A kind of modified environmental protection carbon and its preparation method and application

An environmentally friendly and modified technology, applied in applications, chemical instruments and methods, and other chemical processes, etc., can solve problems such as poor snow melting effect and organic pollution to the environment, achieve strong snow melting and ice melting ability, promote plant growth, and reduce corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

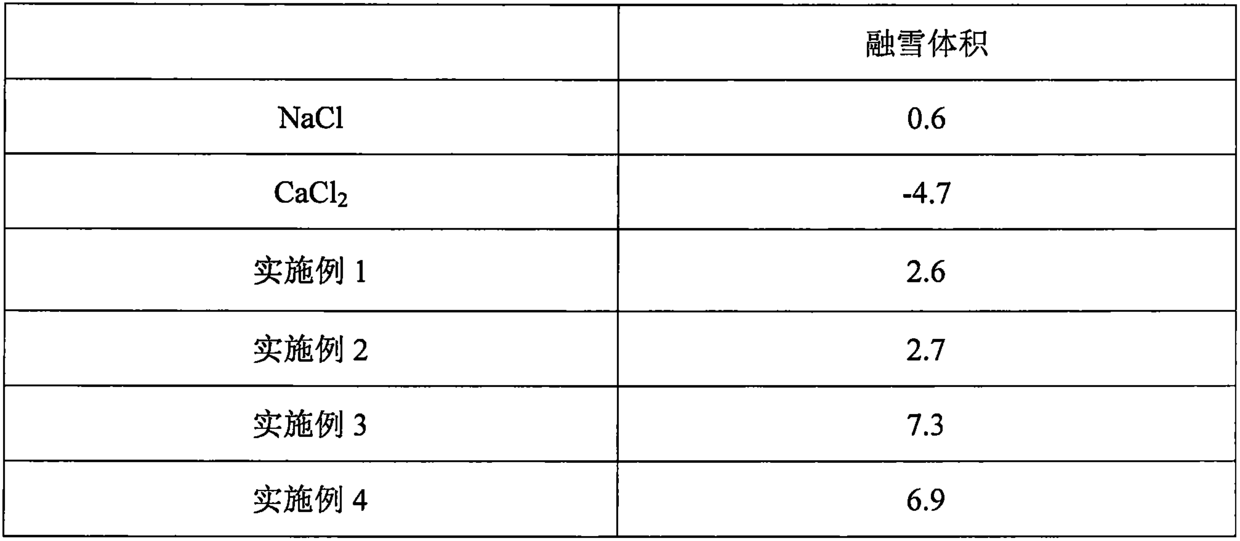

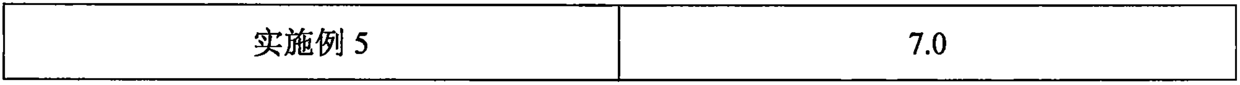

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a preparation method of modified environmental protection carbon consists of the following steps:

[0019] 1) Put the charcoal into a pulverizer to pulverize it, and pass it through an 80-mesh sieve to obtain charcoal powder.

[0020] 2) Banana water, cyclohexane and ethanol are mixed to prepare a mixed solution, wherein the mass ratio of banana water, cyclohexane and alcohol is 1:12:30.

[0021] 3) Grinding the rosin into powder and passing through a 120-mesh sieve to obtain rosin powder.

[0022] 4) Mix the mixed solution, rosin powder and charcoal powder, the mass ratio of the mixed solution, rosin powder and charcoal powder is 35:3:22; after stirring for 20 minutes, heat up to 75°C, seal and stir for 60 minutes, and add concave and convex after cooling down to room temperature Palygorda, wherein the mass ratio of attapulgite to charcoal powder is 1:2.2, after stirring for 20 minutes, heat up to 88°C, seal and stir for 30 ...

Embodiment 2

[0024] In the embodiment of the present invention, a preparation method of modified environmental protection carbon consists of the following steps:

[0025] 1) Put the charcoal into a pulverizer to pulverize it, and pass it through a 100-mesh sieve to obtain charcoal powder.

[0026] 2) Banana water, cyclohexane and ethanol are mixed to prepare a mixed solution, wherein the mass ratio of banana water, cyclohexane and alcohol is 1:15:35.

[0027] 3) Grinding the rosin into powder and passing through a 150-mesh sieve to obtain rosin powder.

[0028] 4) Mix the mixed liquid, rosin powder and charcoal powder, the mass ratio of the mixed liquid, rosin powder and charcoal powder is 45:5:28; after stirring for 25 minutes, heat up to 78°C, seal and stir for 75 minutes, and add concave and convex after cooling down to room temperature Palygorda, wherein the mass ratio of attapulgite to charcoal powder is 1:3.5. After stirring for 25 minutes, heat up to 92°C, seal and stir for 35 minu...

Embodiment 3

[0030] In the embodiment of the present invention, a preparation method of modified environmental protection carbon consists of the following steps:

[0031] 1) Put the charcoal into a pulverizer to pulverize it, and pass it through a 100-mesh sieve to obtain charcoal powder.

[0032] 2) Banana water, cyclohexane and ethanol are mixed to prepare a mixed solution, wherein the mass ratio of banana water, cyclohexane and alcohol is 1:14:32.

[0033] 3) Grinding the rosin into powder and passing through a 150-mesh sieve to obtain rosin powder.

[0034] 4) Mix the mixed solution, rosin powder and charcoal powder, the mass ratio of the mixed solution, rosin powder and charcoal powder is 40:4:25; after stirring for 22 minutes, heat up to 77°C, seal and stir for 68 minutes, and add concave and convex after cooling down to room temperature Palygorda, in which the mass ratio of attapulgite to charcoal powder is 1:3, after stirring for 22 minutes, heat up to 90°C, seal and stir for 32 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com