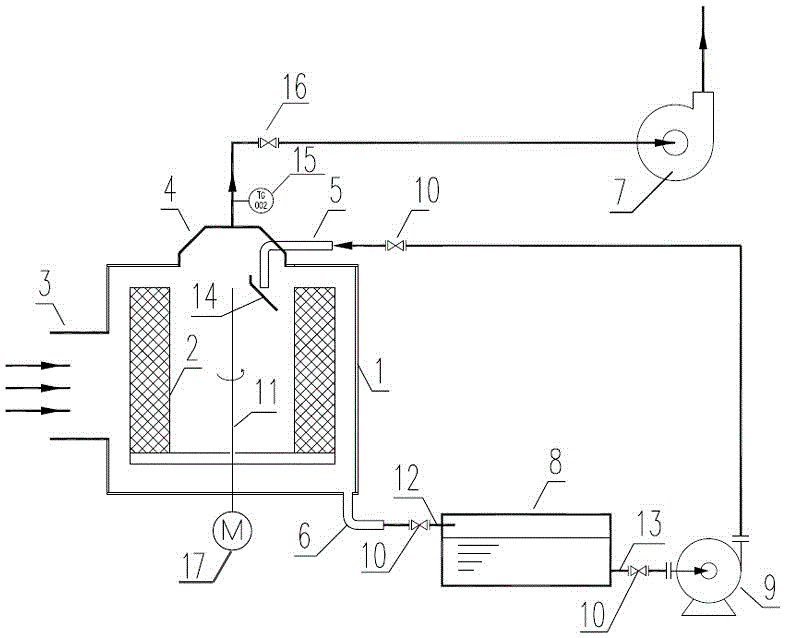

[0034] An oxidation-absorption supergravity desulfurization and denitrification system, its structure is as follows figure 1 As shown, it consists of a drug delivery device and a supergravity reactor. The drug delivery device includes a drug pool 8. The drug solution outlet 13 of the drug pool is connected to the inlet of the drug dosing pump 9. The imported medicine is connected to the entrance, and the medicine inlet is provided with a medicine inlet pipe 5; the supergravity reactor includes a shell 1, and an annular filler rotor 2 is arranged inside the shell, and the shell 1 is provided with a gas inlet 3 and a gas outlet 4 1. Medicine inlet and medicine outlet, the gas outlet 4 is connected with the induced draft fan 7, and the medicine outlet is provided with a medicine outlet pipe 6, which is connected with the return port 12 of the medicine pool 8.

[0035] The dimensions of the hypergravity reactor are: 0.9m in diameter and 1.0m in height.

[0036] On the pipeline wh...

Embodiment 2

[0048] The oxidation-absorption supergravity desulfurization and denitrification system of this embodiment is the same as that of Embodiment 1, the difference is that the size of the supergravity reactor is: 1.8m in diameter, 2.0m in height, the size of the baffle 14 is 100mm×100mm, and the packing rotor Ring diameter = 1.5~1.6m, inner ring diameter 1.3~1.4m.

[0049] Using the above system, the oxidation-absorption supergravity desulfurization and denitrification method is carried out on the mixed flue gas of a metallurgical enterprise in Anshan. The process steps include:

[0050] (1) Potassium monopersulfate is used as the oxidation absorbent, and a solution with a mass concentration of 6‰ is prepared in the liquid medicine pool;

[0051] (2) Control the flow rate of the liquid regulating valve to 4m / s, continuously introduce potassium monopersulfate solution into the packing of the annular packing rotor of the supergravity reactor, and turn on the induced draft fan to intr...

Embodiment 3

[0055] The oxidation-absorption supergravity desulfurization and denitrification system of this embodiment is the same as that of Embodiment 1, the difference is that the size of the supergravity reactor is: 2.4m in diameter, 2.6m in height, the size of the baffle plate 14 is 120mm×120mm, and the packing rotor Ring diameter = 2.0m, inner ring diameter 1.75m.

[0056] Using the above system, the oxidation-absorption supergravity desulfurization and denitrification method is carried out on the mixed flue gas of a chemical enterprise in Shenyang. The process steps include:

[0057] (1) Potassium monopersulfate is used as the oxidation absorbent, and a solution with a mass concentration of 6‰ is prepared in the liquid medicine pool;

[0058] (2) Control the flow rate of the liquid regulating valve to 5m / s, continuously introduce potassium monopersulfate solution into the packing of the annular packing rotor of the supergravity reactor, and turn on the induced draft fan to introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com