Quick cooling type production mould for pedal main body of sea farming net cage

A rapid cooling and marine technology, applied in household appliances, other household appliances, applications, etc., can solve the problems of pedal body molding, slow cooling speed, low production efficiency, etc., to prevent deformation and ensure the effect of molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

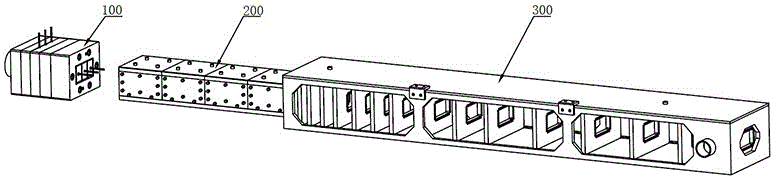

[0062] like figure 1 As shown, a quick-cooling type marine culture cage pedal main body production mold includes an extrusion die head 100, a vacuum cooling shaping mold 200 and a vacuum shaping water tank 300 connected in sequence.

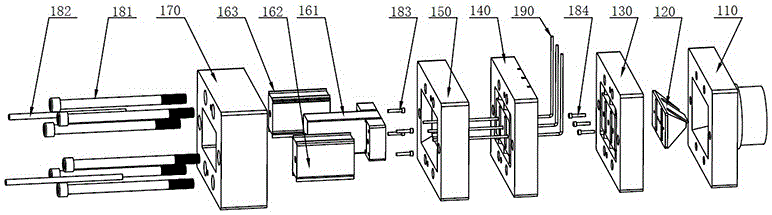

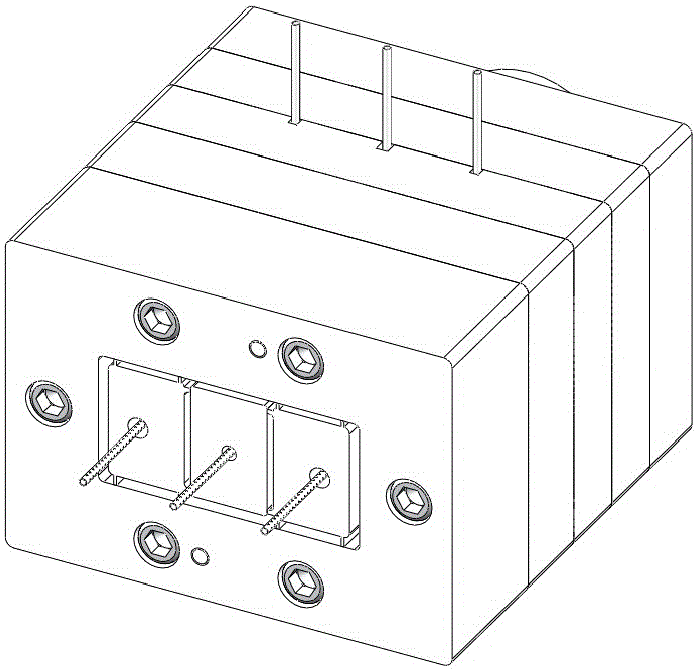

[0063] like Figure 2~6 and Figure 17 As shown, the extrusion die head 100 includes a distribution section, a compression section and a forming section, and an air-cooled copper pipe 190 runs through the end of the distribution section to the forming section. The splitter section includes a die base 110, a first splitter plate 130 located on one side of the die base 110, a splitter cone 120 fixed on the first splitter plate 130 by screws 184 and embedded in the inner cavity of the die base 110, and a splitter cone 120 located on one side of the die base 110. The second splitter plate 140 on one side of the first splitter plate 130; the compression section includes a compression plate 150 on one side of the second splitter plate 140; the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com