Imaging sensor image plane parallelism debugging system and method based on microscopic measurement

An imaging sensor and microscopic measurement technology, which is used in measurement devices, optical instrument testing, and optical performance testing, etc., can solve problems such as unfavorable accurate calculation, poor debugging accuracy, and large debugging workload, so as to improve assembly and debugging efficiency and ensure Batch quality, easy debugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

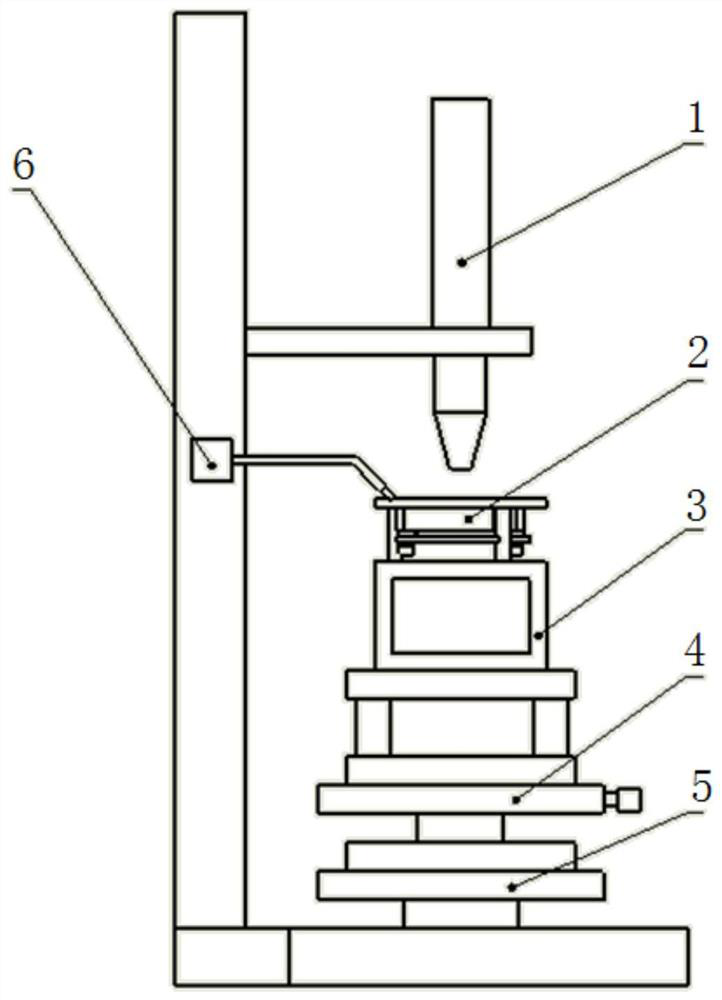

[0039] The measurement system used in the image plane parallelism debugging method based on microscopic measurement is as follows: figure 1 As shown, it includes an eccentricity instrument air bearing platform 5 , a four-dimensional adjustment table 4 , auxiliary tooling 3 , an eccentricity instrument imaging microscope 1 and a dial gauge 6 . The four-dimensional adjustment table 4 is set on the air-floating platform 5 of the eccentricity instrument, the auxiliary tooling 3 is set on the four-dimensional adjustment table 4 , and the sensor assembly 2 to be debugged is installed on the auxiliary tooling 3 . The eccentricity imaging microscope 1 and the dial gauge 6 are arranged on the support, and the eccentricity imaging microscope 1 is located directly above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com