Method for measuring scattering ratio of metal alloy material based on digital ray imaging technology detector response curve

A metal alloy and digital ray technology, applied in the field of material characterization, can solve the problems of environmentally harmful chemical waste liquid, long cycle time, and large film consumption, and achieve the effects of avoiding environmental hazards, improving efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

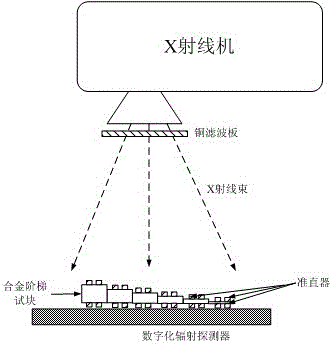

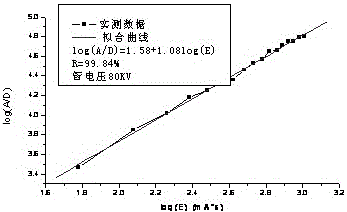

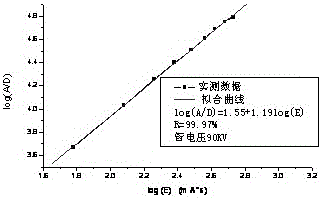

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0020] Now take the measurement of the scattering ratio of TC4 titanium alloy and GH4169 superalloy by the IP plate response curve of ray CR technology as an example to illustrate the measurement method of the present invention.

[0021] Step 1: Expose the IP board to different tube voltages. The tube voltage coverage range is selected according to the material and actual needs, up to the maximum rated tube voltage limit of the conventional X-ray machine, which is about 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com