A kind of ammonia recovery tower used in ammonium nitrate production equipment

An ammonia recovery tower and production equipment technology, applied in the field of ammonium nitrate production devices, can solve the problems of poor gas-liquid separation effect, unstable operation, bad operating conditions, etc., to reduce water treatment pressure, reduce production costs, and reduce gas ammonia. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

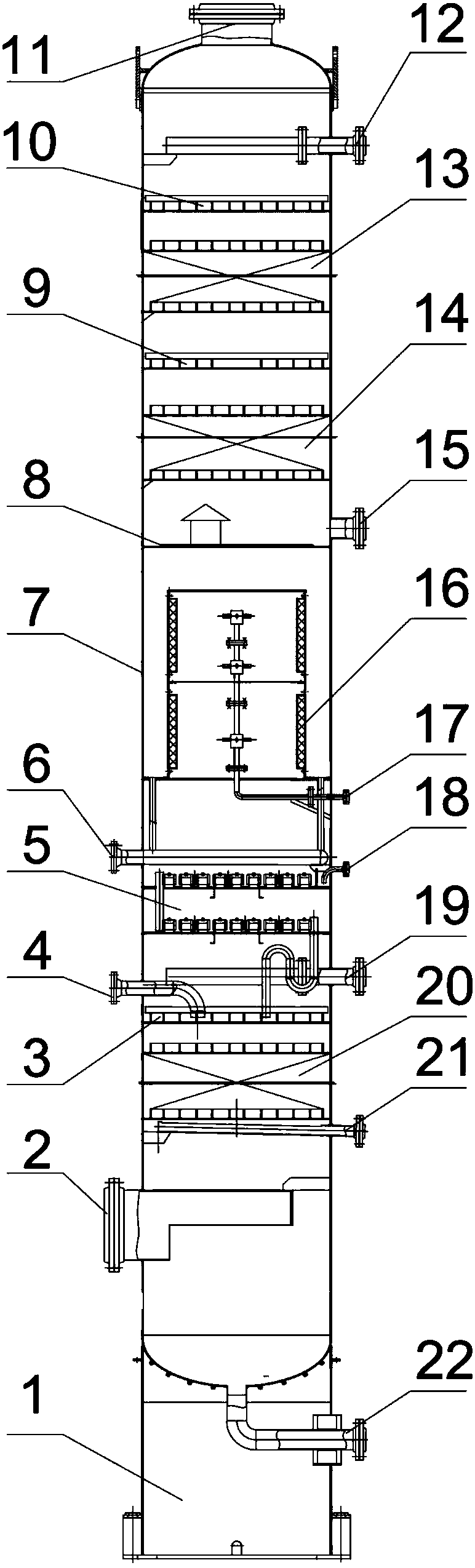

[0022] refer to figure 1 , an ammonia recovery tower used in an ammonium nitrate production equipment of the present invention comprises a tower body 7, the top of the tower body 7 is provided with an ammonia-containing mixed circulating gas outlet 11, and a tower below the ammonia-containing mixed circulating gas outlet 11 The body 7 is sequentially provided with a neutralization waste liquid inlet 12, a stripping liquid outlet 15, a circulating ammonium nitrate solution inlet 19 and an ammonia-containing mixed gas inlet 2 from top to bottom. The bottom of the tower body 7 is provided with an ammonium nitrate solution outlet 22. The ammonia-containing mixed circulating gas outlet 11 is connected to the ammonia-containing mixed gas inlet 2 through a circulating mechanism. The circulation mechanism of this embodiment can use a fan, and the circulating ammonia-containing mixed gas can be sent out from the top of the tower and returned to the bottom of the tower through the fan. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com