Preparation method of composite filter aid for hydrochloric acid waste residue

A composite filter aid technology, applied in the field of environmental engineering, can solve the problems of small effect and narrow range, and achieve the effect of promoting reduction, reducing recycling cost, and easy configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

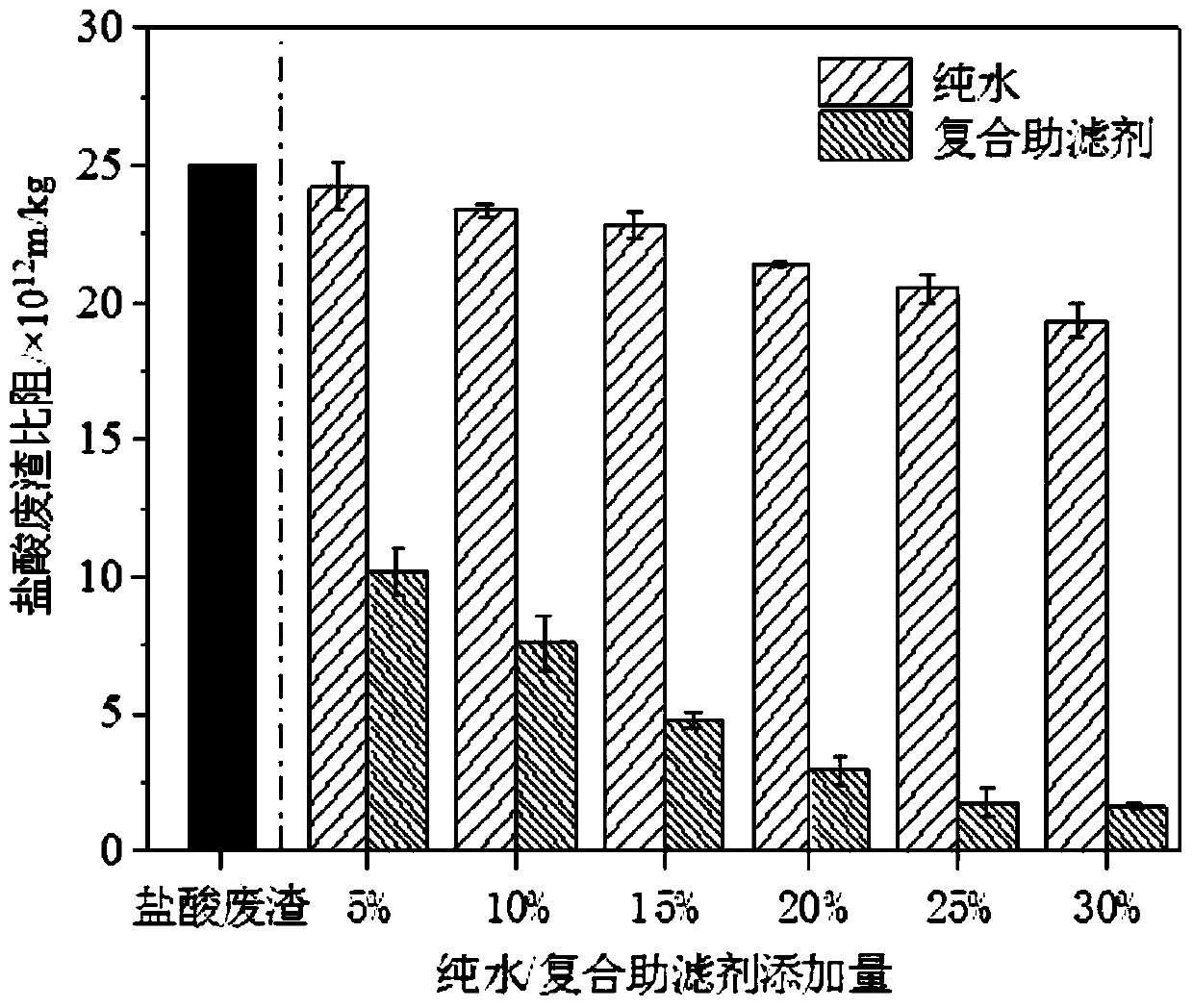

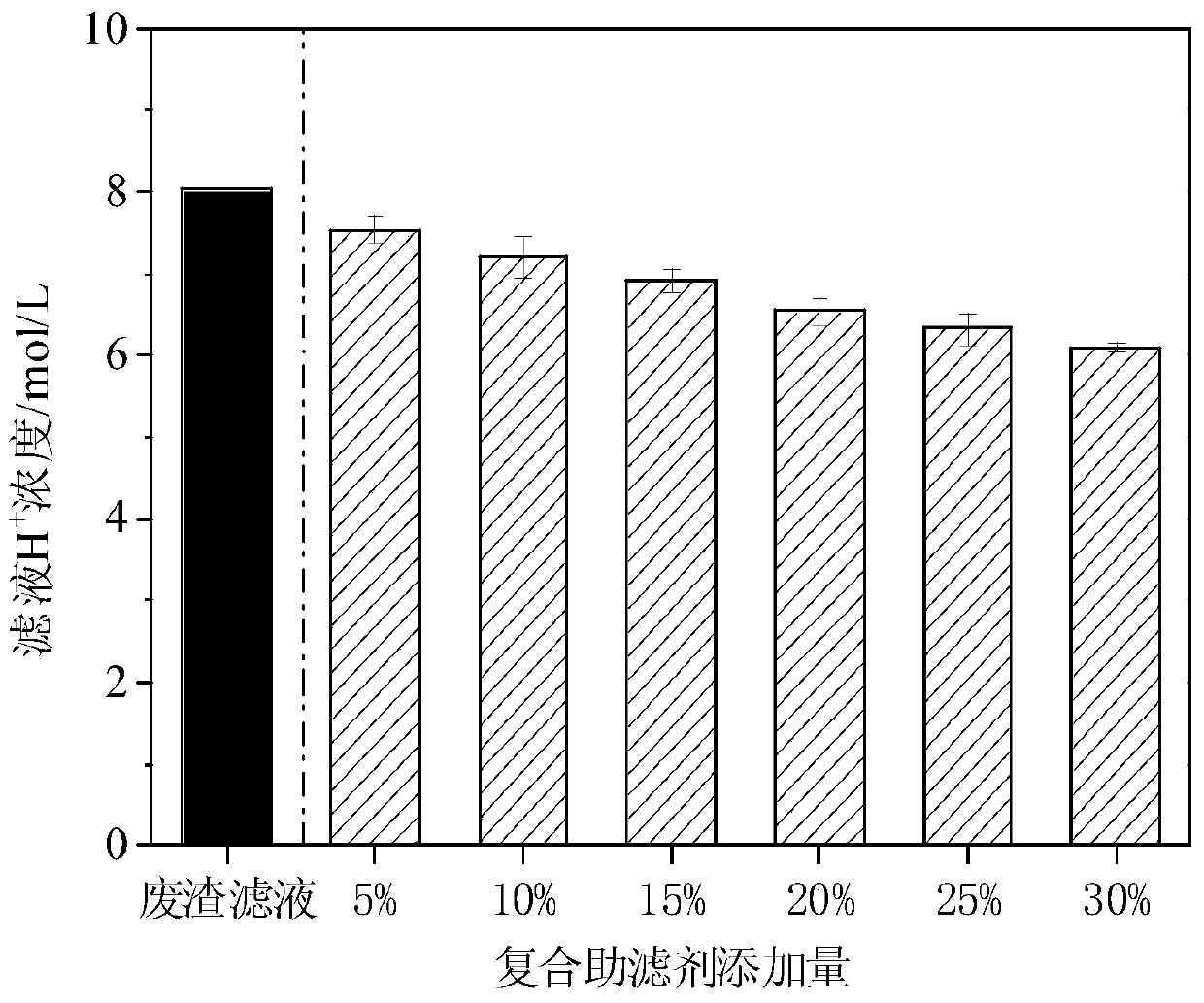

[0041] Example 1. Configuration of composite filter aid and modification of filtration performance of hydrochloric acid waste residue (indoor test)

[0042] (1) Compound filter aid preparation:

[0043] Under the conditions of stirring speed 180r / min and temperature 85-95°C, 1% concentration of polyvinyl alcohol, preferably PVA1799 solution, is pre-configured, and after cooling to normal temperature, water lost by evaporation is added by weighing method. Then accurately weigh a certain mass of polyvinylpyrrolidone according to 0.6% of the volume of the polyvinyl alcohol solution into the solution and fully stir to dissolve. After the polyvinylpyrrolidone is completely dissolved, accurately weigh a certain amount of polyethylene glycol according to 0.4% of the volume of the above polyvinyl alcohol solution, and dissolve it in the same way, and the obtained mixed solution is a composite filter aid with a concentration of 2%.

[0044] (2) Modification of hydrochloric acid waste ...

example 2

[0049] Example 2. Modification of the filtration performance of hydrochloric acid waste residue by compound filter aids (small filter press test)

[0050] In actual production and application, the moisture content of the material after dehydration can more intuitively represent its filtration and dehydration performance. Therefore, on the basis of the above test, the filter area is 0.16m 2 The 250-type chamber filter press was used to compare the deacidification effect of the modified hydrochloric acid waste residue.

[0051] (1) The specific test steps, methods and parameters are adjusted as follows:

[0052] ① Pre-dissolved in hot water at 90-95°C to obtain a 2% concentration composite filter aid solution;

[0053] ② Take some hydrochloric acid waste residue, add compound filter aid according to 25% of its volume for conditioning, add slowly while stirring, continue stirring for 2 minutes after adding, make the system fully mixed evenly, and then use a filter press to feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com