Method for preparing biochar by hydrothermal carbonization of shaddock peel and application thereof

A hydrothermal carbonization, grapefruit peel technology, applied in chemical instruments and methods, biofuels, alkali metal compounds, etc., can solve the problem of no grapefruit peel biochar and other problems, achieve the preparation method is simple and easy to operate, reduce costs, and solve the problem of high added value The effect of value resource utilization problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

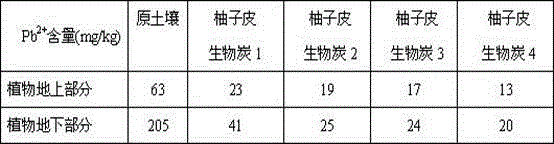

Embodiment 1

[0025] The raw grapefruit peel is pretreated to remove the impurities on the surface, and it is broken into pieces with a length of 2-5 cm and a width of 1-3 cm with a cutter. The broken grapefruit peel and deionized water are 1 kg: 20 L Proportion mixing, then transferred to a closed high-pressure reactor, hydrothermal carbonization treatment at 180 ℃, the reaction time is 10 hours, after the hydrothermal reaction is cooled to room temperature, vacuum pump filtration to obtain biochar with a water content of 20-40 wt% , Air-dried to a moisture content of less than 20 wt%, dried in an oven at a temperature of 105 ℃ for 4 hours, the moisture content was reduced to less than 5%, then crushed and sieved to 1-5 mm to obtain grapefruit peel biochar 1.

Embodiment 2

[0027] The raw grapefruit peel is pretreated to remove the impurities on the surface, and it is broken into pieces with a length of 2-5 cm and a width of 1-3 cm with a cutter. The broken grapefruit peel and deionized water are 1 kg: 20 L Proportion mixing, doping catalyst metal salt FeCl in deionized water 3 , Catalyst metal salt FeCl 3 The doping ratio with deionized water is the catalyst metal salt FeCl 3 : Deionized water = 1g: 15 L, then the solid-liquid mixture is transferred to a closed autoclave, and hydrothermally carbonized at 180 ℃. The reaction time is 10 hours. After the hydrothermal reaction is completed, it is cooled to room temperature and filtered by a vacuum pump to obtain water Biochar with a rate of 20-40 wt%, air-dried until the moisture content is below 20 wt%, and then dried in an oven at 105 ℃ for 4 hours, the moisture content is reduced to below 5%, and then crushed and sieved to 1- 5 mm, get grapefruit peel biochar 2.

Embodiment 3

[0029] The hydrothermal carbonization treatment was carried out under the condition of 260°C, and the others were the same as in Example 2, and the grapefruit peel biochar 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com