Technical method for rapid shaping silicon carbide ceramic part utilizing laminated solid body

A technology of silicon carbide ceramics and process methods, applied in the new process field of ceramic components, can solve problems such as the complexity of the shape cannot meet the requirements, and achieve the effect of increasing the development speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

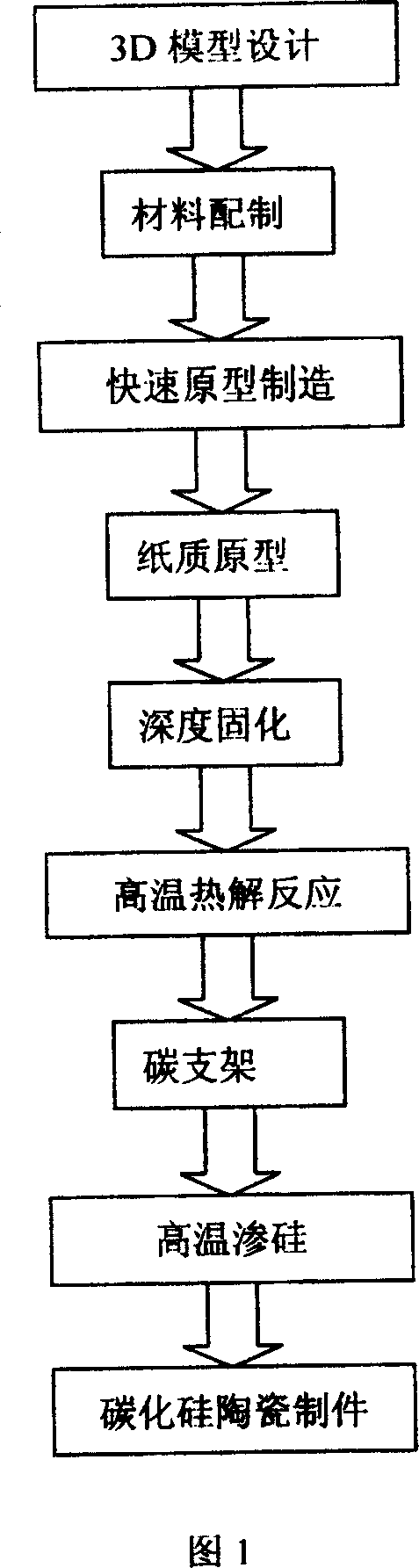

[0020] Referring to Fig. 1, present embodiment is raw material with paper and phenolic resin, and its processing step comprises:

[0021] 1.3D model design step, according to actual requirements, use Pro / E software to construct the three-dimensional data model of the workpiece, as shown in Figure 2; and store the model shown in Figure 2 as an STL format file;

[0022] 2. Use the layering software that comes with the rapid prototyping machine to do layering processing, and import the processed data into the manufacturing program; the above steps are mature technologies in this field.

[0023] 3. Use 2130# phenolic resin and add benzenesulfonyl chloride with a weight ratio of 4% to mix evenly as the interlayer adhesive.

[0024] 4. Create a rapid prototype of the paper precursor on the rapid prototyping machine.

[0025] 5. Put the manufactured paper precursor rapid prototype into an oven to deeply cure the phenolic resin binder. The initial temperature of the oven was set at ...

Embodiment 2

[0030] The difference between this example and Example 1 is that in step 6, the carbonization temperature is 1000°C, and the holding time is 0.5h; in step 7, the particle size of Si powder is 50 μm, the reaction temperature is 1550°C, and the holding time is : 1h, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com