Blade root for a turbine blade

A technology of turbine blades and turbine blades, which is applied to the supporting elements of blades, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc. problems, to achieve the effect of short start-up time, fast load change, and minimization of the tendency of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

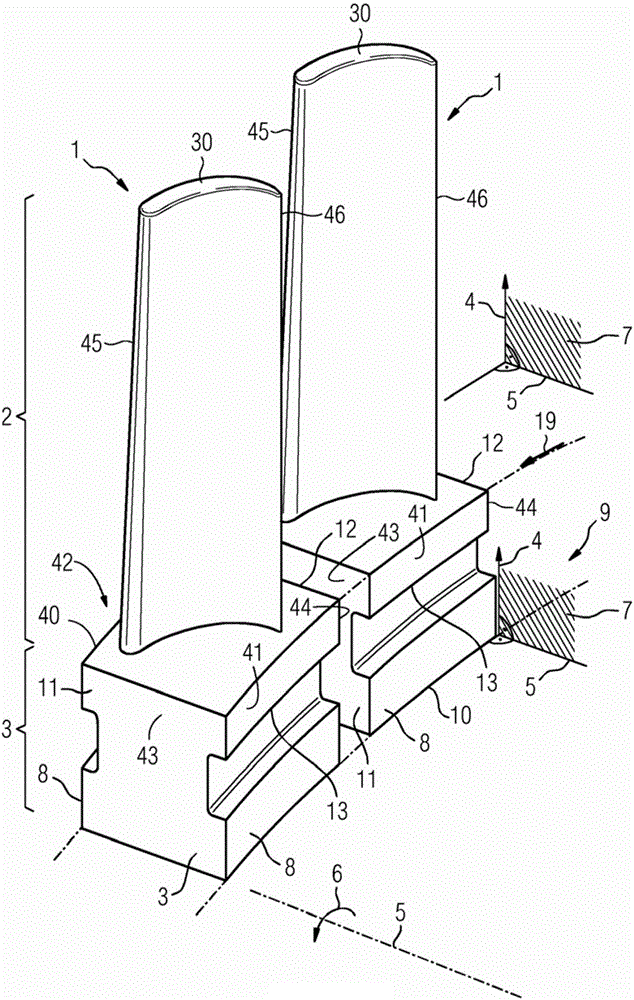

[0032] figure 1 A turbine blade 1 is shown. The turbine blade 1 can be a turbine guide blade or a turbine rotor blade. The turbine blade 1 has an airfoil 2 and a blade root 3 which are arranged along a blade axis 4 . The blade axis 4 corresponds substantially to the elongated configuration of the turbine blade 1 . The blade airfoil 2 is shaped and designed for installation in a fluid machine, in particular a steam turbine. The turbine blade 1 engages in a groove which is not shown in detail. A fluid machine, such as a steam turbine, has a rotor mounted rotatably about an axis of rotation 5 and a housing arranged around the rotor. The grooves are provided on the surface (not shown) in the rotor, the rotor being formed around the axis of rotation 5 . As a result, the rotor rotates in a direction of rotation 6 about the axis of rotation 5 . The blade axis 4 is here formed perpendicular to the axis of rotation 5 . The axis of rotation 5 and the blade axis 4 form a radius su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com