A method for estimating the hot air temperature of a setting machine using the heat of heat conduction oil as the heat source

A technology of heat conduction oil and machine hot air, which is applied in computing, special data processing applications, instruments, etc. It can solve problems such as poor temperature control accuracy, lack of understanding of the relationship between flow and temperature of the shaping machine, poor product shaping effect, etc. , to achieve the effect of reducing hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

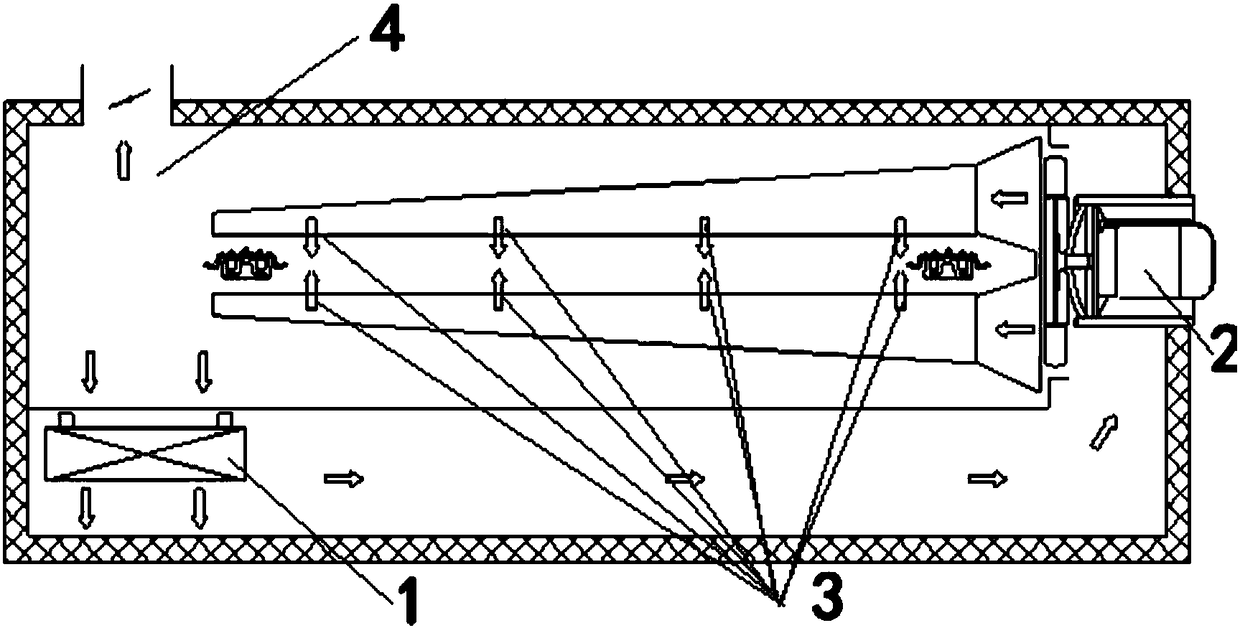

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

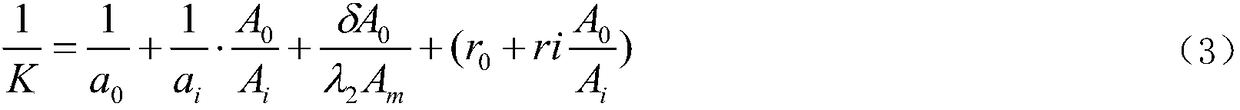

[0060] A method for estimating the hot air temperature of a sizing machine using heat transfer oil as a heat source, comprising the following steps: 1) introducing heat transfer oil into a shell-and-tube heat exchanger 1 to make it circulate inside the shell-and-tube heat exchanger 1 to circulate air It circulates outside the shell-and-tube heat exchanger 1 and circulates through the hot air circulation fan 2. According to the law of heat conservation, it can be obtained:

[0061] Q = ρ oil u oil C oil (T 1 -T 2 ) (1)

[0062] Q = ρ air u air C air (t 2 -t 1 ) (2)

[0063] The symbol ρ here represents the density, u represents the flow rate, and C represents the specific heat, that is, ρ oil Indicates the density of heat transfer oil, ρ air Indicates the density of air, u oil Indicates the flow rate of heat transfer oil, u air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com