Road asphalt modifier containing double-ended hydroxyl styrene-butadiene rubber and preparation and usage method

A technology of double-terminated hydroxybutylbenzene and terminated hydroxybutadiene is applied in the field of asphalt modifiers, which can solve the problems of endangering the health of operators, high energy consumption of shearing equipment, and difficulty in ensuring the stability of asphalt, and achieve the modification effect. Significant, low residual monomer content, low temperature performance and improved water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

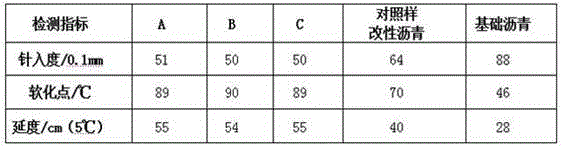

Examples

Embodiment 1

[0038] The invention provides a road asphalt modifier containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber, which is composed of the following components, all of which are parts by weight:

[0039] 60 parts of double-ended hydroxybutadiene liquid rubber;

[0040] 8 parts of nanometer calcium carbonate;

[0041] 3 parts of white carbon black;

[0042] 6 parts of nano silicon dioxide;

[0043] Diatomaceous earth 5 parts.

[0044] The road asphalt improver containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber of the present invention is realized through the following preparation process:

[0045] (1) Styrene purification: Distill styrene under reduced pressure at 40°C and -0.1MPa pressure, take the middle 80% fraction, add 0.05wt% desiccant calcium hydride and store it at low temperature for later use.

[0046] (2) Connect the stainless steel pressure-resistant polymerization kettle with the vacuum pump / argon system, vacuumize and fill...

Embodiment 2

[0054] The invention provides a road asphalt modifier containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber, which is composed of the following components, all of which are parts by weight:

[0055] 70 parts of double-ended hydroxybutadiene liquid rubber;

[0056] 10 parts of nano calcium carbonate;

[0057] White carbon black 5 parts;

[0058] 10 parts of nano silicon dioxide;

[0059] Diatomaceous earth 6 parts.

[0060] The road asphalt improver containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber of the present invention is realized through the following preparation process:

[0061] (1) Styrene purification: Distill styrene under reduced pressure at 50°C and -0.09MPa pressure, take the middle 80% fraction, add 0.1wt% desiccant calcium hydride and store it at low temperature for later use.

[0062] (2) Connect the stainless steel pressure-resistant polymerization kettle with the vacuum pump / argon system, vacuumize and fill with ...

Embodiment 3

[0070] The invention provides a road asphalt improver containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber, which consists of the following parts, all of which are parts by weight:

[0071] 80 parts of double-ended hydroxybutadiene liquid rubber;

[0072] 15 parts of nano calcium carbonate;

[0073] 7 parts of white carbon black;

[0074] 8 parts of nano silicon dioxide;

[0075] Diatomaceous earth 8 parts.

[0076] The road asphalt improver containing double-ended hydroxy-butadiene styrene-butadiene liquid rubber of the present invention is realized through the following preparation process:

[0077] (1) Styrene purification: Distill styrene under reduced pressure at 60°C and -0.09MPa pressure, take the middle 80% fraction, add 0.08wt% desiccant calcium hydride and store it at low temperature for later use.

[0078] (2) Connect the stainless steel pressure-resistant polymerization kettle with the vacuum pump / argon system, vacuumize and fill with argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com