A kind of ceramic coating for glass-based solar backplane and preparation method thereof

A technology for solar backplanes and ceramic coatings, applied in the direction of reflection/signal coatings, coatings, semiconductor devices, etc., can solve problems such as loss of protection of solar cell components, environmental pollution of operators, separation between layers, etc., to prevent sagging, Prevent glass warping and reduce the effect of proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

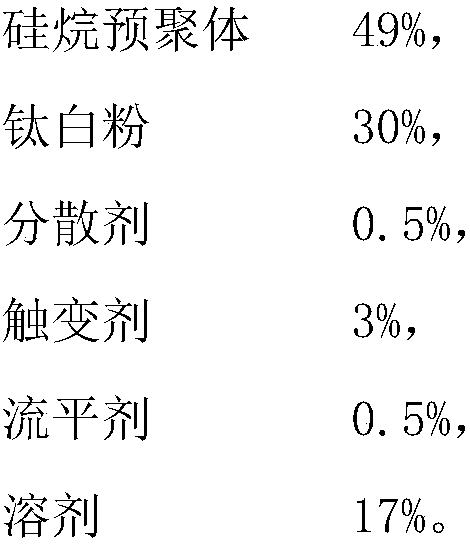

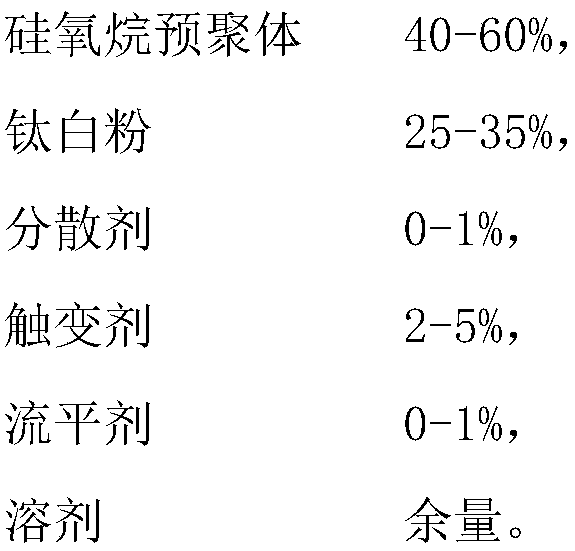

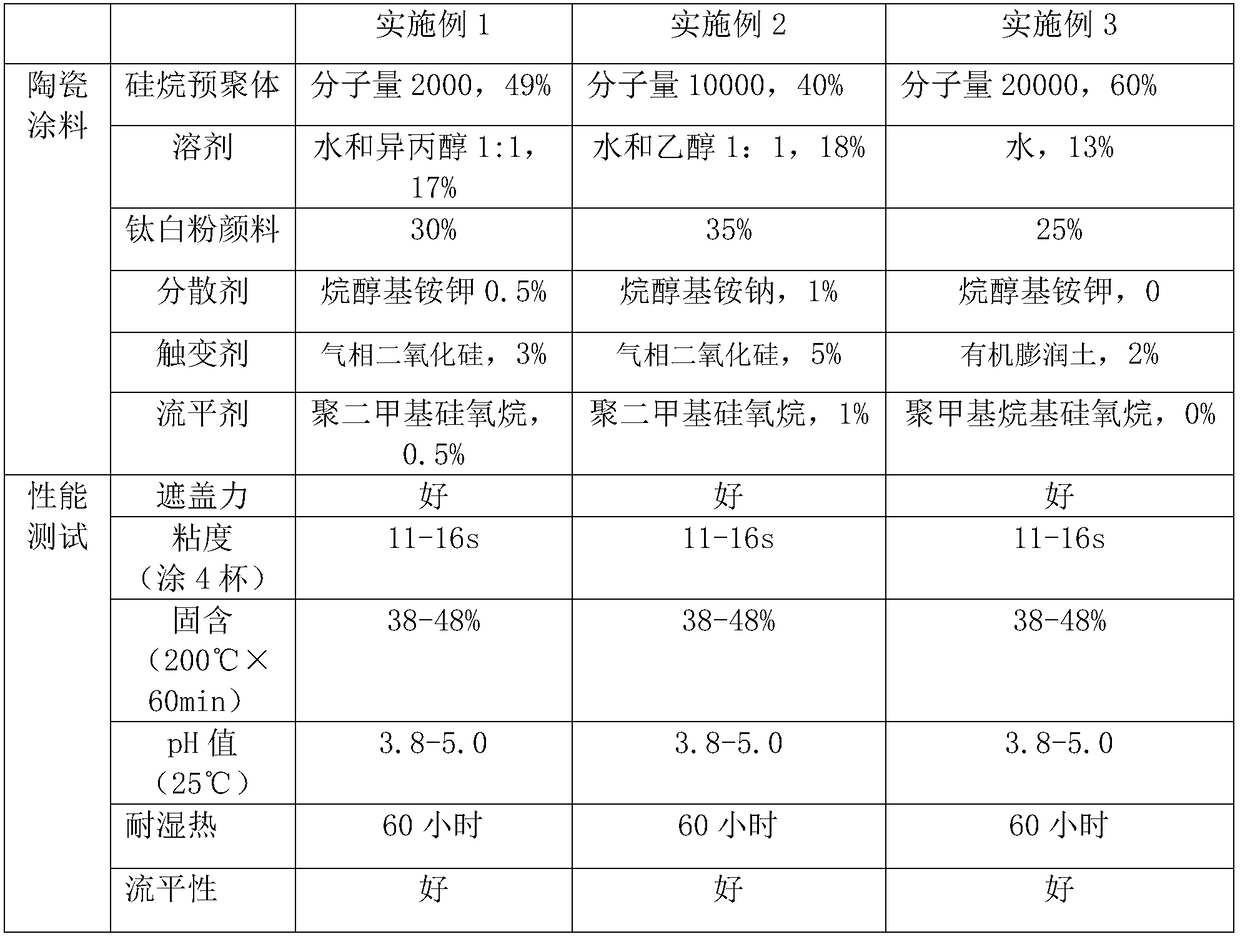

[0039] Embodiments 1-3 provide a ceramic coating for solar back panels, the components and corresponding contents included are shown in Table 1 below:

[0040] Table 1

[0041]

[0042] The preparation method of the above-mentioned ceramic coating for solar backboard, comprises the following steps:

[0043] Mix the solvent, titanium dioxide, and dispersant, and ball mill to obtain a slurry; mix the slurry with the siloxane prepolymer, add the thixotropic agent and leveling agent and mix to obtain a ceramic coating.

[0044] Wherein, the time of the ball milling is 0.5-2 hours; the ball milling adopts zirconium beads; the equipment of the ball milling is a grinding machine; the particle size of the zirconium beads is 1.5-3mm.

[0045] The slurry or the ceramic coating obtained by the method of the present invention are all white.

Embodiment 4-6

[0047] Examples 4-6 used the ceramic coating prepared in Example 1 to prepare a solar backsheet, and the preparation parameters and performance of the solar backsheet are shown in Table 2 below:

[0048] Table 2

[0049]

[0050]

[0051] The preparation method of the solar backboard of the above-mentioned ceramic coating is specifically as follows: the ceramic coating is coated on the solar backplane substrate by rolling coating, solidified and cooled;

[0052] Wherein, the solar backplane substrate specifically refers to inorganic glass; the curing conditions are: 600-800°C, 2-5 minutes; the equipment used for the curing is a high-temperature furnace; the cooling specifically refers to cold air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com