Low shrinkage dental composite resin containing organic-inorganic functional monomer and preparation method thereof

A technology for low-shrinkage dentistry and dental restoration. It is applied in dental preparations, dentistry, and dental prostheses. It can solve problems such as incomplete solvent removal and material toxicity that does not meet clinical application standards, and achieve excellent comprehensive performance and mechanical properties. Good, reduce shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

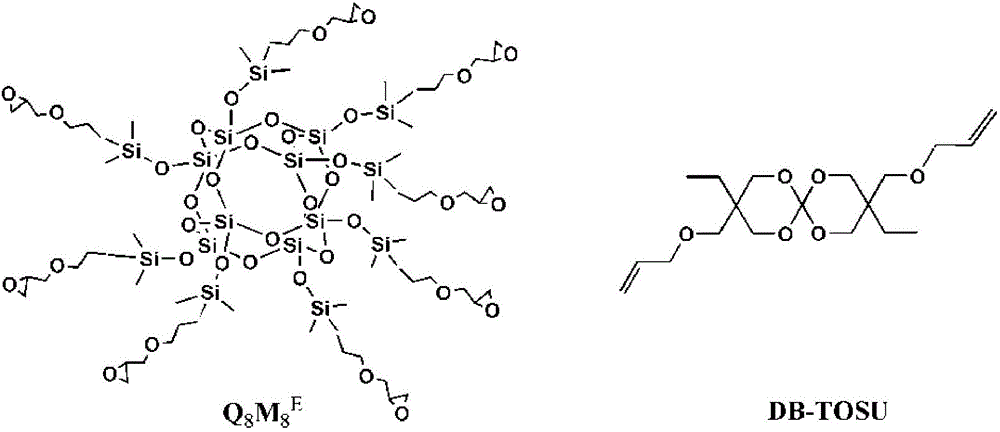

[0037] 1. Preparation of organic-inorganic polyfunctional reactive nano monomer octaepoxy group cage silsesquioxane (Q 8 m 8 E ):

[0038] (1) Add 41.0 mL of tetramethylammonium hydroxide (TMAH), 50.96 mL of methanol, and 15 mL of water into a 500 mL round bottom flask, stir in an ice bath, then add 22 mL of tetraethoxysilane (TEOS), and Stir for 24 hours;

[0039] (2) Add this mixture dropwise to another 1L three-necked flask (500mL n-hexane and 42.9mL dimethylchlorosilane (DMCS) have been added to the bottle, and the mixture is stirred at room temperature for 3h ;

[0040] (3) Separate the liquid with a pear-shaped funnel, take the upper layer liquid and rotary evaporate, filter with suction, wash with methanol for 3 times to obtain a white powder solid, dry to obtain dimethylsilyl clathrate silsesquioxane;

[0041] (4) Add 20 mL of anhydrous toluene and 2.0 g of dimethylsilyl clathrate silsesquioxane into a 100 mL three-neck flask, stir for 5 minutes, add 1.84 mL of al...

Embodiment 2

[0064] 1. Preparation of organic-inorganic polyfunctional reactive nano monomer octaepoxy group cage silsesquioxane (Q 8 m 8 E ):

[0065] Preparation method is with embodiment 1;

[0066] 2. Preparation of spiro ring expansion monomer 3,9-diethyl-3,9 propenyloxymethyl-1,5,7,11-tetraoxaspiro[5,5]undecane (DB-TOSU) :

[0067] Preparation method is with embodiment 1;

[0068] 3. Preparation of silanized micron silica:

[0069] Preparation method is with embodiment 1;

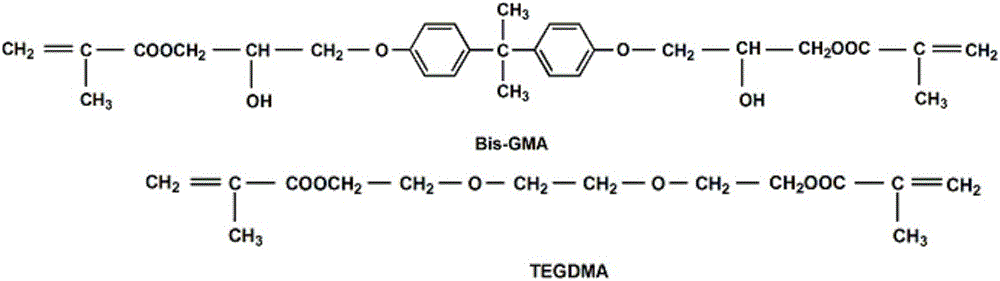

[0070] 4. Mix bisphenol A-glycidyl methacrylate (Bis-GMA) and triethylene glycol dimethacrylate (TEGDMA) evenly in a weight ratio of 7:3 to form a resin matrix for later use;

[0071] 5. Measure 15.2g of resin matrix into a 50mL beaker, add 0.26g of octaepoxy cage silsesquioxane (Q 8 m 8 E ), 0.54g 3,9-diethyl-3,9 propenyloxymethyl-1,5,7,11-tetraoxaspiro[5,5]undecane (DB-TOSU), stir well, ultrasonic 0.5h;

[0072] 6. Add 0.4g camphorquinone (CQ), 0.4g ethyl p-dimethylaminobenzoate (EDAB), 0.4g diphenyl...

Embodiment 3

[0078] 1. Preparation of organic-inorganic polyfunctional reactive nano monomer octaepoxy group cage silsesquioxane (Q 8 m 8 E ):

[0079] Preparation method is with embodiment 1;

[0080] 2. Preparation of spiro ring expansion monomer 3,9-diethyl-3,9 propenyloxymethyl-1,5,7,11-tetraoxaspiro[5,5]undecane (DB-TOSU) :

[0081] Preparation method is with embodiment 1;

[0082] 3. Preparation of silanized micron silica:

[0083] Preparation method is with embodiment 1;

[0084] 4. Mix bisphenol A-glycidyl methacrylate (Bis-GMA) and triethylene glycol dimethacrylate (TEGDMA) evenly in a weight ratio of 7:3 to form a resin matrix for later use;

[0085] 5. Measure 13.6g of resin matrix into a 50mL beaker, add 0.8g of octaepoxy cage silsesquioxane (Q 8 m 8 E ), 1.6g 3,9-diethyl-3,9propenyloxymethyl-1,5,7,11-tetraoxaspiro[5,5]undecane (DB-TOSU), stir well, ultrasonic 0.5h;

[0086] 6. Add 0.4g camphorquinone (CQ), 0.4g ethyl p-dimethylaminobenzoate (EDAB), 0.4g diphenyliod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com