Fuel cell system and fuel cell module thereof

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as poor contact of electrodes or other components, poor overall performance of fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

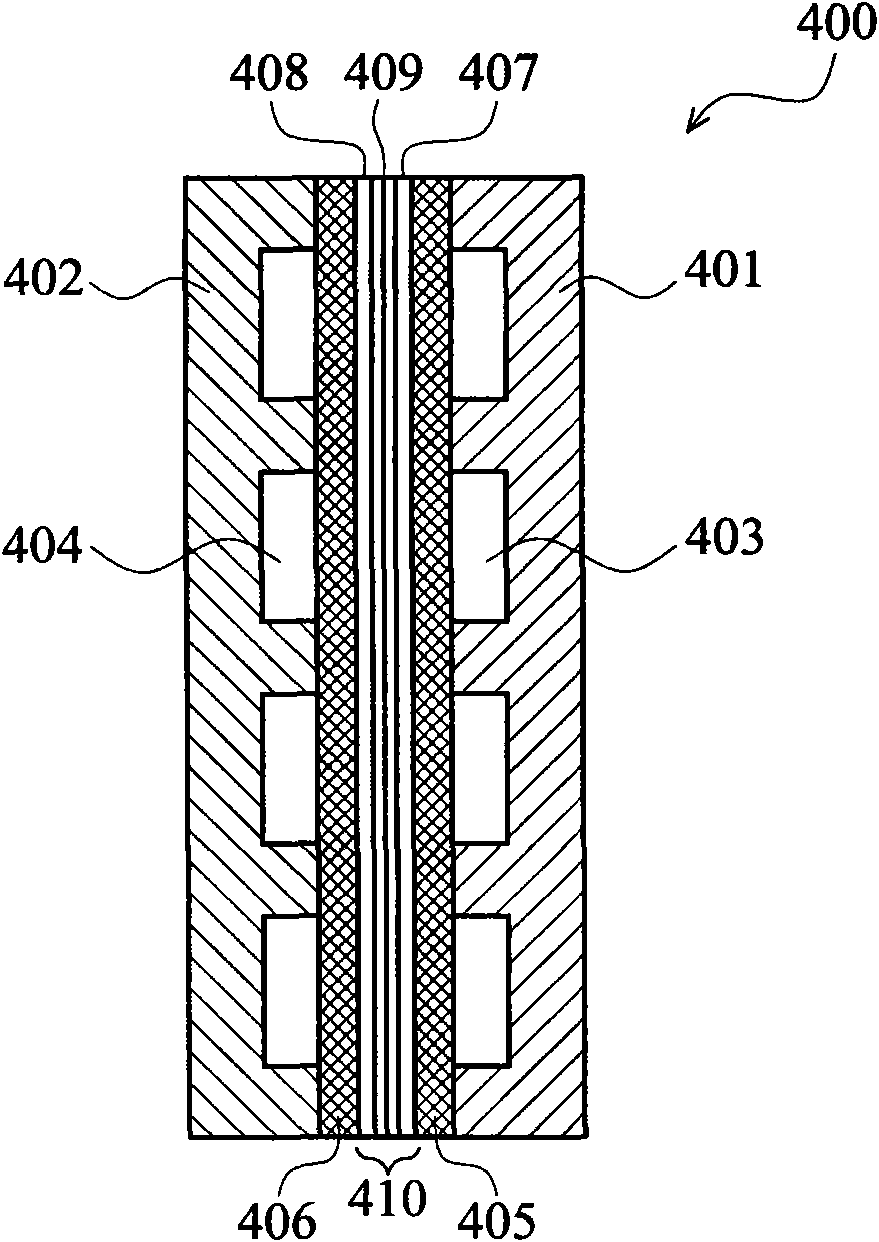

[0050] An embodiment of the present invention provides a fuel cell module, wherein non-planar structures are formed on one or more components inside the fuel cell module, so that a contact force can be generated during or after the fuel cell module is assembled. In one embodiment, an arc-shaped or polygonal structure protruding toward the membrane electrode group can be formed on the collector element or other elements. With the cooperation of system design, practical application or other factors, the aforementioned contact force can indeed strengthen the inter-element contact force. Conductivity, uniformity of conduction and / or reliability under long-term use.

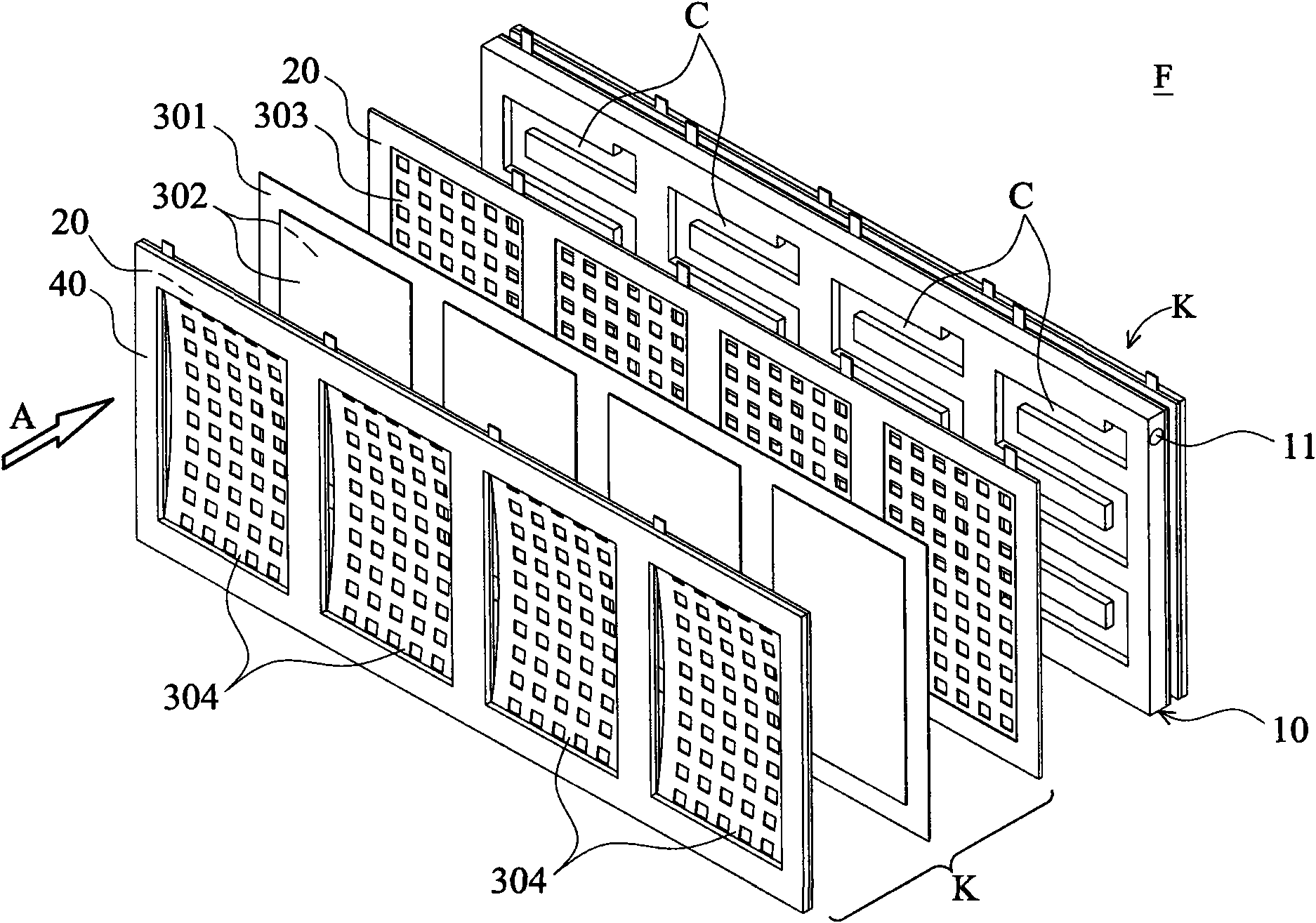

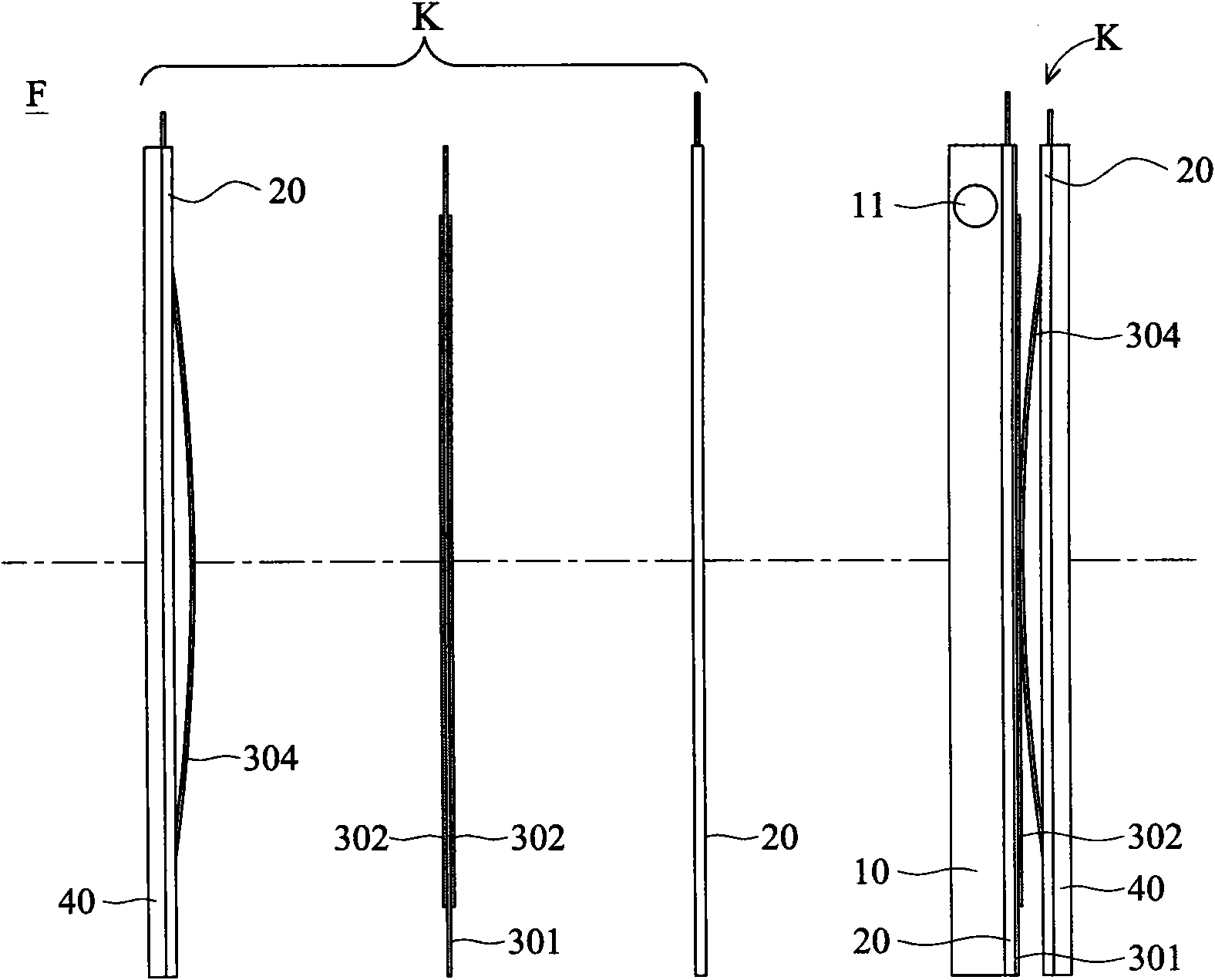

[0051] Figure 2A It is an exploded view of a fuel cell module according to an embodiment of the present invention. Figure 2B is a side view of a fuel cell module according to an embodiment of the present invention, consisting of Figure 2B The local structure of the fuel cell module before and after assembly can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com