Automatic three-dimensional warehousing equipment

An equipment and three-dimensional technology, applied in storage devices, transportation and packaging, conveyors, etc., can solve the problems of not meeting the needs of users, affecting the storage capacity of three-dimensional warehouses, and messy production sites, reducing the waiting time for material preparation and reducing warehouse management. Employee workload, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

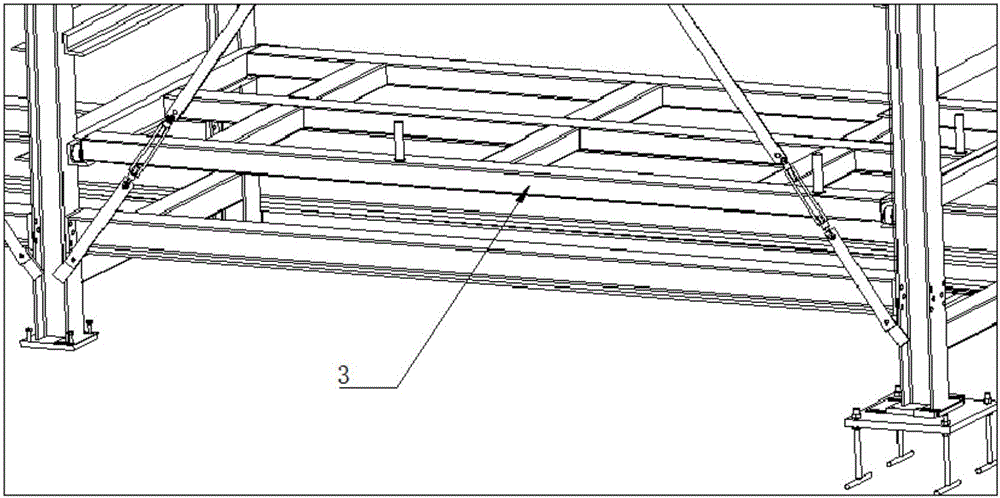

[0034] See Figure 1-Figure 2 , a kind of automatic three-dimensional storage equipment of the present invention, comprises three-dimensional shelf 2, heavy-duty stacker 1, position pallet 3 and PLC control system:

[0035] The heavy-duty stacker 1 is installed on one side of the three-dimensional shelf 2 through the sky rail 5 and the ground rail 6, see figure 2 , the three-dimensional shelf 2 is welded with a guide rail matching the storage tray 3, and the front of the storage tray 3 is welded with a hook plate 306, see Figure 10 ;

[0036] See Figure 5-Figure 9, the heavy-duty stacker 1 includes a stacker trolley 101, a column 102, a guide rail 106, a trolley roof frame 108, a lifting frame 103, a fork 105, an auxiliary support roller 104, a lifting motor 1010 and a travel motor 1012, the stacker The bottom of the trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com