Preparation process of instant bamboo shoot product and product of preparation process

A preparation process and product technology, applied in the field of instant bamboo shoot product preparation process and its products, can solve the problems of long sterilization interval time affecting continuity, product brittleness, long sterilization time, etc., to achieve tender and delicious products, avoid Decreased taste and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

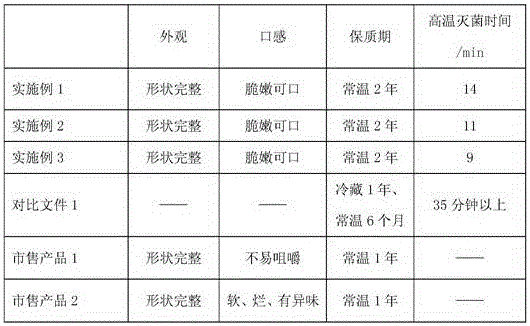

Examples

Embodiment 1

[0022] A kind of instant bamboo shoot product preparation technology, it comprises the following steps:

[0023] 1) Pretreatment: kill the fresh bamboo shoots until they have no biological activity, then shell them, slice them, cook them and cool them down;

[0024] 2) Sauce liquid preparation: prepare the sauce liquid with water, soy sauce, sugar and sodium glutamate, the weight ratio of water, soy sauce, sugar and sodium glutamate is 40:33:1.3:1.3;

[0025] 3) Packaging: Put the sauce and bamboo shoots into the container and seal it;

[0026] 4) High temperature sterilization: Put the sealed container into the sterilizer, control the temperature of the sterilizer to rise to 118°C within 6 minutes, and sterilize at 118°C for 8 minutes;

[0027] 5) Cooling and fusion: after ultra-high temperature sterilization, it is gradually cooled in three stages. First, add water to cool to 98°C, and then wait for 2 minutes. When the temperature inside and outside the sealed container is ...

Embodiment 2

[0029] A kind of instant bamboo shoot product preparation technology, it comprises the following steps:

[0030] 1) Pretreatment: kill the fresh bamboo shoots until they have no biological activity, then shell them, slice them, cook them and cool them down;

[0031] 2) Sauce preparation: use water, soy sauce, white sugar and sodium glutamate to prepare sauce liquid, the weight ratio of water, soy sauce, white sugar and sodium glutamate is 42:29:1:1.5;

[0032] 3) Packaging: Put the sauce and bamboo shoots into the container and seal it;

[0033] 4) High temperature sterilization: Put the sealed container into the sterilizer, control the temperature of the sterilizer to rise to 120°C within 4 minutes, and sterilize at 120°C for 7 minutes;

[0034] 5) Cooling and fusion: After high temperature sterilization, it is gradually cooled in three stages. First, add water to cool to 95°C, and then wait for 5 minutes. When the temperature inside and outside the sealed container is consi...

Embodiment 3

[0036] A kind of instant bamboo shoot product preparation technology, it comprises the following steps:

[0037] 1) Pretreatment: kill the fresh bamboo shoots until they have no biological activity, then shell them, slice them, cook them and cool them down;

[0038] 2) Sauce preparation: use water, soy sauce, white sugar and sodium glutamate to prepare the sauce, and the weight ratio of the water, soy sauce, white sugar and chicken essence is 45:33:1.3:1.2;

[0039] 3) Packaging: Put the sauce and bamboo shoots into the container and seal it;

[0040] 4) High temperature sterilization: Put the sealed container into the sterilizer, control the temperature of the sterilizer to rise to 125°C within 5 minutes, and sterilize at 125°C for 4 minutes;

[0041] 5) Cooling fusion: After high temperature sterilization, it is gradually cooled in three stages. First, add water to cool to 100°C, and then wait for 3 minutes. When the temperature inside and outside the sealed container is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com