Superheater for Waste Heat Waste Heat Boiler and Superheated Steam Heating Method

A waste heat boiler and waste incineration technology, which is applied in the directions of steam superheating, steam generation, lighting and heating equipment, etc., can solve the problems that the long-term stable operation of the boiler cannot be guaranteed, the manufacturing accuracy error is also large, and the cross-section is difficult to ensure uniformity. Long-term stable operation, improved uniformity, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail.

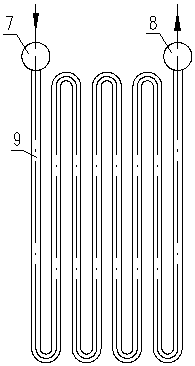

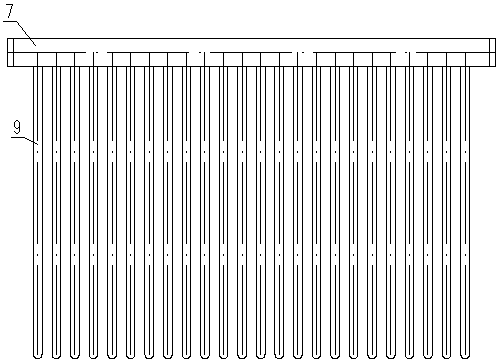

[0027] Such as Figure 4 to Figure 5 As shown, the superheater used in the waste incineration waste heat boiler of the present invention includes five superheater subunits 1, and each superheater subunit 1 includes an inlet mixer 2, an outlet mixer 3 and a parallel connection between the inlet mixer 2 and several U-shaped superheated tubes 4 between the outlet mixer 3, and the inner diameters and tube lengths of several U-shaped superheated tubes 4 in each superheater sub-unit are the same; five superheater sub-units 1 are arranged in sequence, Wherein the outlet mixer 3 of the previous superheater subunit is connected with the inlet mixer 2 of the next superheater subunit through eight equal temperature tubes 5, and the eight equal temperature tubes 5 are divided into four groups in pairs, each The two uniform temperature tubes 5 in the group are cross-connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com