Method for synthesizing graphene-nickel hydroxide composite supercapacitor electrode by using one-step hydrothermal method

A technology of supercapacitor and nickel hydroxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of low specific capacitance and no material capacitance performance, and achieve low cost and good electrochemical energy storage. Performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

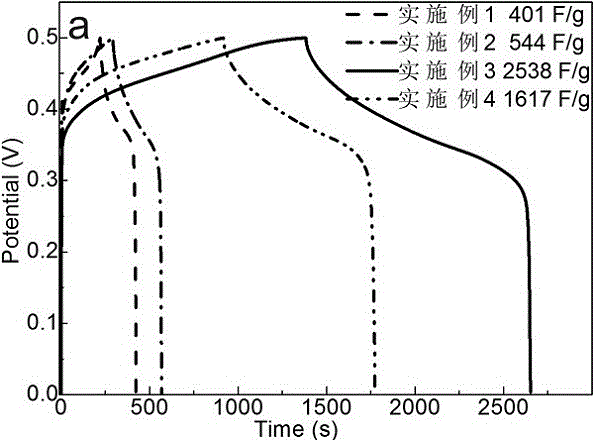

[0014] Dissolve 0.1g of P123 and 0.01g of graphene oxide (prepared by the Hummer method, the same as above) in 20mL of deionized water, ultrasonically disperse for 2 hours to form a uniform dispersion, and then add 0.5816g (2mmol) nickel nitrate hexahydrate and 0.12g (2mmol) urea was added to the above uniform dispersion, stirred for 1h to form a uniform precursor solution, then the above precursor solution was transferred to a 25mL hydrothermal reaction kettle, and the weighed foamed nickel substrate (10mm×10mm×1mm ) was immersed in the precursor solution in the hydrothermal reactor, and reacted hydrothermally at 100°C for 5 hours to grow and deposit graphene-nickel hydroxide composite on the nickel foam substrate. After the reaction was completed, the nickel foam was taken out and placed in deionized water for ultrasonication. Wash until the washing solution is colorless, and then dry to obtain a graphene-nickel hydroxide composite active electrode.

[0015] The prepared act...

Embodiment 2

[0017] Dissolve 0.1g P123 and 0.01g graphene oxide in 20mL deionized water, ultrasonically disperse for 2 hours to form a uniform dispersion, then add 1.1632g (4mmol) nickel nitrate hexahydrate and 0.24g (4mmol) urea to the above uniform dispersion , stirred for 1 h to form a uniform precursor solution, then transferred the above precursor solution to a 25mL hydrothermal reactor, and immersed the weighed foam nickel substrate (10mm×10mm×1mm) in the precursor solution in the hydrothermal reactor In the body solution, hydrothermal reaction at 180 °C for 2 hours, the graphene-nickel hydroxide composite was grown and deposited on the foamed nickel substrate. After the reaction was completed, the foamed nickel was taken out and placed in deionized water for ultrasonic cleaning until the washing liquid was colorless, and then dried A graphene-nickel hydroxide composite active electrode is obtained.

[0018] With the prepared active electrode as the working electrode, the electrochem...

Embodiment 3

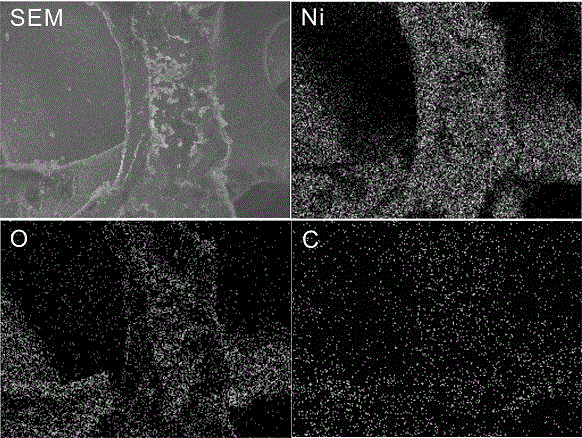

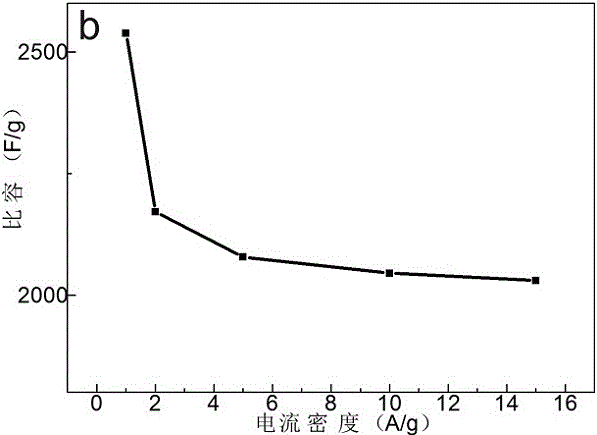

[0020] Dissolve 0.1g P123 and 0.01g graphene oxide in 20mL deionized water, ultrasonically disperse for 2 hours to form a uniform dispersion, then add 2.3264g (8mmol) nickel nitrate hexahydrate and 0.48g (8mmol) urea to the above uniform dispersion , stirred for 1 h to form a uniform precursor solution, then transferred the above precursor solution to a 25mL hydrothermal reactor, and immersed the weighed foam nickel substrate (10mm×10mm×1mm) in the precursor solution in the hydrothermal reactor In the body solution, hydrothermal reaction at 120 °C for 24 hours, the graphene-nickel hydroxide composite was grown and deposited on the foamed nickel substrate. After the reaction was completed, the foamed nickel was taken out and placed in deionized water for ultrasonic cleaning until the washing liquid was colorless, and then dried A graphene-nickel hydroxide composite active electrode is obtained. In this composite electrode, graphene-nickel hydroxide is uniformly deposited on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com