Machining method for comprehensive utilization of waste rock of Hainan Shilu iron mine

A processing method and stone technology, applied in chemical instruments and methods, solid waste removal, solid separation, etc., can solve the problems of burying fertile fields, polluting water sources, endangering the safety of people on site and surrounding people, etc., to protect the environment and reduce energy. consumption, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

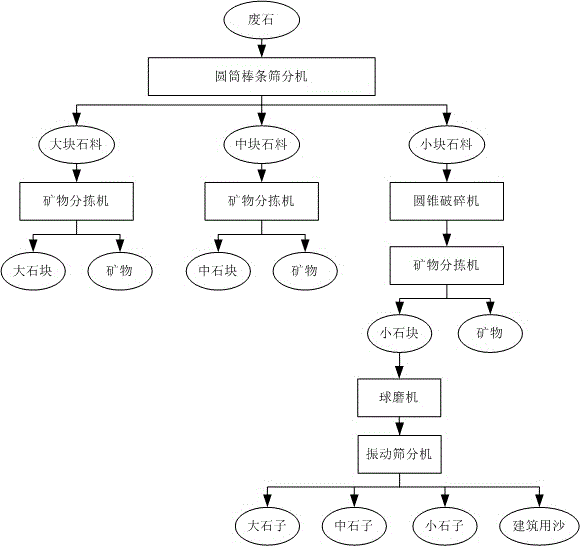

[0014] An embodiment of the processing method for the comprehensive utilization of waste rocks in Hainan Shilu Iron Mine of the present invention uses a feeder to evenly feed the waste rocks into the first screening machine, and the first screening machine screens the waste rocks into three types of stones: large Large stones, medium stones and small stones, large stones are sorted out of minerals and large stones by a mineral sorting machine, medium stones are sorted out of minerals and medium stones by a mineral sorting machine, small stones are crushed After being crushed by the machine, it is sent to the mineral sorting machine to sort out minerals and small stones, and the small stones are sent to the ball mill for grinding, and then sent to the second screening machine to screen out large, medium and small stones and construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com