Technological process of making silicon carbide ceramic part based on smelting deposition and fast forming techn

A technology of silicon carbide ceramics and fused deposition, which is applied in the new technology field of ceramic parts, can solve the problems of poor plasticity of silicon carbide materials, difficulty in meeting requirements, and plastically formed parts, etc., and achieves the goal of improving development speed and high dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

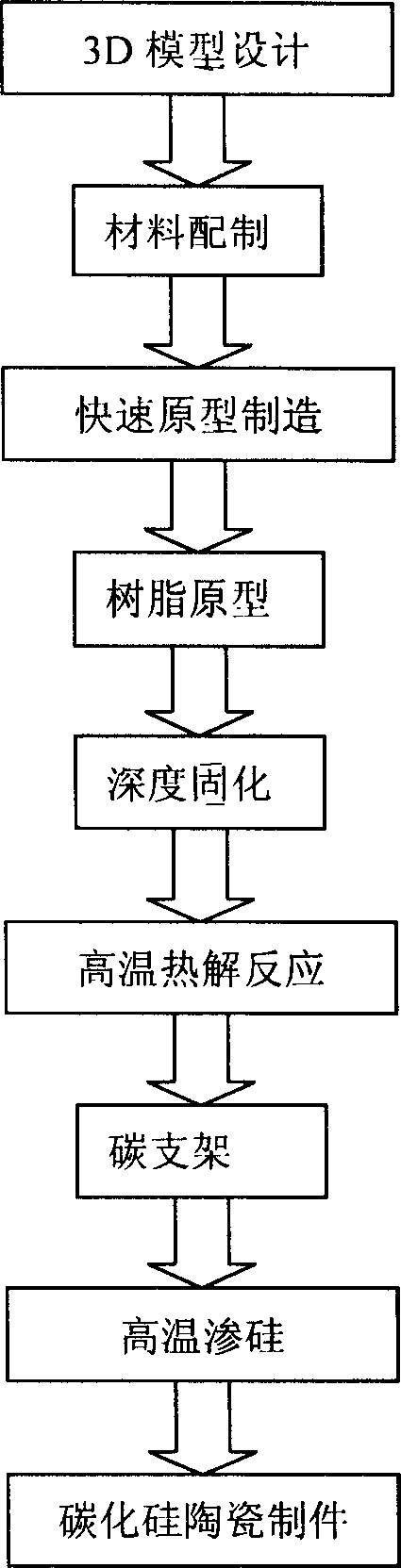

[0021] see figure 1 , process step of the present invention comprises:

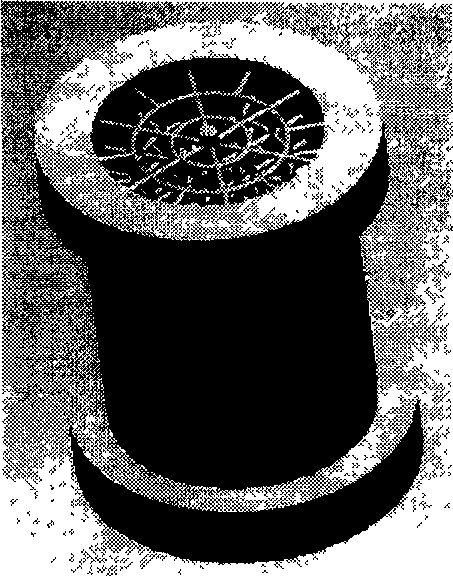

[0022] 1. 3D model design step, according to actual requirements, use Pro / E software to construct the 3D data model of the workpiece, such as figure 2 shown; and figure 2 The model shown is stored as an STL format file;

[0023] 2. Use the layering software that comes with the rapid prototyping machine to do layering processing, and import the processed data into the manufacturing program; the above steps are mature technologies in this field.

[0024] 3. Take 100g of 2130# phenolic resin, 20g of starch, and 8g of benzenesulfonyl chloride into a container, and stir with a stirrer for 10 minutes to make it evenly mixed to make raw materials.

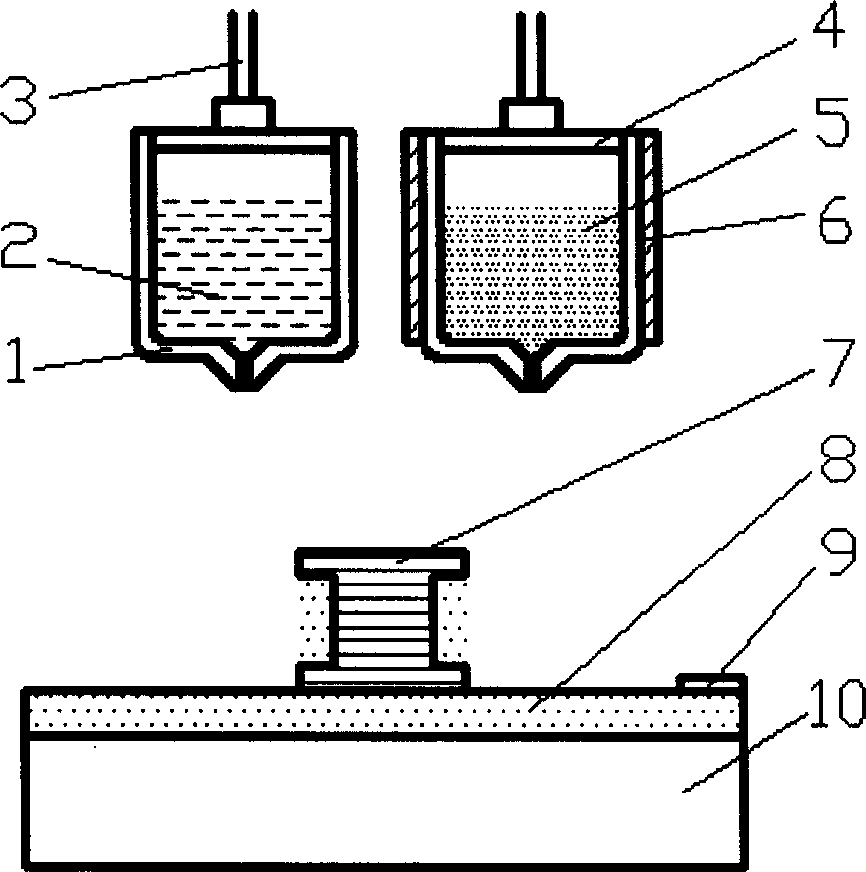

[0025] 4. If image 3 As shown, the phenolic resin prototype was fabricated on the FDM rapid prototyping machine of Xi'an Jiaotong University. Pour the phenolic resin mixture 2 prepared in step 3 into the nozzle I (1), add polyethylene particles into the nozzl...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is that in step 4, the movement speed of the three-dimensional workbench 10 is set to 25mm / s, the carbonization temperature in step 6: 1000°C, and the holding time: 0.5h; in step 7, The particle size of Si powder is 50 μm, the reaction temperature is 1550° C., the holding time is 1 h, and the rest are the same as in Example 1.

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that in step 4, the movement speed of the three-dimensional workbench 10 is set to 20mm / s, the carbonization temperature in step 6: 1000°C, and the holding time: 0.5h; Si powder particle size is 75μm, reaction temperature: 1500°C, holding time: 1h, the rest are the same

[0035] Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com