Non-deflection rod type high-frequency tuning mass damper

A technology of tuning mass and deflection rod, applied in the direction of protective buildings/shelters, building components, building structures, etc., can solve the problem of unstable working attitude of auxiliary mass, unable to guarantee the balance of auxiliary mass, working frequency and design Frequency deviation and other problems, to achieve the effect of large natural frequency range, optimized lateral stiffness and vertical stiffness, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

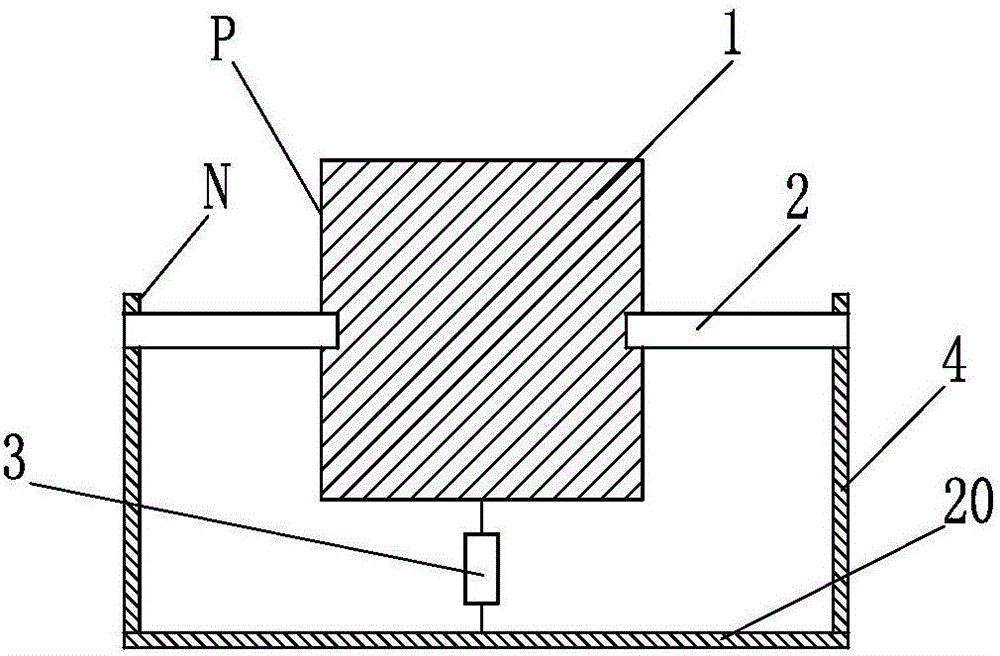

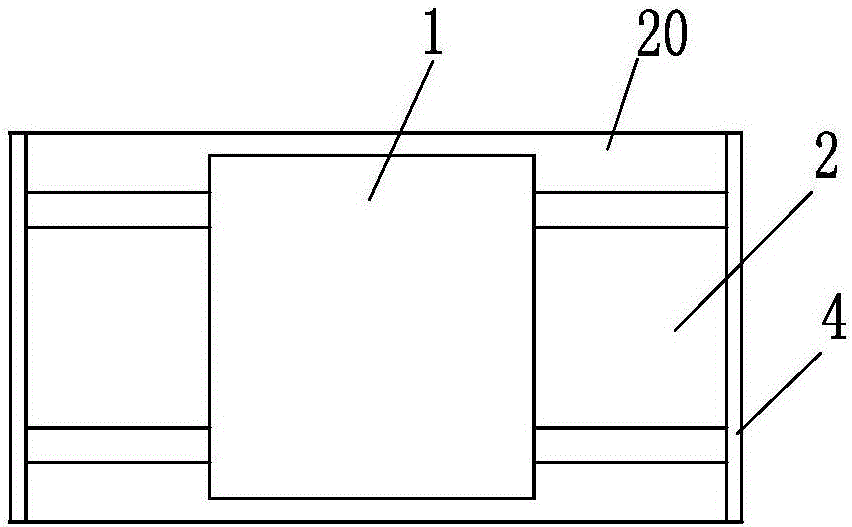

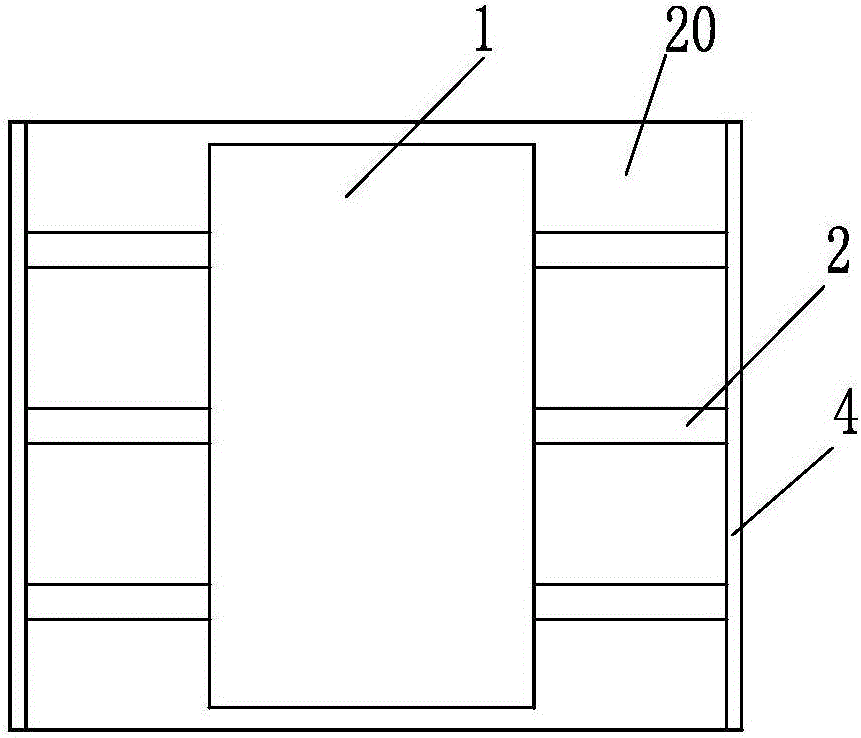

[0046] like Figure 4 , Figure 5 The non-deflection rod-type high-frequency tuning mass shock absorber of the present invention shown includes a mass block 1, an elastic element 2 and a damping element 3. The elastic element 2 is composed of an elastic rod made of two steel rods, and the two elastic rods are The ends are respectively supported on the bracket 4 and welded and fixed together with the bracket 4. The mass block 1 is arranged on the elastic rod, and the elastic rod penetrates the mass block 1 and is welded and fixed together with the mass block. The resultant force at least passes through the center of mass of the mass block or near the center of mass in the vertical component force; the damping element 3 is arranged under the mass block 1, and the damping element 3 is specifically a small-hole throttling damper, one end of which is connected to the mass block 1, and the other One end is connected with the connecting bottom plate 20 of the bracket 4; a frequency ...

Embodiment 3

[0051] like Figure 7 and Figure 8 The difference between the deflection-rod-type high-frequency tuning mass damper of the present invention shown in Embodiment 2 is that the elastic element 2 is composed of an aluminum alloy elastic rod with a rectangular cross-sectional shape. In order to prevent the axial movement of the elastic rod Moving, the two ends of the corresponding elastic rods on the outside of the bracket 4 are respectively provided with stoppers 5 and fasteners 6; in addition, the non-deflection rod type high-frequency tuned mass damper described in this example also includes a frequency adjustment device, the The frequency adjustment device includes two frequency adjustment bushings 7. The frequency adjustment bushings 7 are located on both sides of the mass block 1 and are arranged symmetrically. They are sleeved and fixed on the elastic rod by fastening screws 8. fixed on the elastic rod; in addition, the elastic element 3 includes two elastic shear dampers...

Embodiment 4

[0057] like Figure 9 and Figure 10 The difference between the non-deflection rod type high-frequency tuning mass damper of the present invention and the second embodiment is that the elastic element 2 includes four elastic rods, and the outer surface of the middle part of the elastic rods is provided with threads; in addition, both sides of the mass block 1 are fixed The ear plate 9 is set, and the elastic rod is set through the ear plate 9 to realize the support of the mass block 1; thirdly, in order to prevent the elastic rod from moving axially, stoppers 5 are respectively arranged on the outside of the bracket 4 corresponding to the two ends of the elastic rod and fasteners 6; fourthly, a lock nut 10 and a frequency adjustment device are arranged on the elastic rod, and the frequency adjustment device includes frequency adjustment sleeves 32 arranged in pairs, and the frequency adjustment sleeves 32 are specifically thickened The locking nuts are arranged symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com