Subway foundation pit anchor rope processing method

A processing method and anchor cable technology, which can be used in excavation, infrastructure engineering, sheet pile walls, etc., can solve problems affecting the normal operation of the station, and achieve the effects of protecting safety, economical solutions, and reducing collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

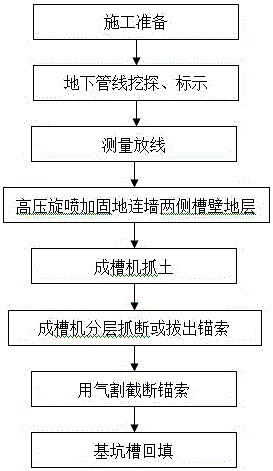

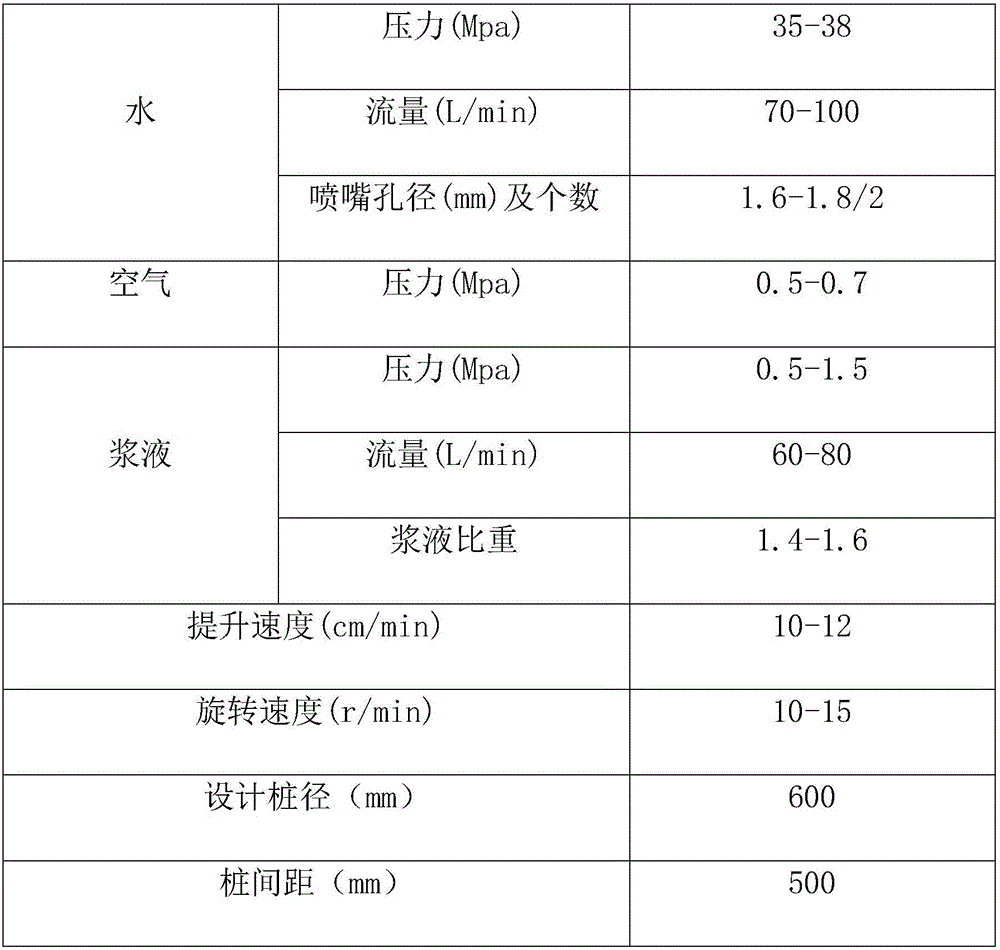

[0061] A method for treating the anchor cables of a subway foundation pit, which adopts the construction plan of the underground continuous wall groove wall high-pressure rotary spraying reinforcement + hydraulic groove forming machine (the knife edge is made of hard alloy) to directly grab and break the anchor cables; The pipelines are mainly two DN1200 raw water pipes. Since the station cannot be moved before construction, and there are waste sewage pipelines within the guide wall of the diaphragm wall, it is necessary to isolate the underground pipelines with high-pressure rotary grouting piles before the treatment of anchor cables and waste sewage pipes. The measures of inserting section steel are used to optimize the allocation of engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com