Cable processing apparatus and method for removing a screening film from a screened multi-core round cable

A technology for processing devices and cables, which is used in cable installation devices, cable installation, and equipment for dismantling/armored cables, etc. It can solve the problems of damaged cable end insulation protection, low efficiency, and troublesome removal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

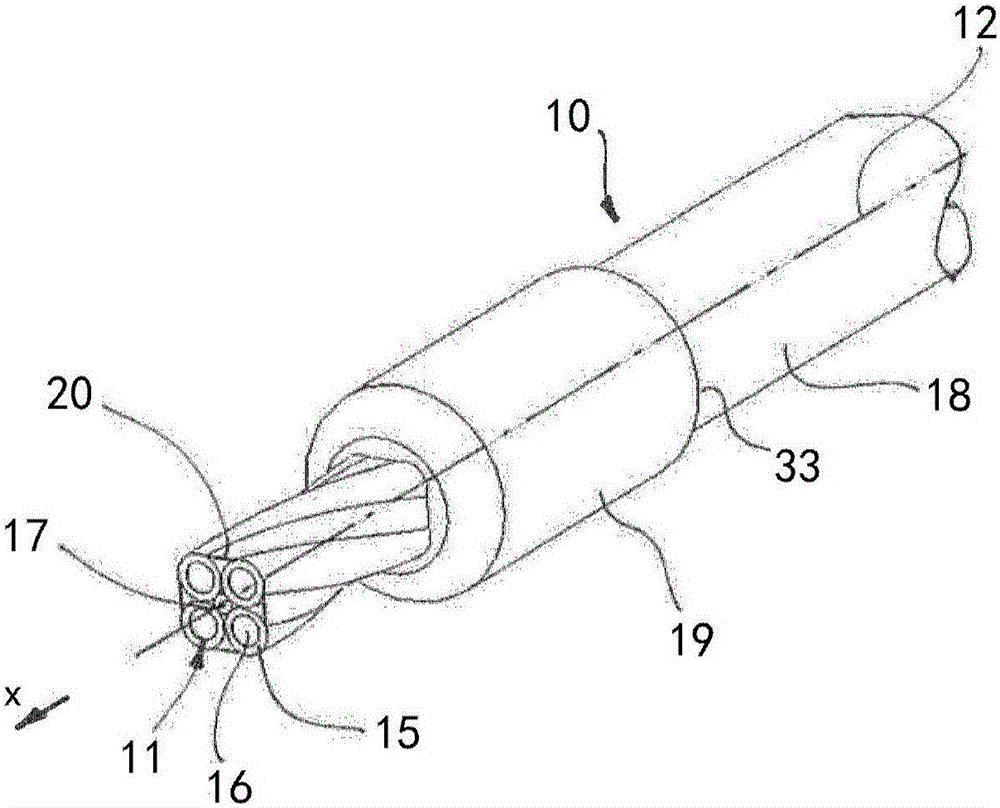

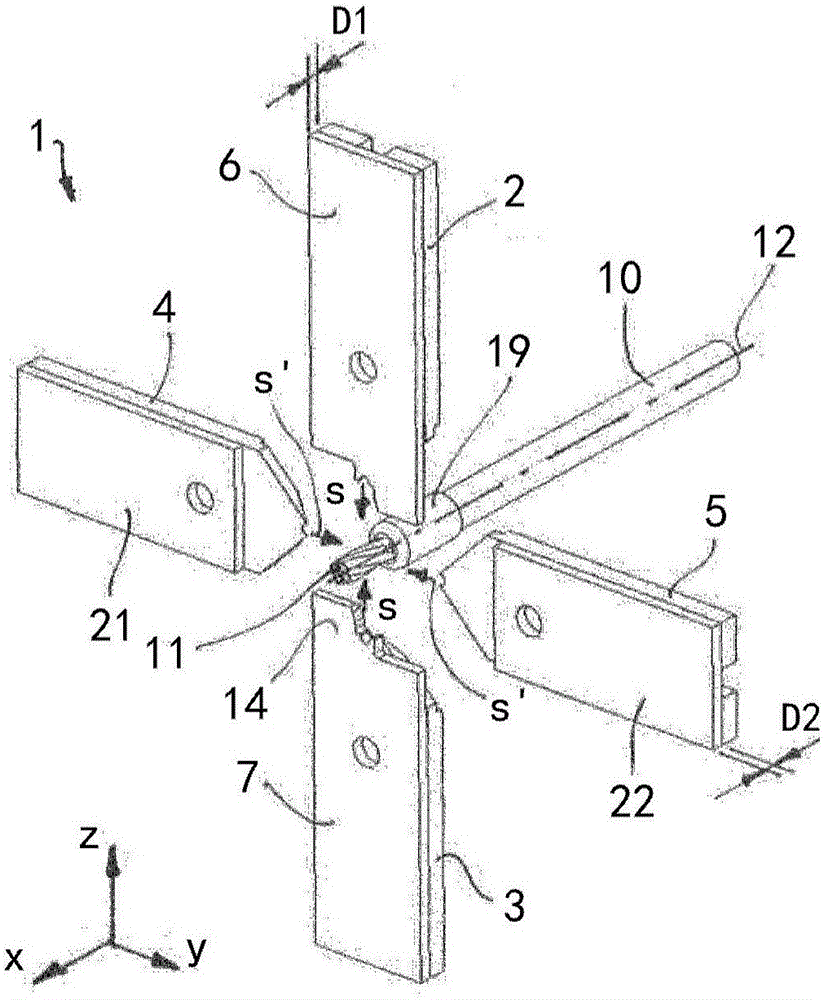

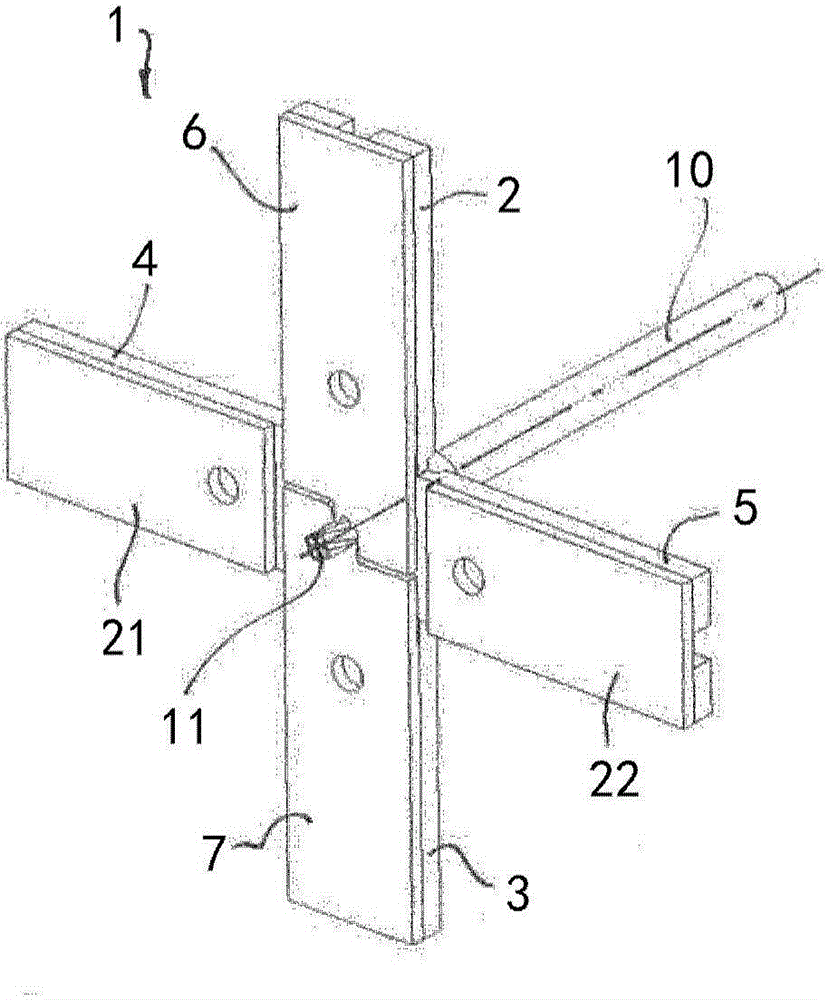

[0036] figure 1 The cable end of the shielded four-core round cable 10 is shown. The four cores of the shielded round cable 10 are denoted by 11, wherein each core has a conductor 16 and an insulating portion 15 covering the conductor. The conductor 16 is generally a core wire or wire made of a conductive metal material such as copper or aluminum. The cable ends 11 are bundled in a circular shape and are twisted around a filler 17 made of insulating material that is circular in cross section. The filler 17 may also be composed of textile fibers. Additionally, the round cable 10 may have a metal wire in the center. The round cable 10 is externally protected by a sheathed insulating part 18 constructed of PVC or other electrically insulating elastic synthetic materials to prevent weather or other external influences. In order to achieve electrical shielding, the round cable 10 has a shielding metal wire 19 made of conductive material and a shielding film 20. The shielding fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com