Uniform-temperature superheater for waste incineration boiler and superheated steam heating method

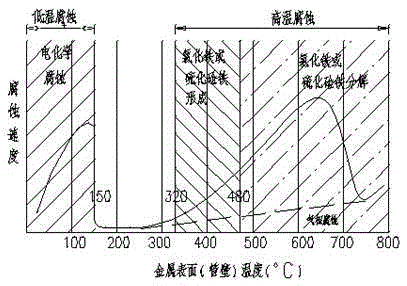

A technology of waste incineration and superheated steam, applied in combustion methods, incinerators, steam superheating, etc., can solve the problems of inability to guarantee long-term stable operation of boilers, large manufacturing accuracy errors, and difficulty in ensuring uniform cross-section, and achieve long-term stability. The effect of running, improving uniformity, preventing excessive tube temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail.

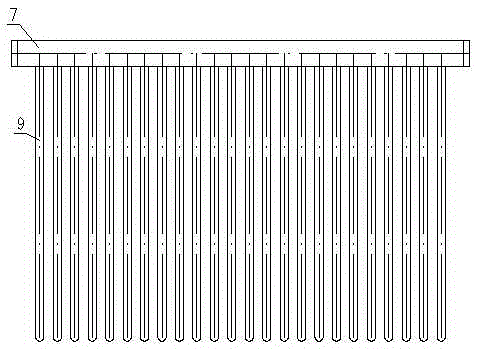

[0027] Such as Figure 4 to Figure 5 As shown, the homogeneous superheater used for waste incineration boilers in the present invention includes four unit tube groups 1, each unit tube group includes an inlet mixer 2, an outlet mixer 3 and is connected in parallel between the inlet mixer 2 and the Several U-shaped superheated tubes 4 between the outlet mixers 3, and the inner diameters and tube lengths of several U-shaped superheated tubes 4 in each unit tube group 1 are the same; the four unit tube groups 1 are arranged in sequence, and the first one The outlet mixer 3 of the unit tube group is connected with the inlet mixer 2 of the next unit tube group through several parallel connecting pipes 5;

[0028] The superheated steam heating method suitable for the above-mentioned homogeneous superheater used in waste incineration boilers, the following steps: A) Pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com