Casting separation mechanism and separation method

A separation mechanism and casting technology, which is applied in the casting separation mechanism and separation field, can solve the problems of cumbersome separation process of product and nozzle waste, complex blanking trough, inability to realize product and nozzle waste classification collection, etc., to achieve convenient product and waste The effect of separation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

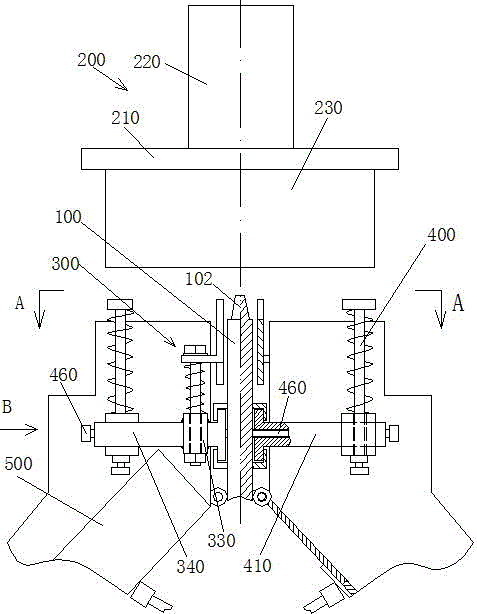

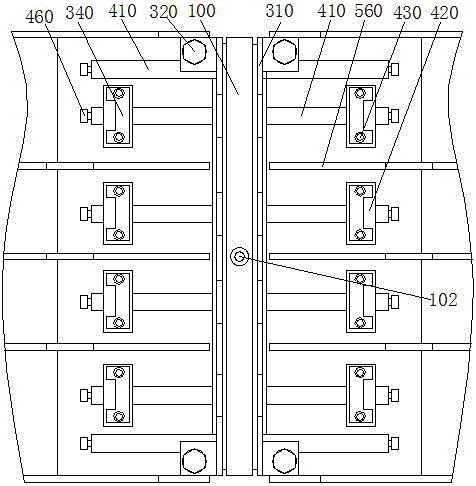

[0023] refer to Figure 1 to Figure 4

[0024] . A casting separation mechanism, including a channel plate 100 with longitudinal chute 101 respectively arranged on both sides, a liftable vibration mechanism 200 is arranged above the channel plate, and an elastic lifting mechanism 200 is provided on the upper part of the channel plate for positioning of castings. The positioning mechanism 300, the positioning mechanism cooperates with the vibrating mechanism to realize the lifting, the waste fixing device 400 that can be elastically lifted is arranged at intervals on the chute of the groove plate, and the waste fixing device cooperates with the vibrating mechanism to realize clamping The nozzle waste of the cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com