Car drum test soundproof room

A drum test, soundproof room technology, applied in the direction of sound insulation, insulation layer, special buildings, etc., can solve the problems of large noise, pollution, etc., to achieve the effect of reducing noise pollution, weakening sound wave energy, and excellent sound absorption and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

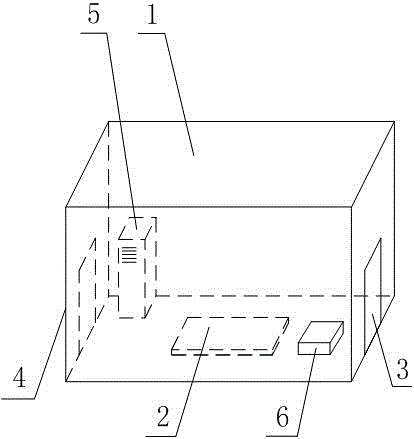

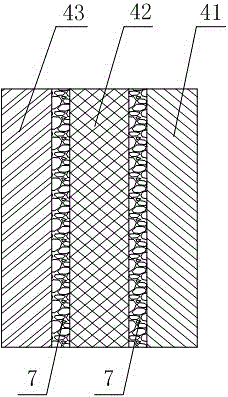

[0020] like figure 1 and figure 2 A car drum test sound insulation room shown, wherein figure 1 中虚线表示视线被遮挡部分,包括内部设置有转鼓试验台2的工作室1,工作室1的相对两侧面分别设置有室门3,室门3的门板采用PVB夹层玻璃制作而成;工作 室1的墙体为隔音墙4,隔音墙4包括由内向外依次设置的珍珠岩吸音板41、真空玻璃层42、水泥木屑吸声板43;所述珍珠岩吸音板41与真空玻璃层42 之间充填玻璃棉7,所述真空玻璃层42与水泥木屑吸声板43之间充填玻璃棉7;工作室1内还设置有温度调节装置5;温度调节装置5为空调;所述两个 The chamber door 3 faces the inlet end and the outlet end of the drum test bench 2 respectively; an earplug box 6 suspended on the sound insulation wall 4 is arranged outside the working room 1 . Wherein, the perlite sound-absorbing board 41, the vacuum glass layer 42, and the cement sawdust sound-absorbing board 43 all have a thickness of 5 cm.

[0021] 所述工作室1的墙体为隔音墙4,隔音墙4包括珍珠岩吸音板41、真空玻璃层42、水泥木屑吸声板43,其中珍珠岩吸音板41位于最内侧。 隔音墙4最外侧为水泥木屑吸声板43,将其设置在隔音墙4的最外侧,能够有效避免车间厂房内其他工作对隔音墙4的碰撞损伤,提高使用寿命,确保外观始终良好。 A vacuum glass layer 42 is arranged between the perlite sound-absorbing board 41 and the cement wood chip sound-absorbing board 43 . 此外,所述珍珠岩吸音板41与真空玻璃层42之间、真空玻璃层42与水泥木屑吸声板43之间均充填...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com