A kind of preparation method of polyester fdy mother silk and monofilament thereof

A technology of mother silk and polyester, applied in the field of preparation of polyester FDY mother silk and its monofilament, can solve the problems that the production process cannot meet the market demand, the uneven dyeing performance of monofilament, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

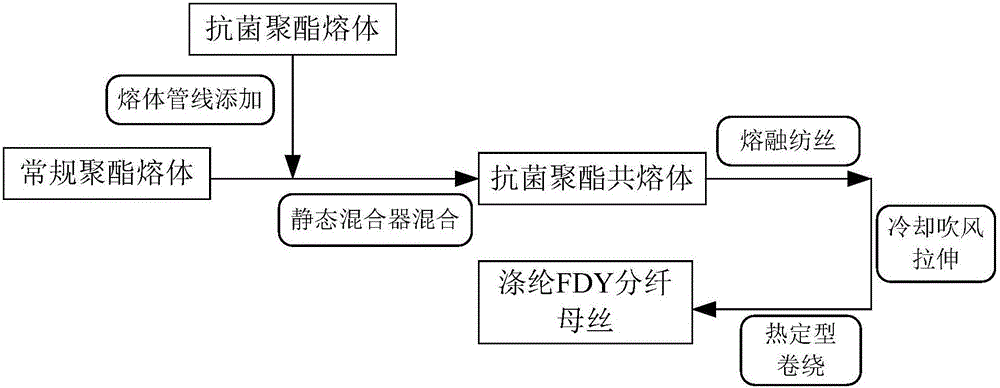

Image

Examples

Embodiment 1

[0034]A preparation method of polyester FDY mother silk, the antibacterial polyester melt containing cuprous material is added into the conventional polyester melt pipeline by means of melt direct spinning pipeline, and passed through the static mixer in the melt pipeline Mixing, and then through melt spinning, cooling, drafting, heat setting and winding processes to obtain polyester FDY fiber-divided mother silk. The specific process is: spinning temperature 292°C, wind temperature 16-18°C, wind speed 0.7-0.85m / s, drawing temperature 95°C, drafting ratio 1.8-2.2 times, heat setting temperature 150°C, winding tension control It is 2.2~2.5cN, and the winding speed is 3900~4500 m / min.

[0035] The mass ratio of antibacterial polyester melt containing cuprous material to conventional polyester melt is 1:8;

[0036] The number of holes in the mother silk spinneret is 6 to 144 holes, and the denier of the mother silk is 0.3 to 20D;

[0037] The production process of monofilaments...

Embodiment 2

[0057] A preparation method of polyester FDY mother silk, the antibacterial polyester melt containing cuprous material is added into the conventional polyester melt pipeline by means of melt direct spinning pipeline, and passed through the static mixer in the melt pipeline Mixing, and then through melt spinning, cooling, drafting, heat setting and winding processes to obtain polyester FDY fiber-divided mother silk. The specific process is: spinning temperature 292°C, wind temperature 16-18°C, wind speed 0.7-0.85m / s, drawing temperature 95°C, drafting ratio 1.8-2.2 times, heat setting temperature 150°C, winding tension control It is 2.2~2.5cN, and the winding speed is 3900~4500 m / min.

[0058] The mass ratio of antibacterial polyester melt containing cuprous material to conventional polyester melt is 1:12;

[0059] The number of holes in the mother silk spinneret is 6 to 144 holes, and the denier of the mother silk is 0.3 to 20D;

[0060] The production process of monofilamen...

Embodiment 3

[0079] A preparation method of polyester FDY mother silk, the antibacterial polyester melt containing cuprous material is added into the conventional polyester melt pipeline by means of melt direct spinning pipeline, and passed through the static mixer in the melt pipeline Mixing, and then through melt spinning, cooling, drafting, heat setting and winding processes to obtain polyester FDY fiber-divided mother silk. The specific process is: spinning temperature 292°C, wind temperature 16-18°C, wind speed 0.7-0.85m / s, drawing temperature 95°C, drafting ratio 1.8-2.2 times, heat setting temperature 150°C, winding tension control It is 2.2~2.5cN, and the winding speed is 3900~4500 m / min.

[0080] The mass ratio of the antibacterial polyester melt containing cuprous material to the conventional polyester melt is 1:15;

[0081] The number of holes in the mother silk spinneret is 6 to 144 holes, and the denier of the mother silk is 0.3 to 20D;

[0082] The production process of mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com