Method for synthesizing graphene-polydimethylsiloxane (PDMS) functional sponge

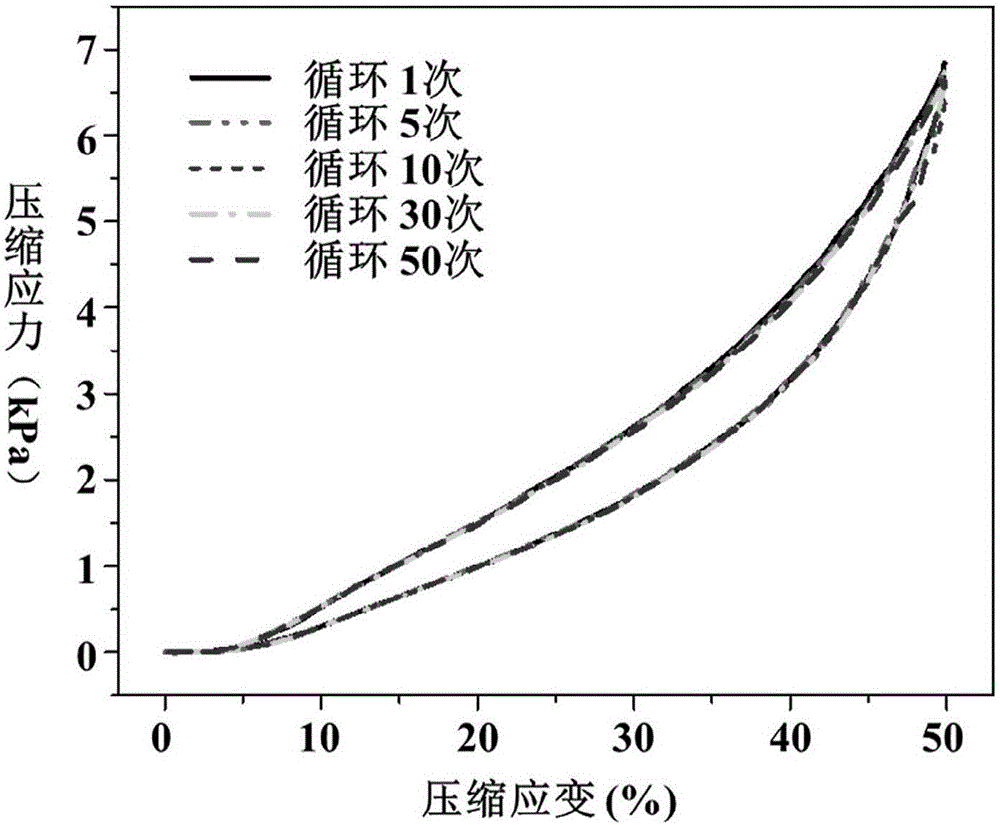

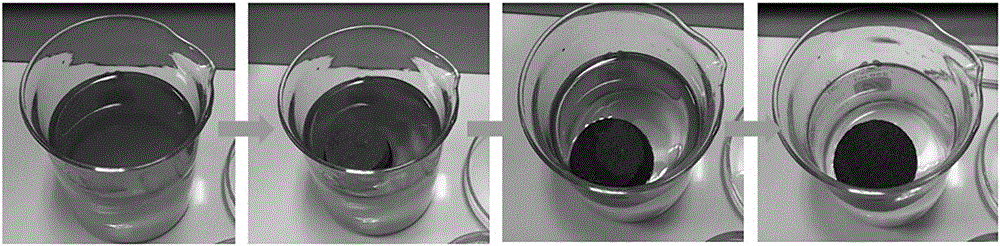

A technology of polydimethylsiloxane and synthesis method, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem that nano-fillers are easy to fall off, easy to agglomerate, and production costs High-level problems, to achieve the effect of good recycling capacity, high adsorption capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

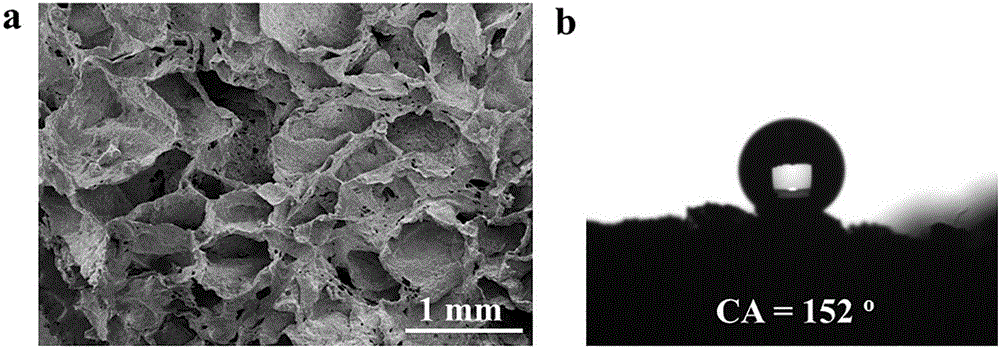

[0034] Take 1g of PDMS prepolymer to prepare a solution of ethyl acetate with a concentration of 0.05g / ml, add 15mg of graphene powder to the above mixed solution, put the entire reaction system into an ultrasonic cleaner, start timing, and continue ultrasonic (power Density 1.5W / cm 2 , frequency 53kHz). When the ultrasonic time reaches 30min, add synthetic PDMS curing agent (the mass ratio of prepolymer and curing agent is 10:1) and sea crystal salt templating agent (10g) in the system; when the ultrasonic time reaches 120min, the mixed solution The ethyl acetate volatilized completely, and the gray viscous graphene-silicone rubber-sea crystal composite material was obtained. Put the composite material into a mold, dry and calcinate at 60-90°C for 12 hours, put it into hot water at 80-100°C to dissolve the template, repeat 3 times, and obtain a graphene-silicone rubber functional sponge after drying at 60-80°C. The contact angle of the surface of the structure to water is 1...

Embodiment 2

[0036] Take 1g of PDMS prepolymer to prepare a solution of ethyl acetate with a concentration of 0.05g / ml, add 30mg of graphene powder to the above mixed solution, put the entire reaction system into an ultrasonic cleaner, start timing, and continue ultrasonic (power Density 1.5W / cm 2, frequency 53kHz). When the ultrasonic time reaches 30min, add synthetic PDMS curing agent (the mass ratio of prepolymer and curing agent is 10:1) and sea crystal salt templating agent (10g) in the system; when the ultrasonic time reaches 120min, the mixed solution The ethyl acetate volatilized completely to obtain a gray sticky graphene-silicone rubber-sea crystal salt composite material. Put the composite material into a mold, dry and calcinate at 60-90°C for 12 hours, dissolve the template in hot water at 80-100°C, repeat 3 times, and obtain a graphene-silicone rubber functional sponge after drying at 60-80°C.

[0037] Its microstructure was characterized by scanning electron microscopy (see...

Embodiment 3

[0039] Get 1g of PDMS prepolymer to prepare a solution of ethyl acetate with a concentration of 0.05g / ml, add 15mg of graphene to the above mixed solution, put the whole reaction system into an ultrasonic cleaner, start timing, and continue ultrasonic (power density 1.5 W / cm 2 , frequency 53kHz). When the ultrasonic time reaches 30min, add synthetic PDMS curing agent (the mass ratio of prepolymer and curing agent is 10:1) and soft white sugar template (6g) in the system; when the ultrasonic time reaches 120min, the acetic acid in the mixture Ethyl ester volatilizes completely, obtains the gray viscous graphene-silicone rubber-soft white sugar composite material. Put the composite material into a mold, dry and calcinate at 60-90°C for 12 hours, put it into hot water at 80-100°C to dissolve the template, repeat 3 times, and obtain a graphene-silicone rubber functional sponge after drying at 60-80°C. The contact angle of the surface of the structure to water is 142°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com