Preparation method of modified phenolic resin base activated carbon and supercapacitor

A technology of phenolic resin and resole phenolic resin, which is applied in the preparation method of graphene-modified phenolic resin-based activated carbon and the field of supercapacitors, can solve the problems of low mesoporosity, small specific surface area, and low conductivity, and achieve high porosity rate, high conductivity, and the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

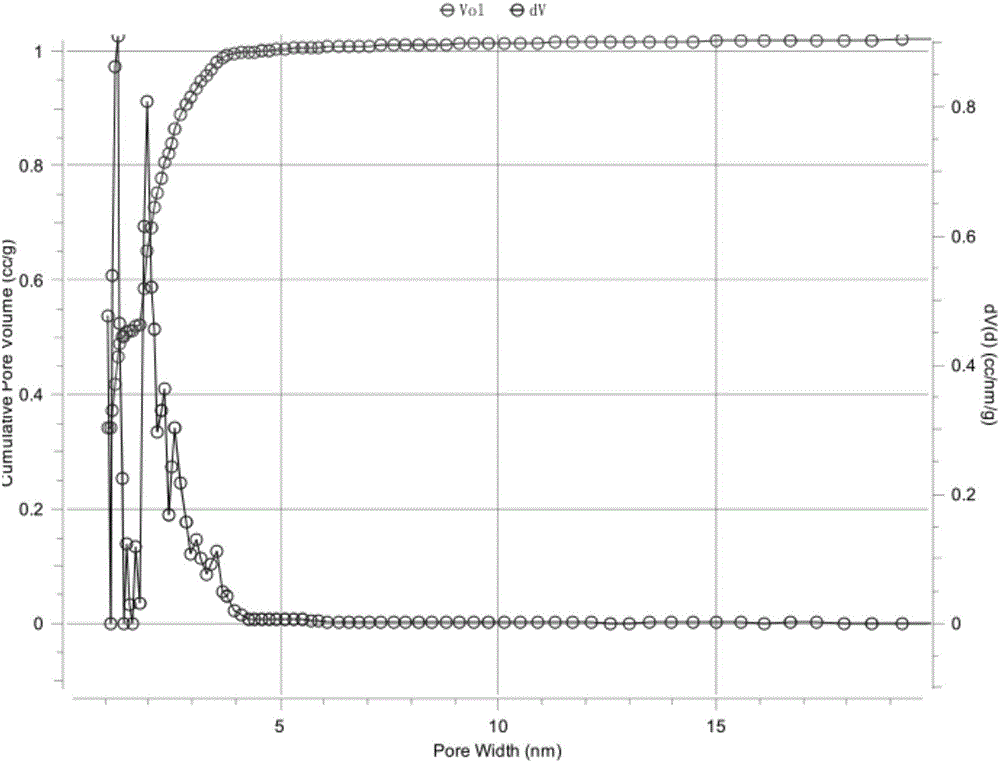

Image

Examples

preparation example Construction

[0042] The invention provides a kind of preparation method of modified phenolic resin-based activated carbon, comprising the following steps:

[0043] A) after the resole phenolic resin is mixed with the graphene oxide solution, a mixture is obtained;

[0044] B) after foaming the mixture obtained by the above steps, curing accelerator, blowing agent and surfactant, a composite phenolic resin foam is obtained;

[0045] C) under the condition of inert gas and / or nitrogen, after the composite phenolic resin foam that above-mentioned step is obtained is carbonized, obtain carbonized material;

[0046] D) After the carbonized material obtained in the above steps is mixed with alkali, after activation under the conditions of inert gas and / or nitrogen, the primary product of activated carbon is obtained;

[0047]E) The activated carbon primary product obtained in the above steps is subjected to heat treatment under the protection of a reducing gas to obtain a modified phenolic resi...

Embodiment 1

[0073] Get 100g the resole phenolic resin (F / P=1.3) that is prepared by phenol and paraformaldehyde, add the ethanol solution 100mL (graphene oxide monolayer ratio >95%) that contains 2g fully exfoliated graphene oxide wherein, Stir at high speed under ultrasonic to disperse for 60min. Then the obtained solution was distilled off under reduced pressure to remove the ethanol solvent to obtain a resole phenolic resin in which graphene oxide was fully dispersed.

[0074] Then add 0.5g of surfactant Tween-80, 10mL of foaming agent petroleum ether, 0.5mL of curing accelerator mixed acid solution (p-toluenesulfonic acid:phosphoric acid=2:1), and foam at 70°C for 45min to obtain Phenolic foam.

[0075] Then put the phenolic foam into a muffle furnace protected by inert gas, and carbonize at 800°C for 2 hours to obtain a pre-carbonized product. Grind the pre-carbonized product into 50-100μm particles, add 100g of potassium hydroxide powder and mix well, add it into a pure nickel cru...

Embodiment 2

[0082] Get 100g of resole phenolic resin (F / P=1.5) prepared by resorcinol and formaldehyde aqueous solution, add the ethanol solution 100mL (graphene oxide monolayer ratio >95% that contains 1g fully exfoliated graphene oxide) wherein ), high-speed stirring and dispersing under ultrasonic for 60min. Then the obtained solution was distilled off under reduced pressure to remove the ethanol solvent to obtain a resole phenolic resin in which graphene oxide was fully dispersed.

[0083] Then add 1 g of surfactant polyoxypropylene ether, 10 mL of blowing agent n-pentane, and 1 g of curing agent oxalic acid, and foam at 80° C. for 60 minutes to obtain phenolic foam.

[0084] Then add the phenolic foam into a muffle furnace protected by inert gas, and carbonize it at 800°C for 2 hours to obtain a carbonized product; grind the pre-carbonized product into particles of 50-100 μm, add 200g of potassium hydroxide powder and mix well, add Place in a pure nickel crucible in a tube furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com