A molding method of complex ceramic parts based on the principle of quick-setting wax spray

A technology of ceramic parts and molding methods, applied in the field of investment precision casting, to achieve the effects of good surface quality, high precision, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

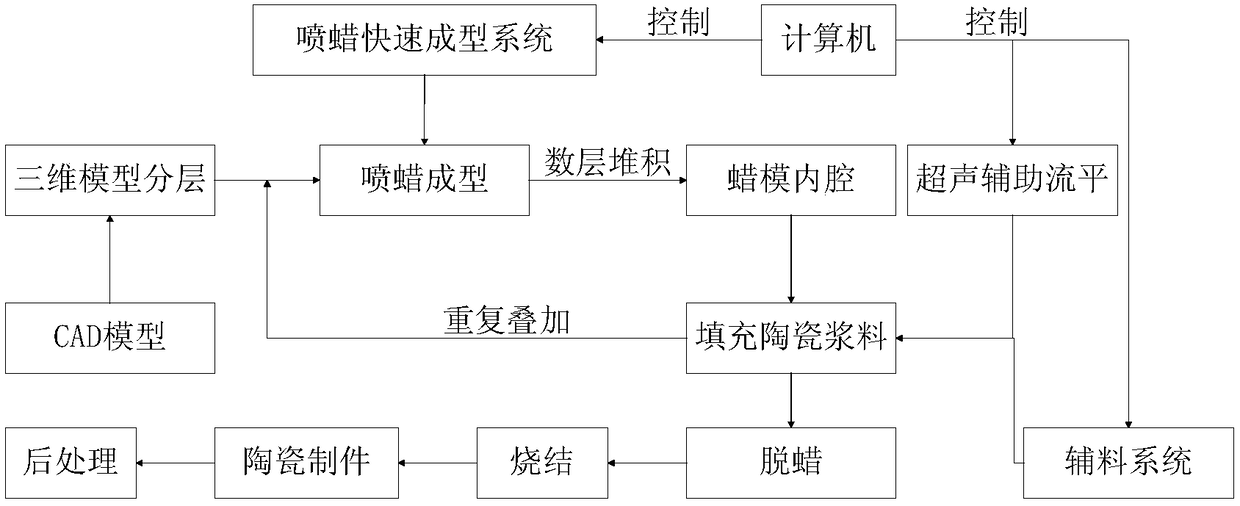

[0025] Such as figure 1 As shown in, the present invention provides a method for forming complex ceramic parts based on the principle of quick-setting wax spray, which specifically includes the following steps:

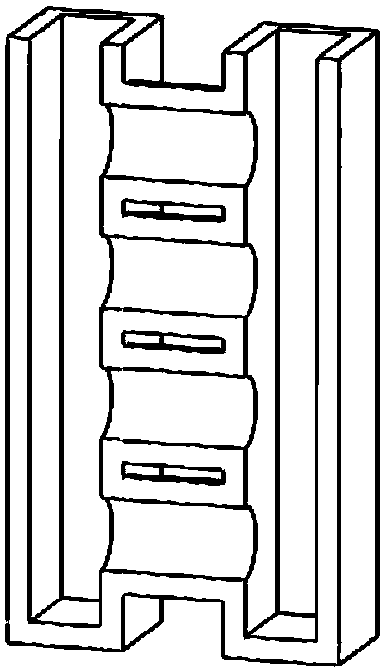

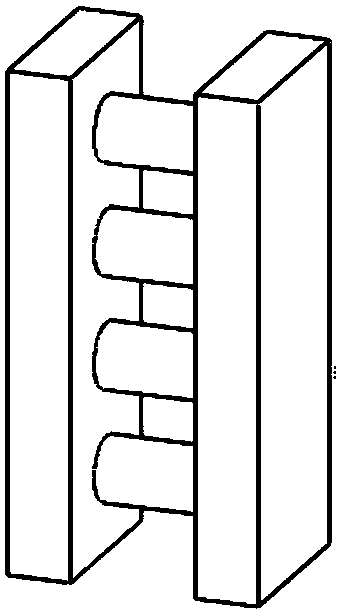

[0026] First use Pro / E or Solidworks software to construct the three-dimensional data model of the wax model, the data model is as follows figure 2 as shown ( image 3 for figure 2 ceramic part formed from the wax pattern shown). will subsequently figure 2 The model shown in is stored as an STL format file. In the next step, the layering software of the wax spray rapid prototyping system is used for layering processing, and the thickness of each layer is set, that is, the height of each wax mold cavity. The layer thickness is generally 0.02-2.00mm; according to the surface roughness of the part Requirements, select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com