Circular tube conveyor material flow control device

A control device and conveyor technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve problems such as initiation accidents, pipe bursts on round pipe belt conveyors, uneven layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

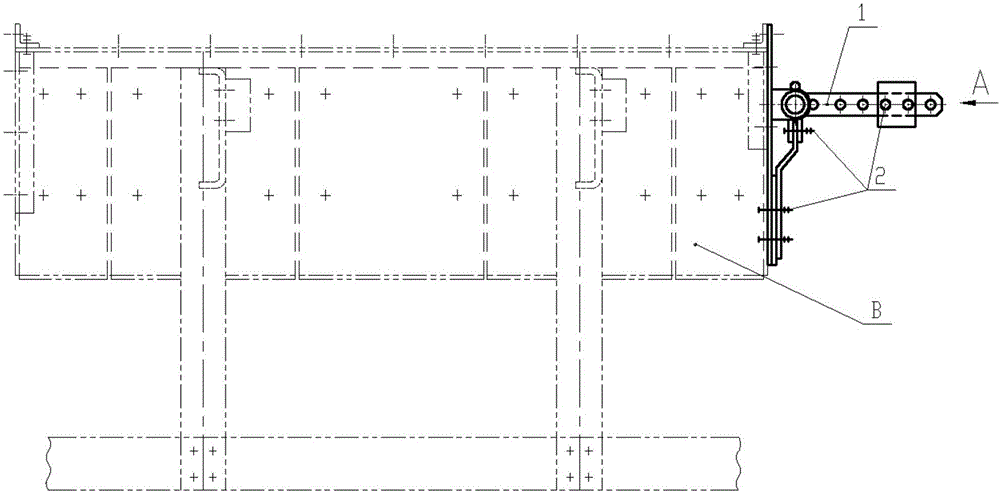

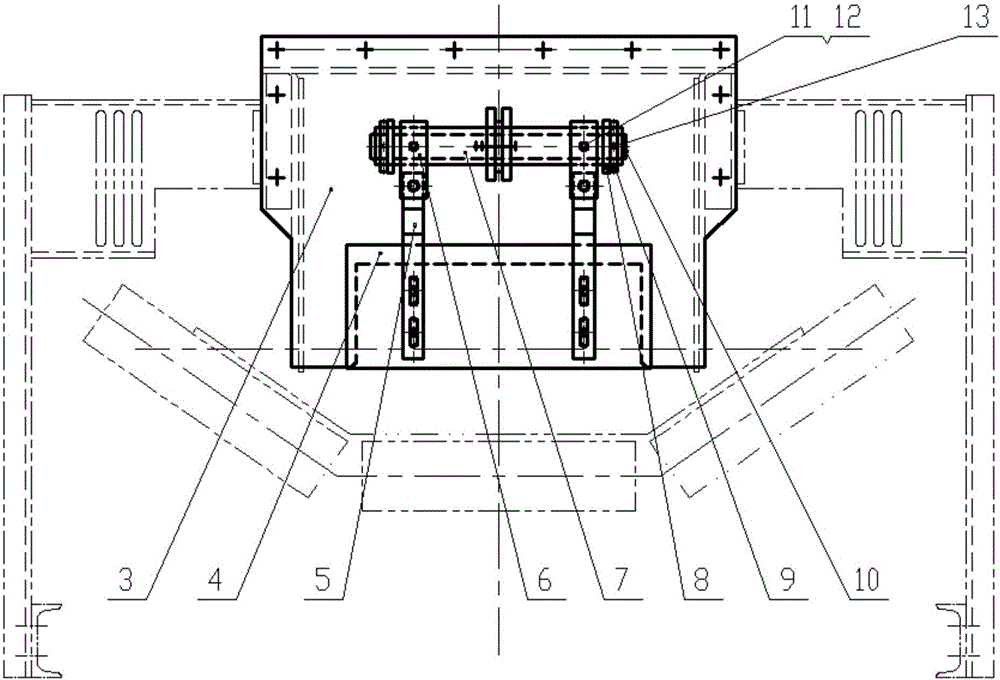

[0011] Referring to the accompanying drawings, a material flow control device for a round pipe conveyor includes an anti-tension counterweight device 1, a fastener 2, a baffle plate 3, an adjustment plate 4, an adjustment link plate 5, a joint ring 6, a shaft 7, and a fixed plate 8. Fixed ring 9, sealing plate 10, pin shaft 11, first cotter pin 12, second cotter pin 13, the material flow control device of the circular tube conveyor is installed at the front end of the material guide trough B, instead of the material guide The front curtain of groove B, the baffle plate 3 is made of 6mm thick steel plate, the upper three sides are flange-connected with the outlet of the front section of the material guide groove B, and the lower part has a rectangular opening, and the outside of the rectangular opening of the baffle plate 3 is covered by the adjustment plate 4 components. Fasteners 2 are used to connect the plate 4 and the adjusting connecting plate 5, the anti-tension counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com