Inverted type drilling machine and operating method for machining fine drill holes

An operation method and an inverted technology, which is applied to the parts of boring machine/drilling machine, boring/drilling, metal processing equipment, etc., can solve the problem of drilling deviation due to the gravity of the drill bit itself, large energy loss of equipment and equipment, and processing accuracy. Poor and other problems, to achieve the effect of reducing the occupied area, saving energy, and reducing the cost of processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

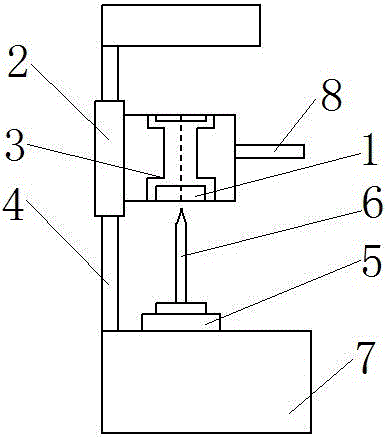

[0030] An operation method for fine drilling with an inverted drilling machine, the steps of the operation method are:

[0031] (1) Install the drill upside down on the drill box 5, and adjust the vertical angle of the drill to 90°;

[0032] (2) Put the workpiece 1 from bottom to top into the guide sleeve 2 fixed on the feed pallet 3, adjust the position of the workpiece 1, so that the center line of the processed hole coincides with the center axis of the drill, and the two The coincidence error of the center line is not greater than 2.0mm;

[0033] (3) When the power is turned on, the drill box 5 drives the drill bit 6 to rotate, so that the rotation speed of the drill bit 6 reaches 300r / min, and the cutting oil is passed into the drill bit 6 through the drill box 5, and the flow rate of the cutting oil is 50ml / s. The workpiece 1 is moved downwards driven by the feed pallet 3, and the feed rate is 0.8mm / r until the feeding movement of drilling is completed; the workpiece is...

Embodiment 2

[0038] An operation method for fine drilling with an inverted drilling machine, the steps of the operation method are:

[0039] (1) Install the drill upside down on the drill box 5, and adjust the vertical angle of the drill to 90°;

[0040] (2) Put the workpiece 1 from bottom to top into the guide sleeve 2 fixed on the feed pallet 3, adjust the position of the workpiece 1, so that the center line of the processed hole coincides with the center axis of the drill, and the two The coincidence error of the center line is not greater than 2.0mm;

[0041](3) Power on, the drill rod box 5 drives the drill bit 6 to rotate, so that the rotation speed of the drill bit 6 reaches 400r / min, the cutting oil is passed into the drill bit 6 through the drill rod box 5, and the flow rate of the cutting oil is 70ml / s. The workpiece 1 is moved downwards driven by the feed pallet 3, and the feed rate is 1.2mm / r until the feeding movement of drilling is completed; the workpiece is returned to the...

Embodiment 3

[0046] An operation method for fine drilling with an inverted drilling machine, the steps of the operation method are:

[0047] (1) Install the drill upside down on the drill box 5, and adjust the vertical angle of the drill to 90°;

[0048] (2) Put the workpiece 1 from bottom to top into the guide sleeve 2 fixed on the feed pallet 3, adjust the position of the workpiece 1, so that the center line of the processed hole coincides with the center axis of the drill, and the two The coincidence error of the center line is not greater than 2.0mm;

[0049] (3) Power on, the drill rod box 5 drives the drill bit 6 to rotate, so that the rotation speed of the drill bit 6 reaches 350r / min, the cutting oil is passed into the drill bit 6 through the drill rod box 5, and the flow rate of the cutting oil is 60ml / s. The workpiece 1 is moved downwards driven by the feed pallet 3, and the feed rate is 1.0mm / r until the feeding movement of drilling is completed; the workpiece is returned to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com