Direct current electric arc furnace bottom electrode structure and application thereof

A technology of DC electric arc furnace and bottom electrode, which is applied in electric furnace, electric furnace heating, furnace and other directions, can solve the problems of inability to guarantee the normal operation of DC electric furnace, low service life of bottom electrode, fast electrode loss and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

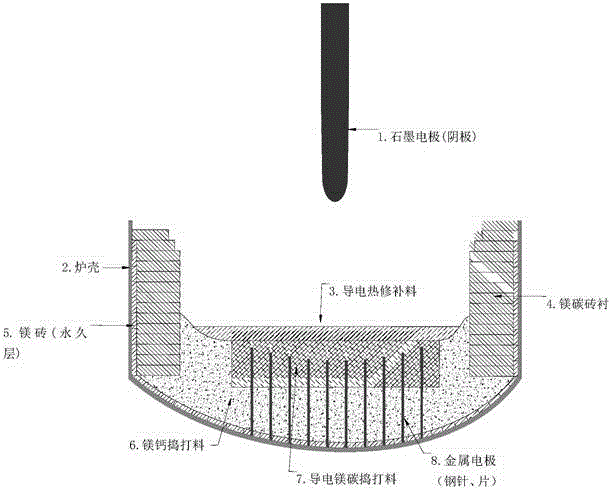

[0036]For a 10t needle-type DC arc furnace, after the metal anode steel needle is installed, ram the dry-type magnesium-calcium ramming material 6 with a thickness of 350mm. Special vibrating and ramming equipment should be used for ramming construction. Then add magnesia carbonaceous conductive ramming material 7 for construction, the overlapping thickness of magnesia carbonaceous conductive ramming material and steel needle is 300mm, and then ram the conductive magnesia carbonaceous ramming material 50mm thick above the steel needle. The ramming construction method is the same as that of dry magnesium-calcium ramming material. Be sure to hit the dense. This is important not only for corrosion resistance but also for electrical conductivity. Then build the magnesia-carbon brick furnace lining, and then ram the periphery and slope of the electric furnace with dry magnesia-calcium ramming material. In this way, steelmaking raw materials can be added and electricity can be su...

Embodiment 2

[0038] After the metal anode steel sheet is installed, dry-type magnesium-calcium ramming material 6 with a thickness of 400mm is rammed. It is worth pointing out that, in order to achieve densification, the thickness of each feeding should not be greater than 100mm, and special vibrating ramming equipment should be used for ramming. Hit construction. Then add magnesium carbonaceous conductive ramming material 7 for construction, the overlapping thickness of magnesium carbonaceous conductive ramming material and steel sheet is 200mm, and ramming magnesium carbonaceous ramming material 200mm thick on the steel sheet. The ramming construction method is the same as that of dry magnesium-calcium ramming material. Be sure to hit the dense. This is important not only for corrosion resistance but also for electrical conductivity. Then build the magnesia-carbon brick furnace lining, and then ram the periphery and slope of the electric furnace with dry magnesia-calcium ramming materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com