Synthesis method of Nu-6(1) molecular sieve

A molecular sieve, nu-6 technology, applied in the field of synthesis of Nu-6 molecular sieves, can solve the problems of long production cycle and heavy labor, and achieve the effects of reduced content, large application potential, and uniform crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The molar ratio of synthesized Nu-6(1) is: 0.278Na 2 O:1SiO 2 :0.02Al 2 O 3 :0.13 4,4’-Bipyridine:0.5H 2 O, add 1wt% seed crystals, statically crystallize, and react at 135°C for 72 hours to prepare Nu-6(1) molecular sieve.

[0049] 1) Mix 0.912 g of 4,4'-bipyridine and 5.040 g of absolute ethanol to obtain solution A, 10.158 g of sodium silicate solution and 5.960 g of deionized water to obtain solution B, 0.310 g of aluminum sulfate, and 12.110 g of deionized water. Mix water and 0.760 g of concentrated sulfuric acid to obtain C solution, and stir for 2 hours;

[0050] 2) Add solution B dropwise to solution A prepared in step 1), stir for 1 hour, then add solution C dropwise to the mixed solution of A and B, after aging at room temperature for 24 hours, add 27 mg of Nu-6(1) Seed crystal.

[0051] Dry the mother liquor in step 2) at 80°C for 24 hours, and grind into powder;

[0052] 3) Pour the powder into a polytetrafluoroethylene reactor, add 0.522 g of deionized water, sti...

Embodiment 2

[0058] The molar ratio of synthesized Nu-6(1) is: 0.278Na 2 O:1SiO 2 :0.02Al 2 O 3 :0.065 4,4’-Bipyridine:0.5H 2 O, adding 5wt% seed crystals, static crystallization, and reacting at 135°C for 72 hours to prepare Nu-6(1) molecular sieve.

[0059] The difference from Example 1 is that in step 1), 0.458 g of 4,4'-bipyridine is added to solution A; in step 2), 135 mg of Nu-6(1) seed crystal is added; in step 4), 0.478 is added G deionized water, add acid to adjust the pH to 1.0. The remaining steps and parameters are the same as in Example 1.

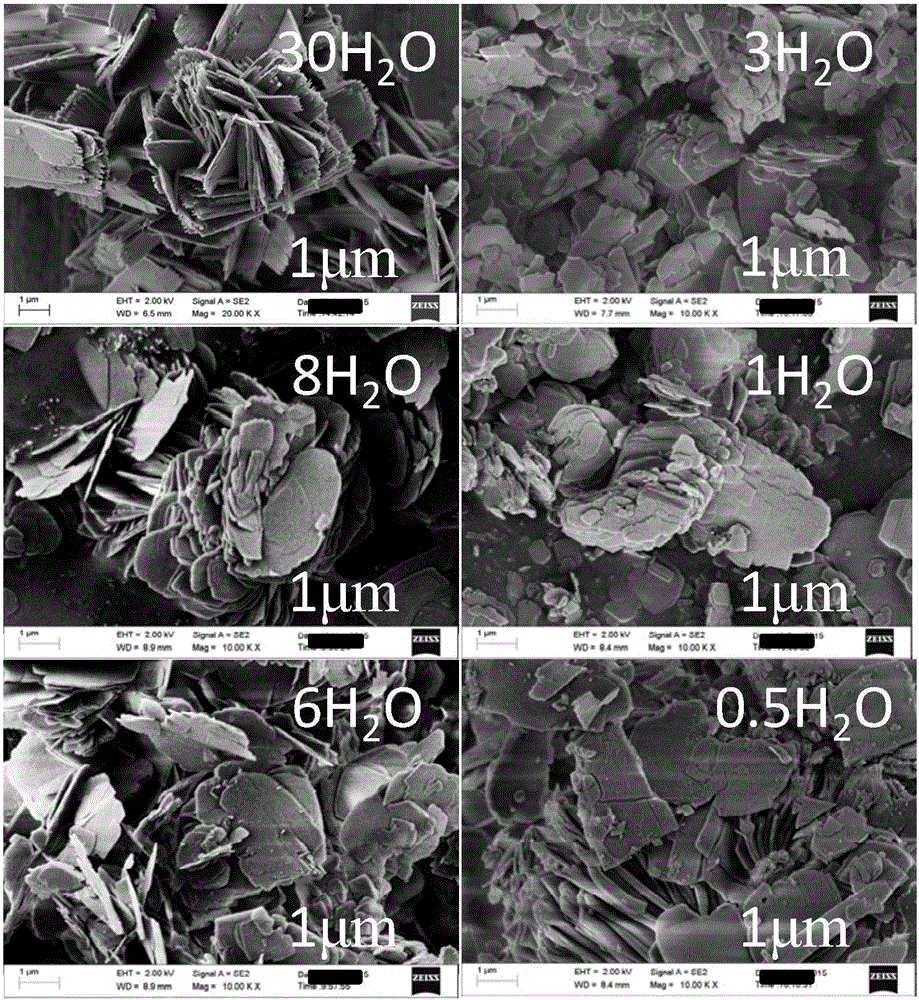

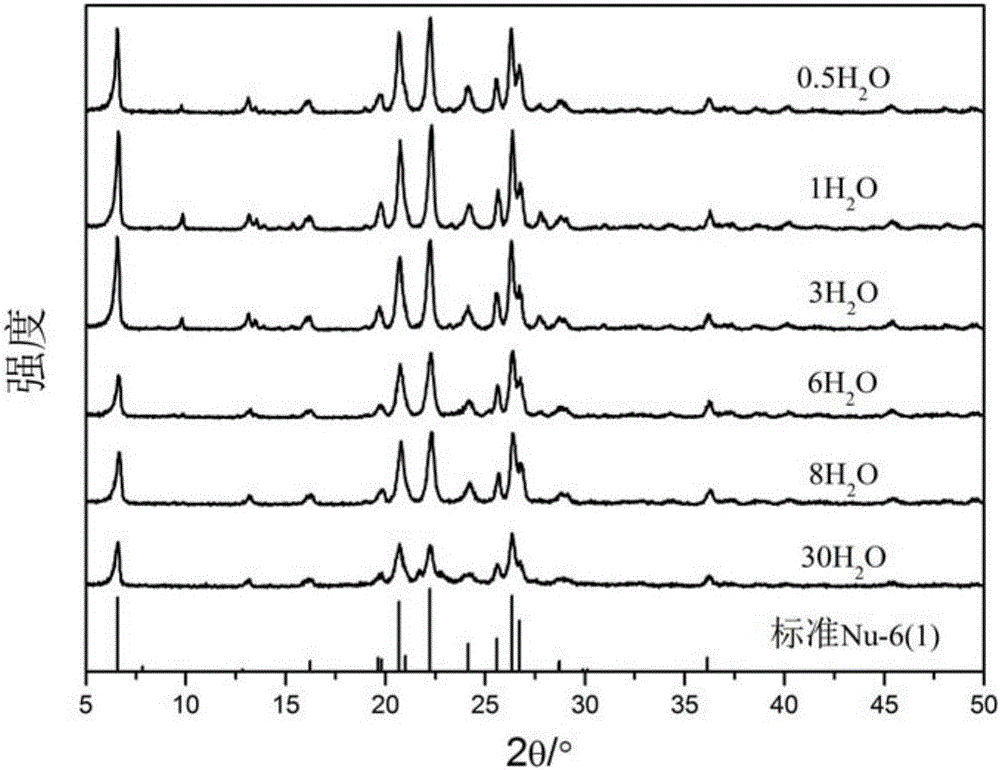

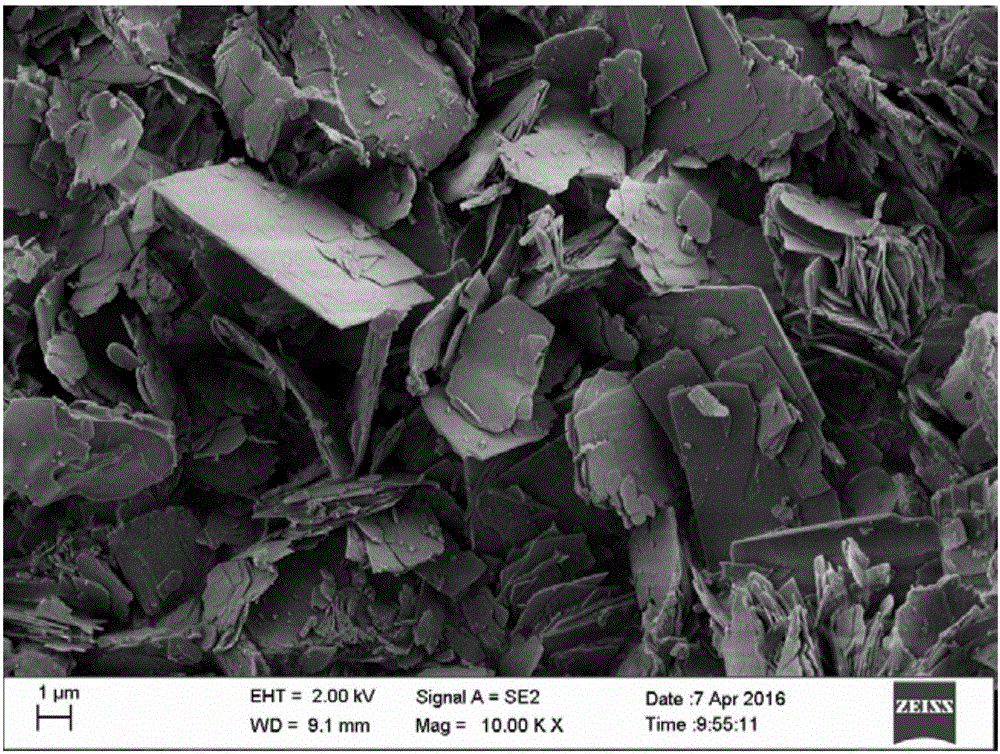

[0060] Figure 7 This is a scanning electron micrograph of Nu-6(1) molecular sieve. Nu-6(1) molecular sieve crystals are about 1 micron flaky crystals with relatively uniform crystal size. Compared with the traditional Nu-6(1) synthesis method, the ratio of water to silicon decreased from 30 to 0.5, and the ratio of silicon to template decreased from 0.13 to 0.065. The conditions of hydrothermal synthesis were changed from dynamic crystallizat...

Embodiment 3

[0063] The molar ratio of synthesized Nu-6(1) is: 0.278Na 2 O:1SiO 2 :0.02Al 2 O 3 :0.065 4,4’-Bipyridine:3H 2 O, add 1wt% seed crystals, statically crystallize, and react at 135°C for 72 hours to prepare Nu-6(1) molecular sieve.

[0064] The difference from Example 1 is that in step 1), 0.458 g of 4,4'-bipyridine is added to solution A; in step 4), 1.632 g of deionized water is added, and acid is added to adjust the pH to 11.0. The remaining steps and parameters are the same as in Example 1.

[0065] Picture 9 This is a scanning electron micrograph of Nu-6(1) molecular sieve. Nu-6(1) molecular sieve crystals are about 1 micron flaky crystals with relatively uniform crystal size. Compared with the traditional Nu-6(1) synthesis method, while the ratio of water to silicon is reduced from 30 to 3, the ratio of silicon to template is reduced from 0.13 to 0.065. The conditions of hydrothermal synthesis are changed from dynamic crystallization and reaction for 96 hours. The improvement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com