Silver nanowire transparent conductive thin film and preparation method thereof

A technology of transparent conductive films and silver nanowires, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem that the electrical connection of silver nanowires is not effective enough and affects The practical application of silver nanowire transparent conductive film, the uneven conductivity of the surface of silver nanowire film, etc., to achieve excellent optical transmission performance, increase conductive uniformity, and enhance the effect of effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

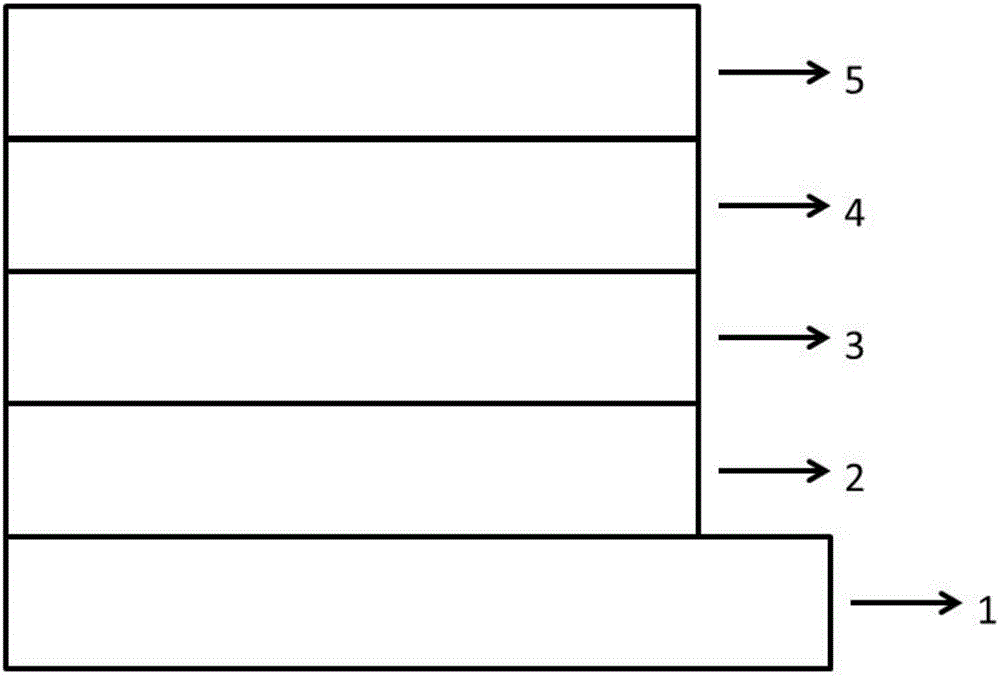

Method used

Image

Examples

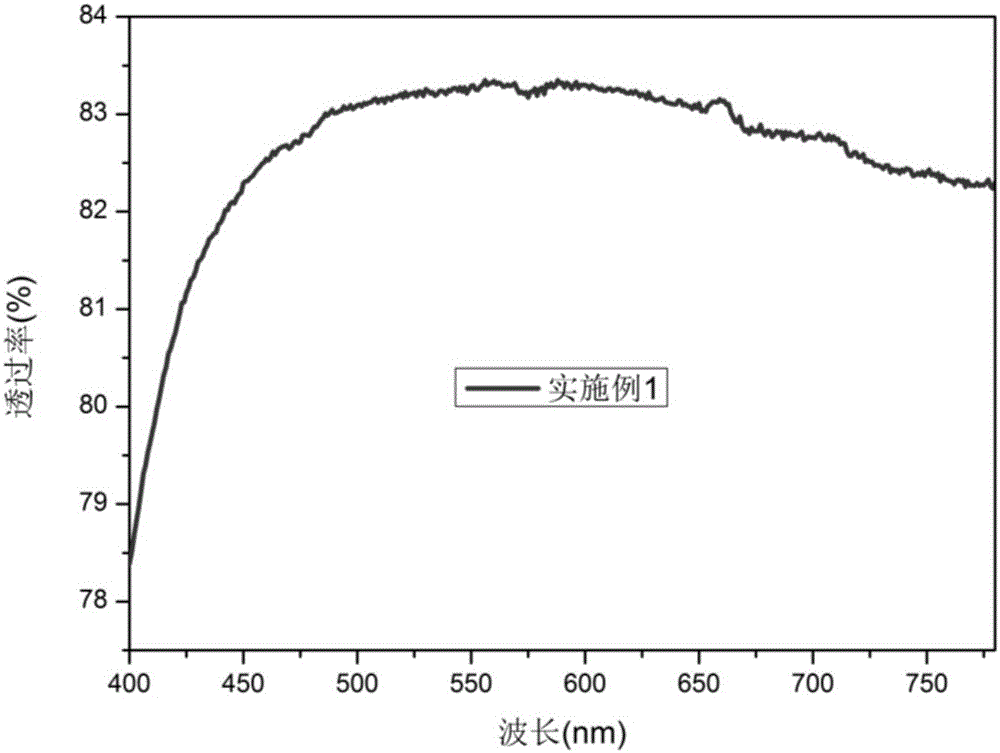

Embodiment 1

[0034] (1) Prepare a silver nanowire dispersion, the solvent of the silver nanowire dispersion is absolute ethanol, and the concentration of the silver nanowire in the solvent is 0.2-2mg / ml.

[0035] (2) Preparation of TiO x Sol: Magnetically stir anhydrous ethanol and diethanolamine in a 40°C water bath for 10 minutes, then add butyl titanate, magnetically stir in a 40°C water bath for 10 minutes, add deionized water, and magnetically stir in a 40°C water bath for 30 minutes to obtain light yellow liquid. The solution was filtered with medium-speed filter paper and then aged for 24h. Wherein the molar ratio of absolute ethanol:diethanolamine:butyl titanate:deionized water is (50-100):(2-5):(5-10):1.

[0036] (3) Cleaning the glass substrate: first, ultrasonically clean the substrate with deionized water for 10-20min, then ultrasonically clean with acetone for 10-20min, then ultrasonically treat with absolute ethanol for 10-20min, and finally ultrasonically treat with deioni...

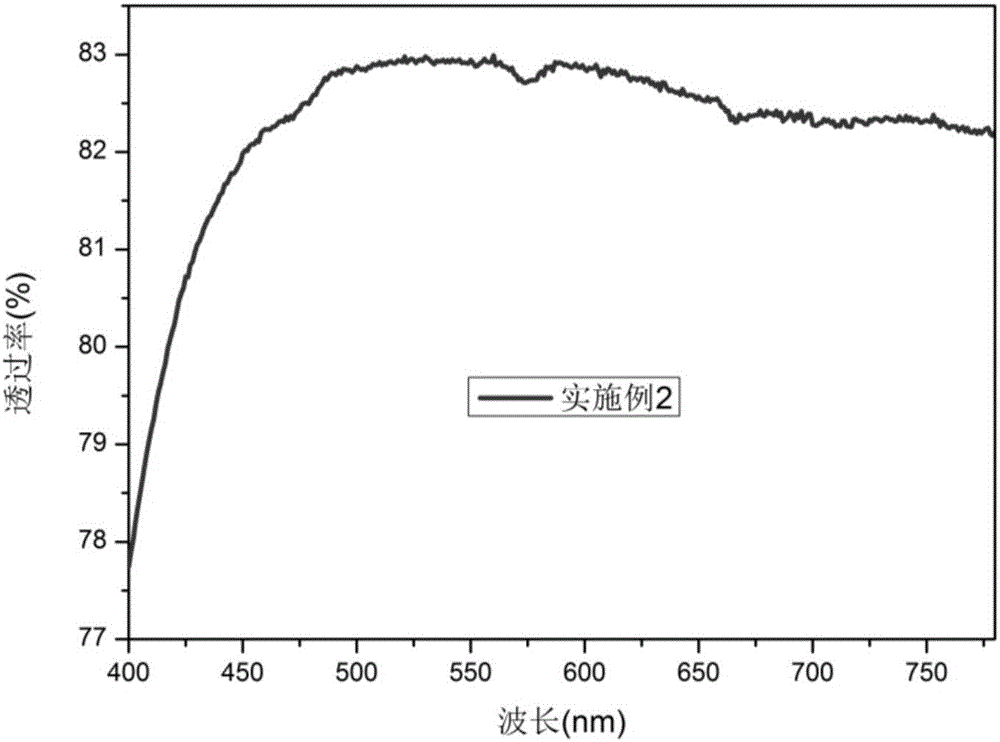

Embodiment 2

[0044] (1) Prepare a silver nanowire dispersion, the solvent of the silver nanowire dispersion is absolute ethanol, and the concentration of the silver nanowire in the solvent is 0.2-2mg / ml.

[0045] (2) Preparation of TiO x Sol: Magnetically stir anhydrous ethanol and diethanolamine in a 40°C water bath for 15 minutes, then add butyl titanate, magnetically stir in a 60°C water bath for 5 minutes, add deionized water, and magnetically stir in a 30°C water bath for 60 minutes to obtain light yellow liquid. Filter the solution with medium speed filter paper, then age for 30h. Wherein the molar ratio of absolute ethanol:diethanolamine:butyl titanate:deionized water is (50-100):(2-5):(5-10):1.

[0046] (3) Cleaning the glass substrate: first, ultrasonically clean the substrate with deionized water for 10-20min, then ultrasonically clean with acetone for 10-20min, then ultrasonically treat with absolute ethanol for 10-20min, and finally ultrasonically treat with deionized water for...

Embodiment 3

[0054] (1) Prepare a silver nanowire dispersion, the solvent of the silver nanowire dispersion is absolute ethanol, and the concentration of the silver nanowire in the solvent is 0.2-2mg / ml.

[0055] (2) Preparation of TiO x Sol: Magnetically stir anhydrous ethanol and diethanolamine in a 40°C water bath for 8 minutes, then add butyl titanate, magnetically stir in a 30°C water bath for 20 minutes, add deionized water, and magnetically stir in a 60°C water bath for 40 minutes to obtain light yellow liquid. The solution was filtered with medium-speed filter paper and then aged for 36h. Wherein the molar ratio of absolute ethanol:diethanolamine:butyl titanate:deionized water is (50-100):(2-5):(5-10):1.

[0056] (3) Cleaning the glass substrate: first, ultrasonically clean the substrate with deionized water for 10-20min, then ultrasonically clean with acetone for 10-20min, then ultrasonically treat with absolute ethanol for 10-20min, and finally ultrasonically treat with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com